Application of information technology is a global trend. While water treatment is a complicated process, its increasing complexity warrants consideration of automated technology to enhance efficiency, long-term stability and sustainability. Experienced chemists possess professional judgement in water quality monitoring, so, in recent years, the Water Science Division of the WSD has been endeavouring to build from chemists’ knowledge and experience to gradually develop scientific and technological systems for automating more processes. This will give the water quality control process greater intelligence, and enable swifter and smarter decision-making and responses.

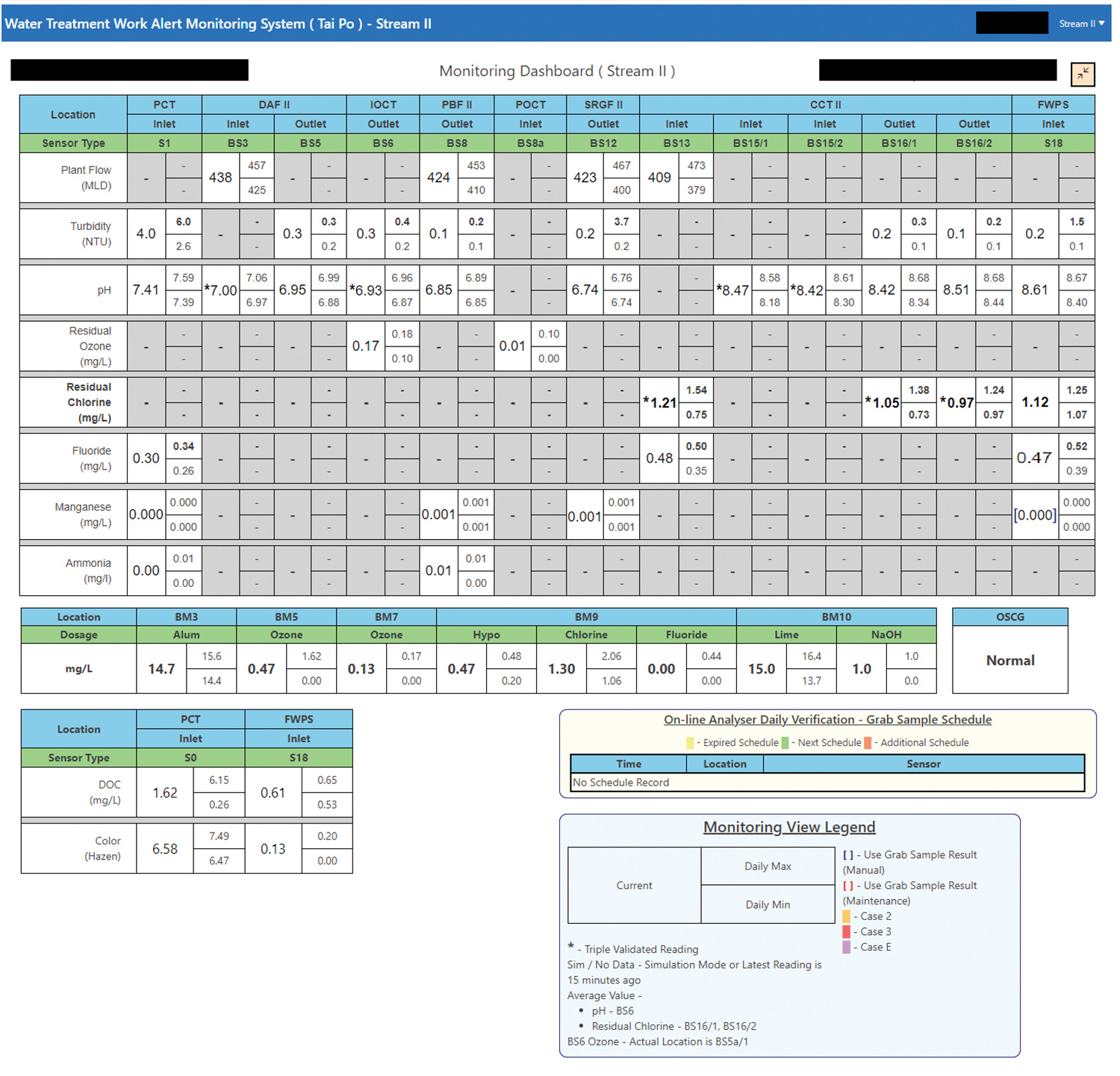

Water treatment works treat raw water to meet quality requirements at different stages and finally produce drinking water that is in full compliance with the Hong Kong Drinking Water Standards before supplying to the customers. The water treatment process involves monitoring of nearly 100 parameters. Currently, the water treatment works use electronic sensors to collect the required monitoring data and these are all simultaneously transmitted to the control room for overview by waterworks staff with real-time information on screens. The system is designed to set different levels of upper and lower limit indicators for each parameter. When the parameter value exceeds any limit, different alarms from the system will be triggered to alert waterworks staff for follow-up action. Apart from electronic water quality sensors, water samples are also tested manually at regular intervals to verify the accuracy of the online water quality data.

System Advancement and Automation

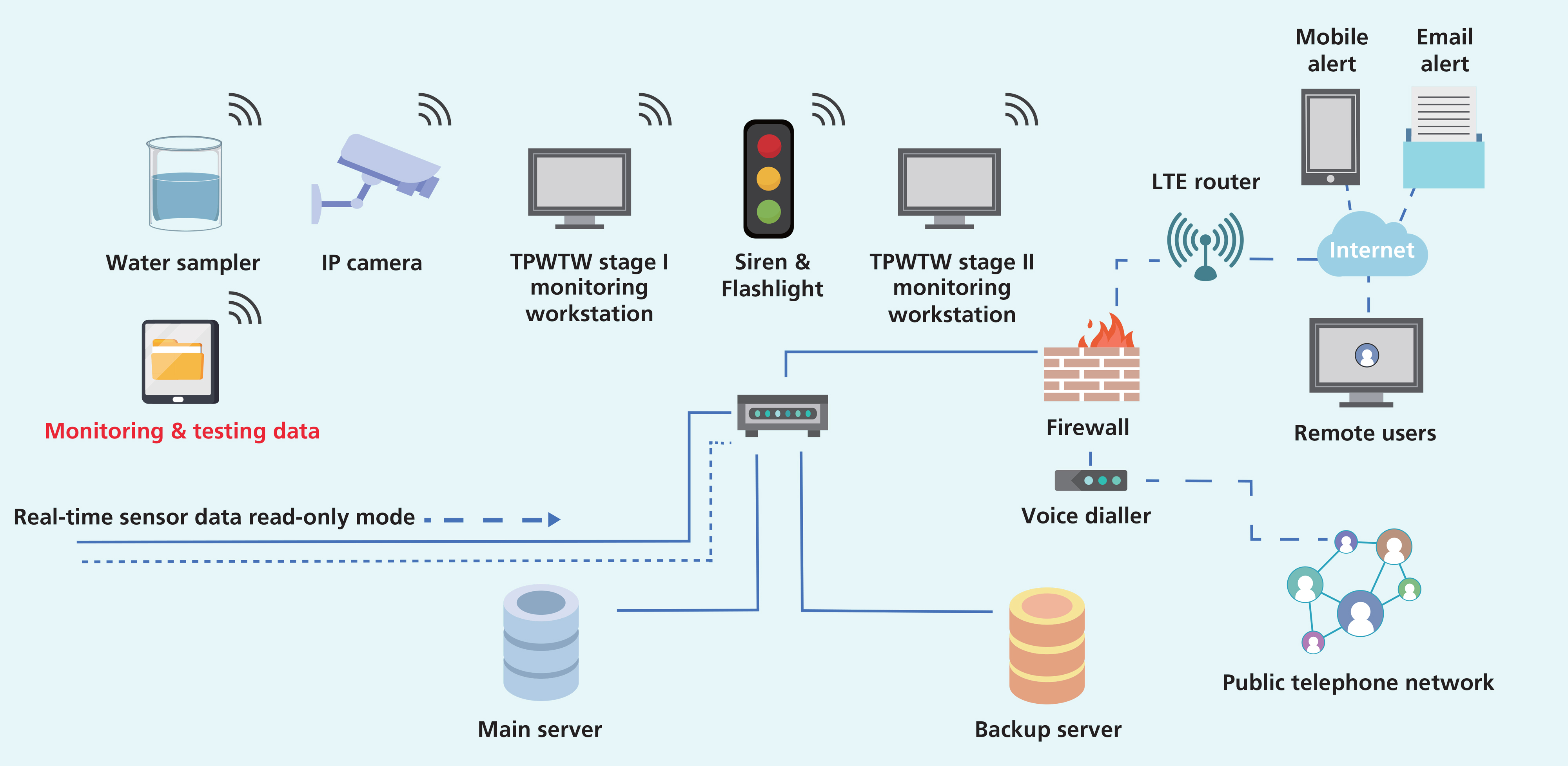

Given the multitude of parameters and variables involved at different treatment stages, coupled with the need to adjust chemical dosages to process water quality, the Water Science Division has spent three years to develop its own “Integrated Treatment Information & Tele-Alert System (INTEL)”, which incorporates various Internet of Things (IoT) technologies and automation techniques, including Optical Character Recognition (OCR) technology, which simplifies the manual data entry process by waterworks staff when reviewing data. This not only reduces human error, but also automatically collects and consolidates data for simultaneous verification. In the event of water quality changes, the system will immediately alert personnel with the latest information electronically, allowing remote access to data at any time for timely responses. Given the vast physical area and limited manpower in water treatment works facilities, the development of information technology to enable remote control and automation of the system ushers in a new era of waterworks operation.

Senior Waterworks Chemist, TANG Ki-lai, who was involved in the development of the new system, explains that there are numerous monitoring parameters and data in the operation of water treatment works. Traditional monitoring systems rely on the duty staff to screen and analyse the data. When an alert is raised, staff workload will be stretched, and if it turns out to be a false alarm, manpower will be wasted. He explains, “In fact, the exceedance of parameters is a general trigger. In particular, the extent and duration of parameters exceeding the requirements, their occurrence at different stages, and the underlying reasons, all impact treated water quality differently, necessitating varied response measures and intensities.” Consequently, the water monitoring team began researching ways to improve the system by introducing Artificial Intelligence (AI) technology. Gradually, they transferred the chemists’ practical experience into hierarchical and computer-recognised instructions, thus enriching the system’s analytical and responsive capabilities.

The WSD is responsible for 99.9% of Hong Kong's drinking water supply, making its water quality monitoring expertise unparalleled. Therefore, during the research and development of new systems, knowledge was transferred and shared, making the best use of technology by integrating the information and experience from people from different ranks and fields.

Tang says that the water quality monitoring system is now moving into a new phase of three-dimensional virtual reality. In recent years, the construction industry has also moved into a new technological era, with design of development projects being presented in Building Information Modelling (BIM). The system can be described as a 3-D image of design drawings that gives even non-professionals a glimpse of any uncompleted project.” The recent design and expansion of water treatment works, such as the Stream II of Tai Po Water Treatment Works, the South Works of Sha Tin Water Treatment Works and the Tseung Kwan O Desalination Plant, have already been developed using 3-D image-building models. Ways to integrate the water quality monitoring system into the models is now being explored. This will allow the sensor readings to be displayed directly at the corresponding locations in the virtual model, providing an overview of the data and facilitating monitoring and tracking by the water monitoring operators.

The waterworks staff are integrating, on an as-needed basis, various types of popular information technology into "Digital Twin", which is a recent modular application proposed by the technology industry. It is a virtual model presenting a physical system in a one-stop information platform, like a twin in the digital world. (Please refer to the article "Digital Twin Technology to Enhance Water Supply Management" in Chapter 3 for more information on how digital twin technology can be applied in water services.)

Conceptual Plan of the INTEL System at the Water Treatment Works