As the water treatment works operate continuously 24-hour a day, it is necessary to make well-thought-out plans for all new construction works to avoid any interruption to the usual water supply. The Sha Tin Water Treatment Works (STWTW) mentioned previously was specifically reprovisioned in-situ to reduce the impact of its expansion. Also, to ensure a continuous flow of fresh water supply during the suspension of the South Works of STWTW, the expansion works of Tai Po Water Treatment Works (TPWTW) commenced in 2013 to increase its output capacity from an average of 400,000 cubic metres (m³) per day to 800,000 m³ per day to meet growing water demand in Tai Po, Central and Western Kowloon, and the Central and Western District of Hong Kong Island.

The expansion of TPWTW doubles its volume of treated water. However, the available site areas were very limited with hilly terrain. Careful planning and execution of the design and construction processes of the facilities are therefore required. Traditionally, water treatment plants in Hong Kong are single-storey buildings. However, due to the site’s geographical constraints, TPWTW has adopted a multi-level building design to accommodate treatment facilities with a smaller footprint. An advanced dissolved air flotation technology has been chosen because the traditional sedimentation method requires a larger footprint and has a longer water treatment time. Dissolved air flotation is a clarification method that pumps compressed air into the water for producing a large quantity of micro air bubbles that adhere to suspended matter in water, creating a layer of sludge blanket. This layer is then removed by an automated sludge-scraper and by using this process, the water treatment rate is accelerated, allowing more raw water to be treated in a smaller plant. The introduction of this space-efficient design and new technology allows the facility to be reduced in size by 32% from the 20.5 hectares estimated at the investigation stage to its current 14 hectares. The project won the International Water Association Project Innovation Award in 2006.

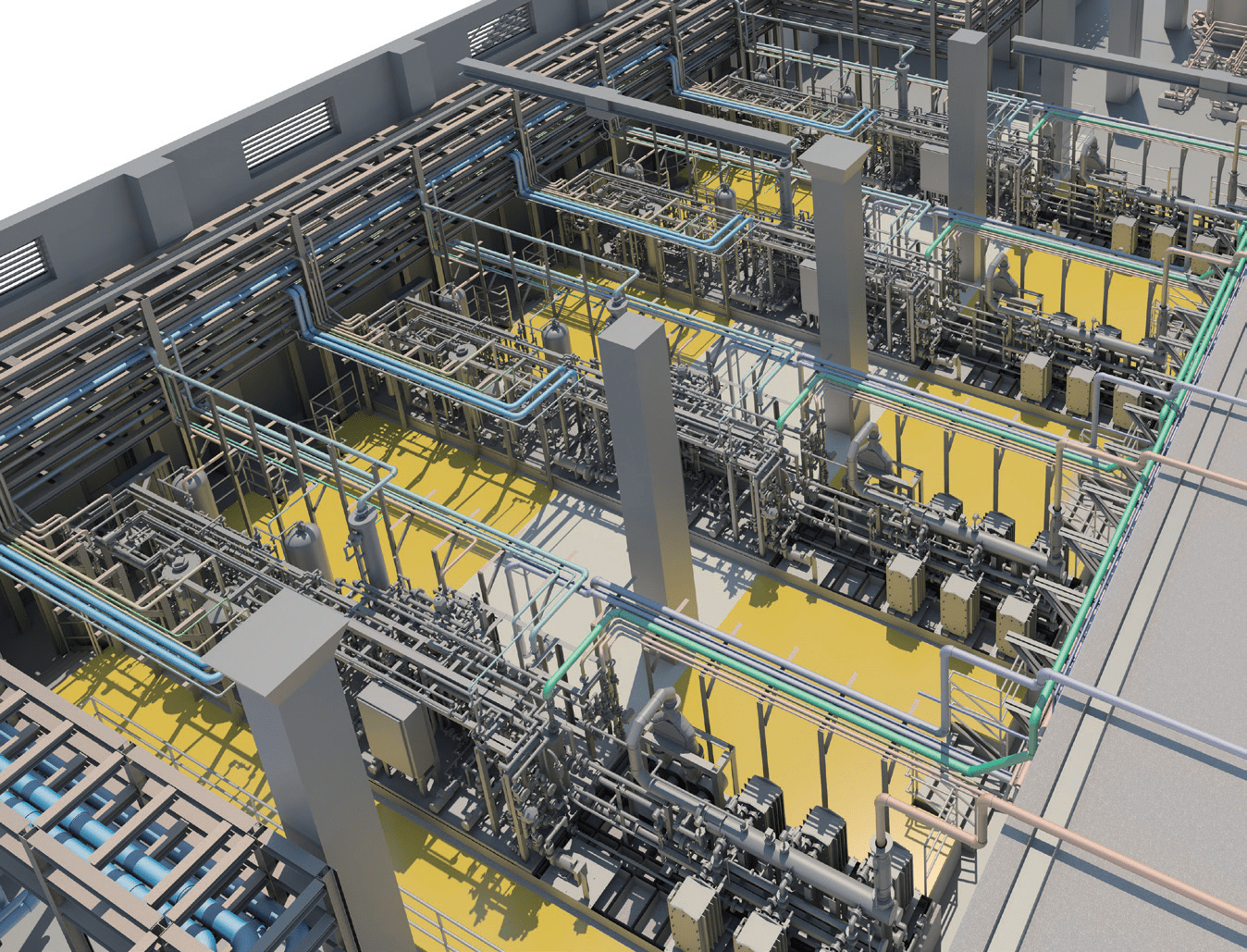

At the time of completion of expansion, the TPWTW had the first large-scale on-site chlorine generation facility in Hong Kong. It was also the first occasion that the project team performed a hazard and operability analysis assessment using Building Information Modelling (BIM). This exercise made it possible to review and identify any issues at the design stage. Compared to conventional 2-D drawings, 3-D drawings allow for the visualisation of equipment and its surrounding space, whilst also helping simulate anomalies, reduce speculation and enhance project efficiency.

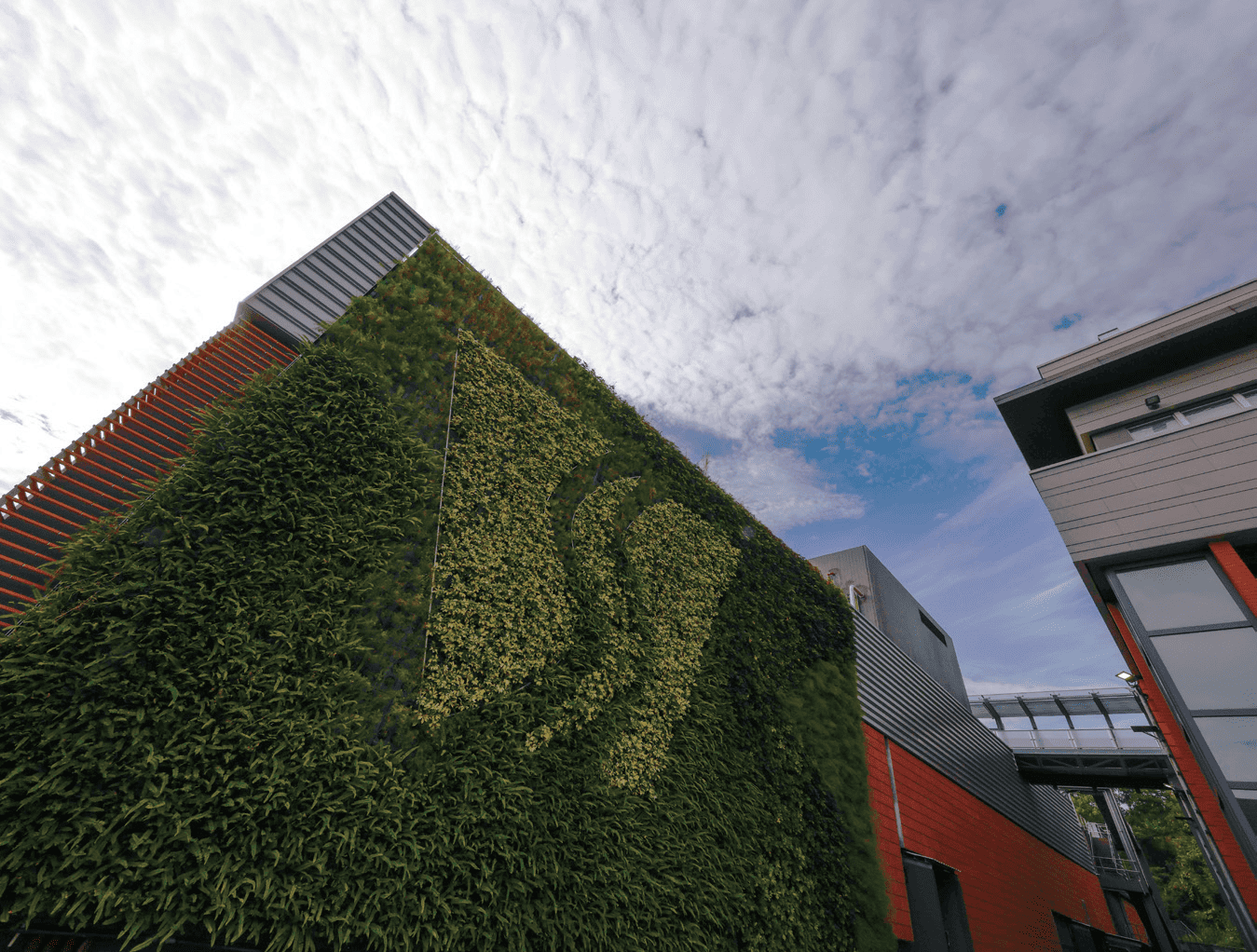

The expansion of the TPWTW also signifies the WSD's commitment to sustainable development while upgrading the water supply facilities in Hong Kong. Sustainable solutions were developed during the process, making it the first water treatment facility to attain the Final Platinum rating under the Building Environmental Assessment Method (BEAM) Plus. BEAM Plus is a Hong Kong-based certification for promoting green buildings in Hong Kong. It establishes a comprehensive set of performance criteria for a wide range of sustainability issues relating to the planning, design, construction, management, operation and maintenance of a building. The assessment results are recognised and certified by the Hong Kong Green Building Council.

A number of unique elements have been incorporated into the expansion of TPWTW, with environmental protection solutions such as greening, energy and water conservation for both old and new buildings, including the following:

Zero Effluent Discharge

Effluent generated during the treatment process, such as the backwash water, water samples that have been tested for water quality, and rainwater harvested from the roof of the new building, can be used for irrigation and flushing purposes after appropriate treatment. Based on the average rainfall in 2015/16 and the estimated water consumption of the water treatment works, the amount of effluent collected from the TPWTW could provide 40,000 m³ of recycled water for the treatment works. TPWTW also collects water from filtration through a sludge press, which further reduces water loss and achieves a raw water conversion efficiency of 99.7%. With its outstanding performance in water use, TPWTW received full marks in all eight of the water scoring categories.

Optimising the Use of Sludge from Water Treatment Works

The sludge generated during the treatment process has its water removed and is turned into sludge cake for disposal at landfills. After the expansion, the volume of sludge generated at TPWTW has doubled. To optimise the use of the sludge, the project team commissioned universities to conduct feasibility studies on the reuse of the sludge. The study found that the sludge contains certain nutrients and can improve the pH value of soil, thus helping to improve soil quality. The sludge generated from the treatment works, together with the remaining 0.3% of raw water, has been used for greening and planting within the treatment works.

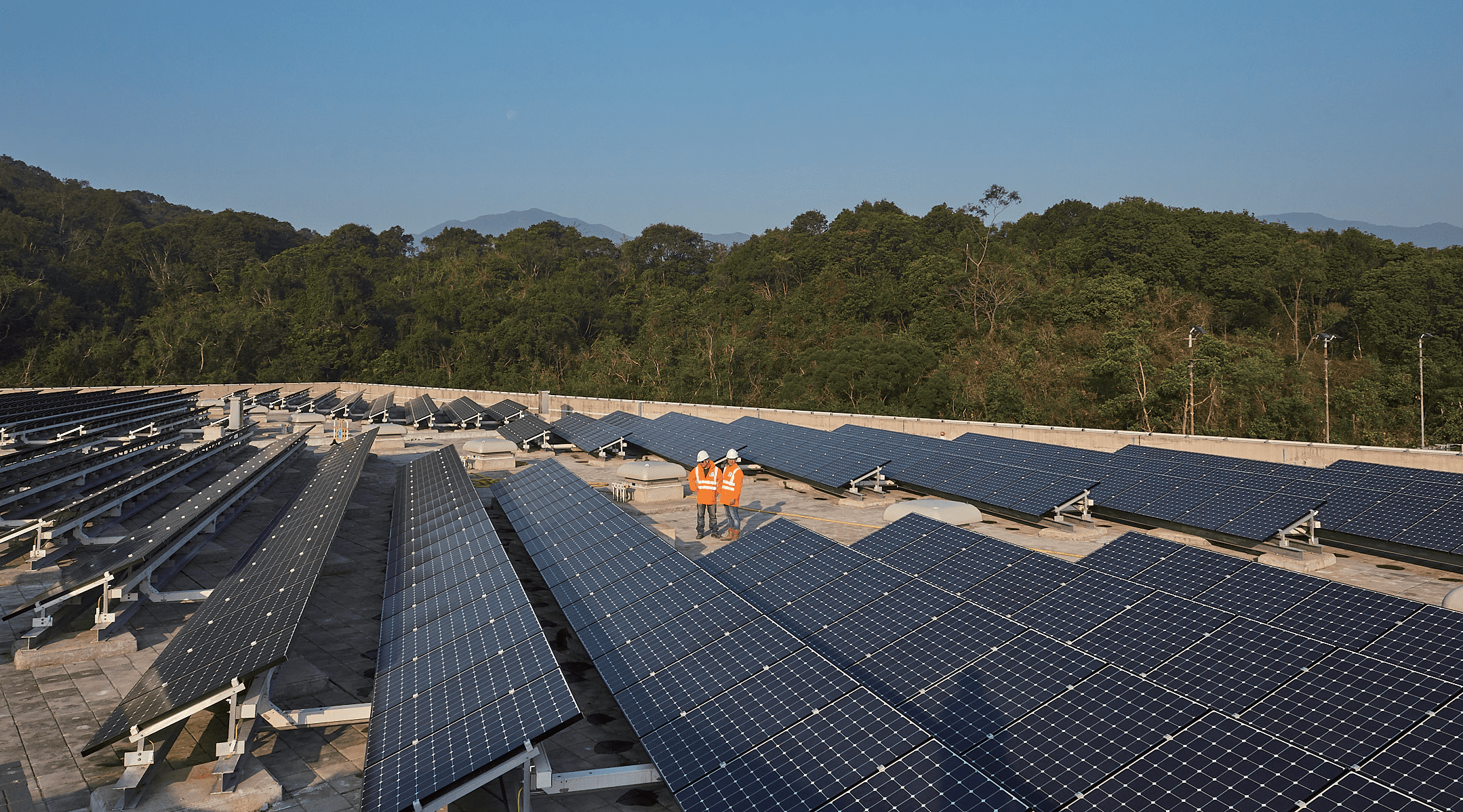

Renewable Energy Technology

The TPWTW has installed 693 solar panels, each measuring about 1.6 m². These can generate about 260,000 kilowatts of electricity annually, which is sufficient to provide about 3% of the daily energy demands for the operation of the water treatment works.