The Sha Tin Water Treatment Works (STWTW), located at Hin Keng, is the largest water treatment works in Hong Kong. Commissioned in 1964, it underwent three expansions during the 1970s and 1980s. The treatment capacity reached one million cubic metres (mcm) per day at its peak. However, after operating for over 50 years the facilities are nearing the end of their service life, with a consequent decline in efficiency and a scarcity of replacement parts. In anticipation of rising water demand from new housing developments, the WSD began preparations for the reprovisioning of the STWTW in 2015. After completion of the new South Works on the same site by 2026, it will again be the largest water treatment works in Hong Kong.

The STWTW treats raw water from five different sources, including the Dongjiang, Plover Cove Reservoir, High Island Reservoir, Lower Shing Mun Reservoir and several catchment intakes. Water from these sources will be used depending on varying conditions, with the treatment process adjusted accordingly, making the operations of the STWTW challenging and complex. For instance, water would be relatively turbid during the rainy season, the treatment works will use an appropriate treatment process depending on the raw water quality. The treated water is widely distributed to Sha Tin, central Kowloon and parts of Hong Kong Island.

Design and Construction Challenges

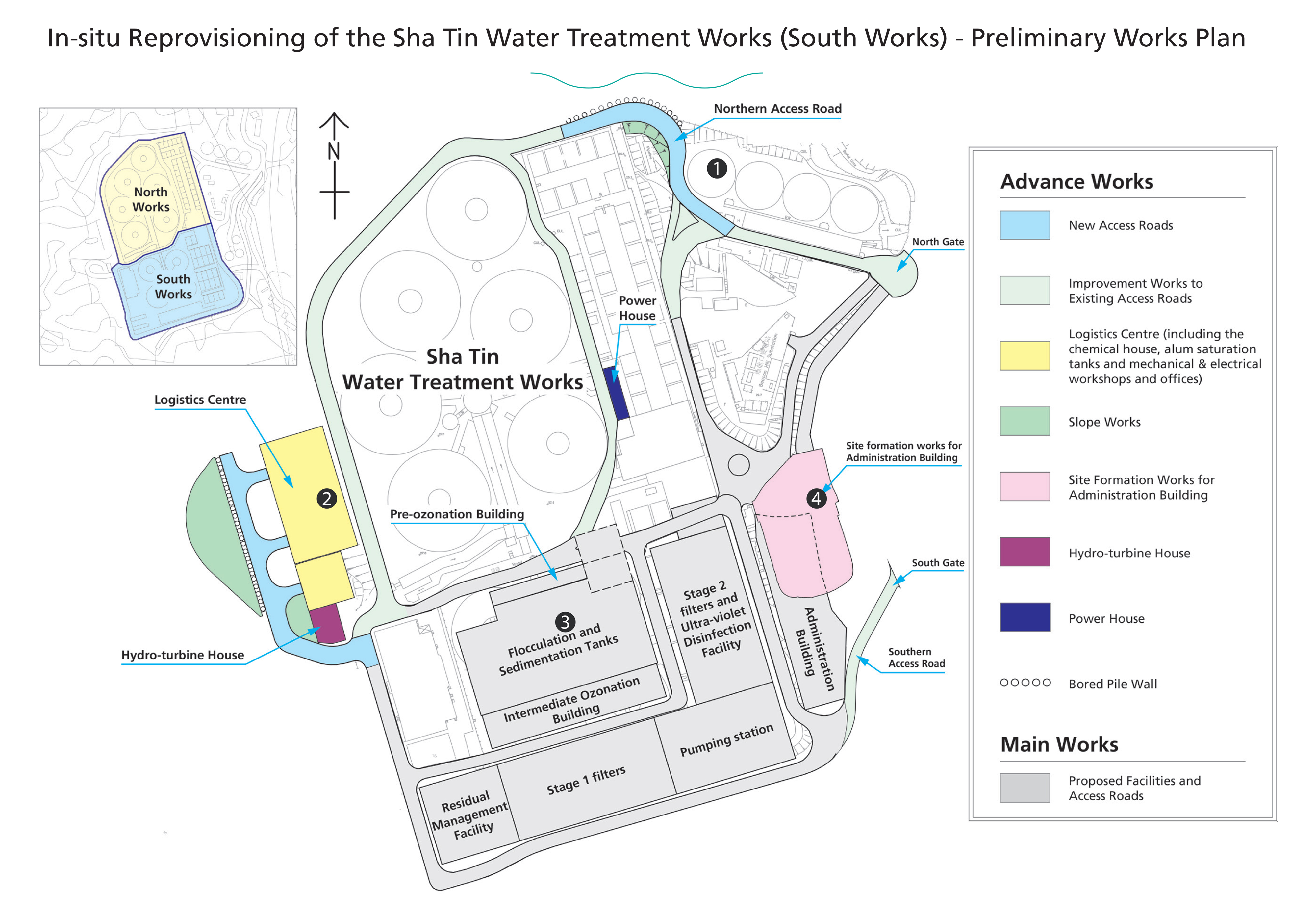

The STWTW site is divided into two sections, the South Works and the North Works. Built first and commissioning in 1964, the South Works was accorded with priority for redevelopment. Taking into account the site area and the fully developed water supply network, reprovisioning of the South Works on its existing site is the most appropriate and effective redevelopment option. The entire project involves the planning and reprovisioning of all the facilities shared by the North and South Works, target daily treatment capacity of the South Works increased from its current 364,000 cubic metres (m³) to 550,000 m³, an increase of over 50%.

During the construction period, the North Works will keep operation to ensure adequate fresh water supply to the joint water supply zone. All construction and site works must be fully planned during the reprovisioning of the South Works. In particular, it is crucial to consider the constraints of the site’s layout and continuing operational requirements, particularly when the original plant site has already been fully utilised. The design and construction arrangements must account for these factors:

In-situ Reprovisioning of the Sha Tin Water Treatment Works (South Works) - Preliminary Works Plan

Ensuring Normal Operations for the North Works

1 The original access road to the STWTW passes through the South Works before reaching the North Works. To ensure the North Works continues to operate normally during the South Works’ reprovisioning, a new road leading to the North Works will be built at the site’s northeast corner.

2 Prior to the demolition of the chemical house at the southern end of the current site, a new logistics centre for the treatment works will be built and opened to maintain the North Works operations.

Local Adaptation Design and Waste Reduction

3 The new South Works’ flocculation tank, sedimentation tank and ozone building are designed to fit within the original four circular clarifiers. The original circular clarifiers are located about ten metres below ground level, allowing the existing topography to be used and avoiding extensive excavation and unnecessary backfilling.

4 The original South Works’ administration and laboratory building comprises four levels and a basement. It will be rebuilt within the three original wash water recovery tanks to reduce excavation when constructing the new basement.

Innovation and Sustainable Development

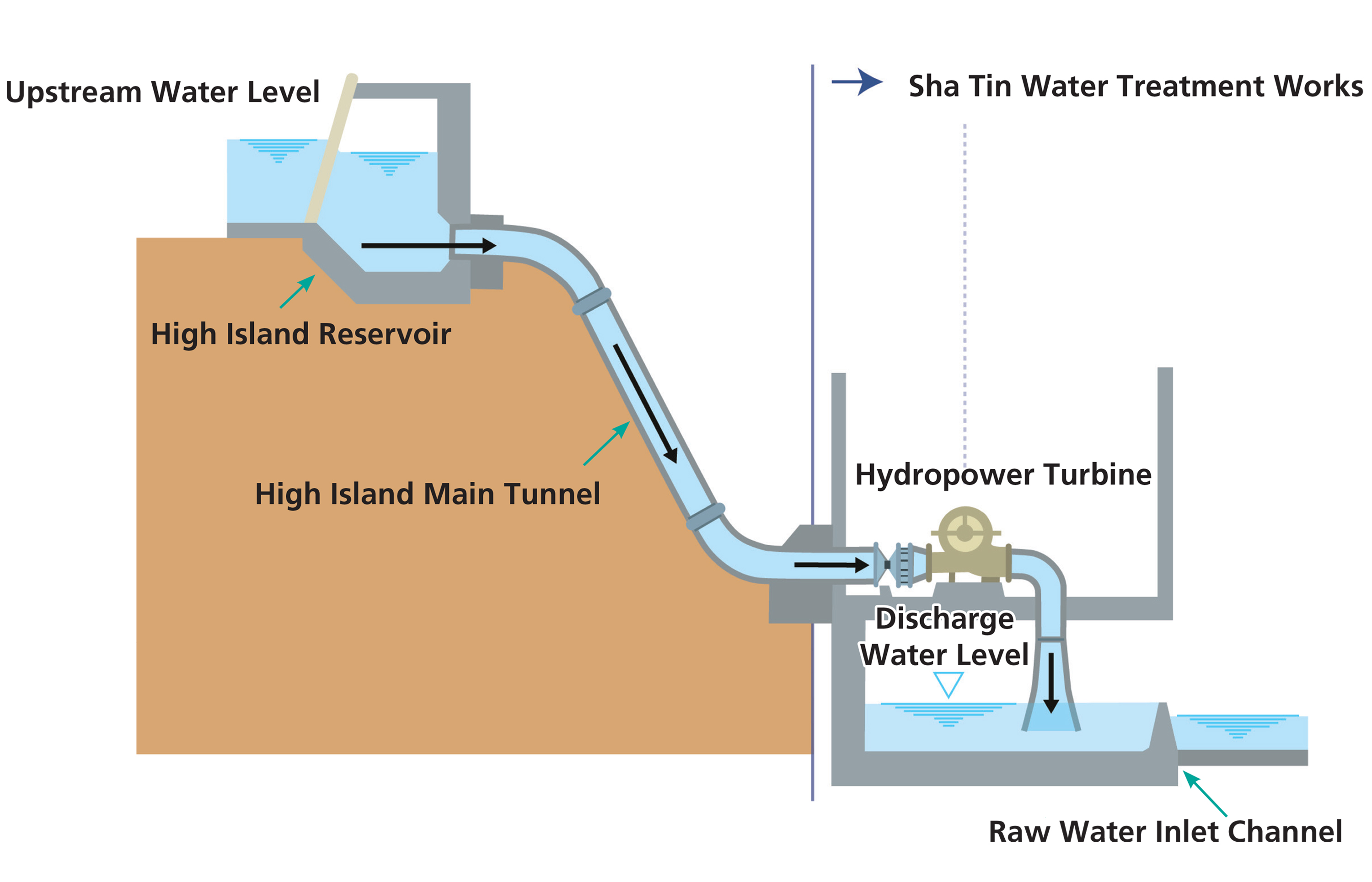

Hydropower Generation

The STWTW is the second water treatment works in Hong Kong, after the Tuen Mun Water Treatment Works, to be equipped with a hydro-turbine for electricity generation. Due to the topographical level difference between High Island Reservoir and the STWTW, the hydropower station uses the raw water flowing down from High Island Reservoir to drive a generator, which converts surplus potential energy into electricity that can be fed into the power supply network of the water treatment works. This provides electricity for the plant’s logistics centre, thus effectively use of renewable energy and reduce carbon emissions.

Diagram of the principles of hydropower plant generation

Solar Power System

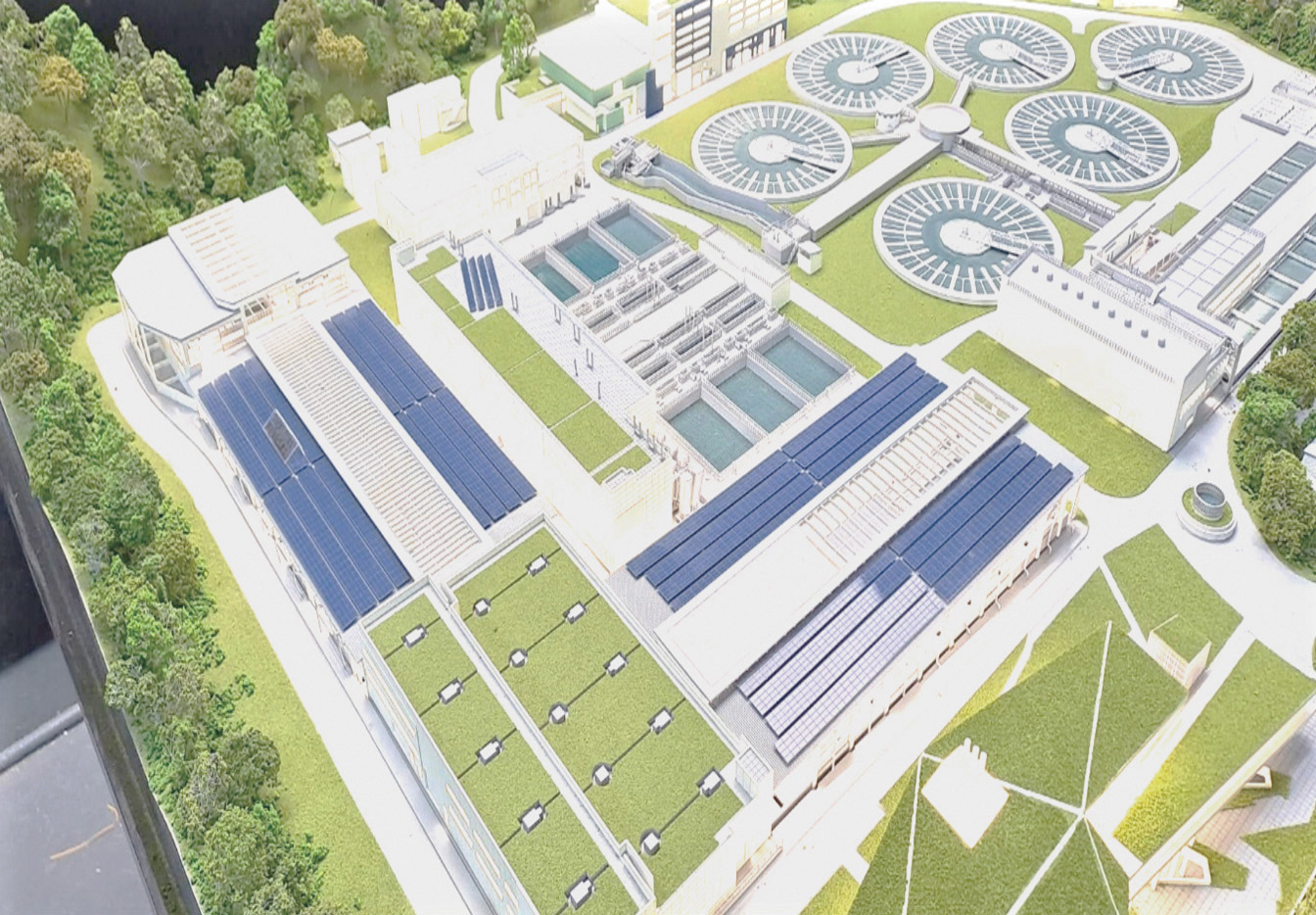

Solar photovoltaic (PV) panels are installed at the ozone building’s rooftop and on the roof of the filtration tank to generate electricity for the water treatment works facilities. The WSD will also explore the possibility of installing solar power systems to the rooftops of the remaining water treatment facilities to maximise energy efficiency.

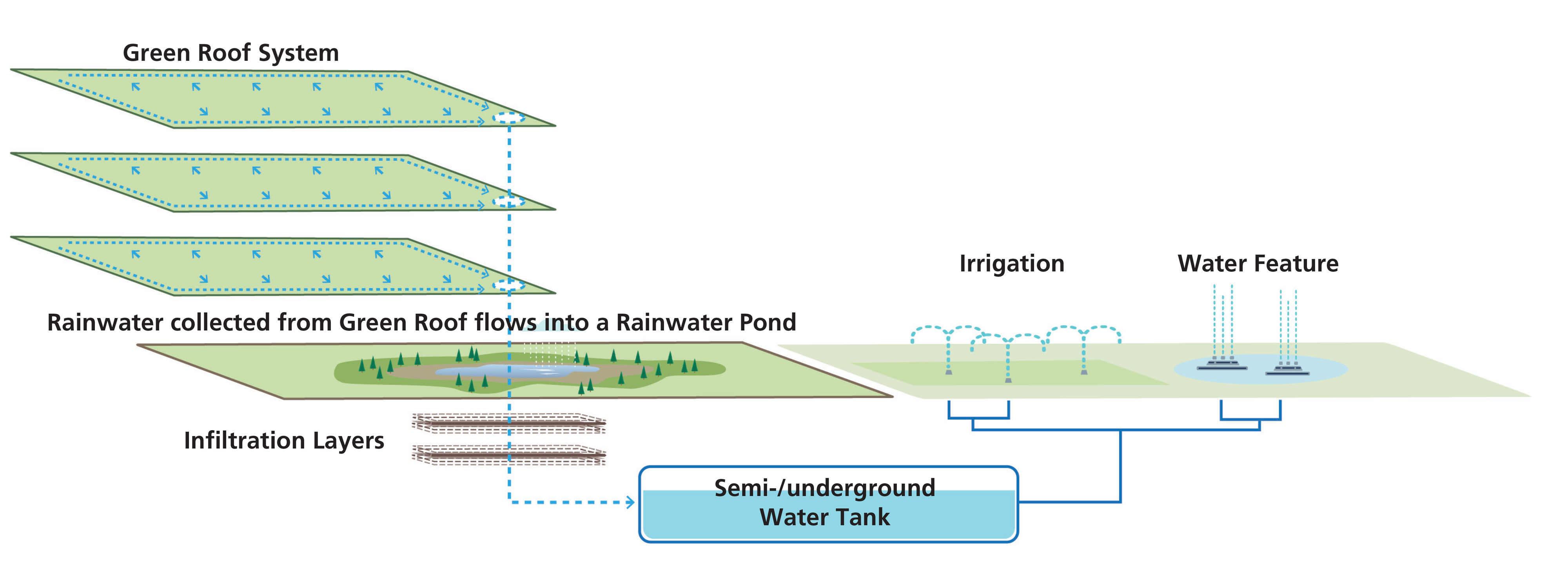

Green Roof and Rainwater Harvesting System

A rainwater harvesting system is installed in the water treatment works’ administration building. The rainwater collected from these green roofs is filtered by activated carbon and disinfected by ultraviolet (UV) light stored in a water storage tank and used for irrigation and the site’s water features. The tested water samples will be recovered through the recycling system, such that “zero effluent discharge” can be achieved for the entire water treatment process.

Diagram of the green roof and rainwater harvesting system

Old and New Water Treatment Technologies

The newly reprovisioned water treatment works will increase the efficiency and capacity of water treatment by replacing the current conventional 60 year-old technology with advanced water treatment processes and technology, which will use less land space and will enhance the reliability of water supply to meet the rising demand for fresh water and increasingly stringent water quality standards.

Clarification

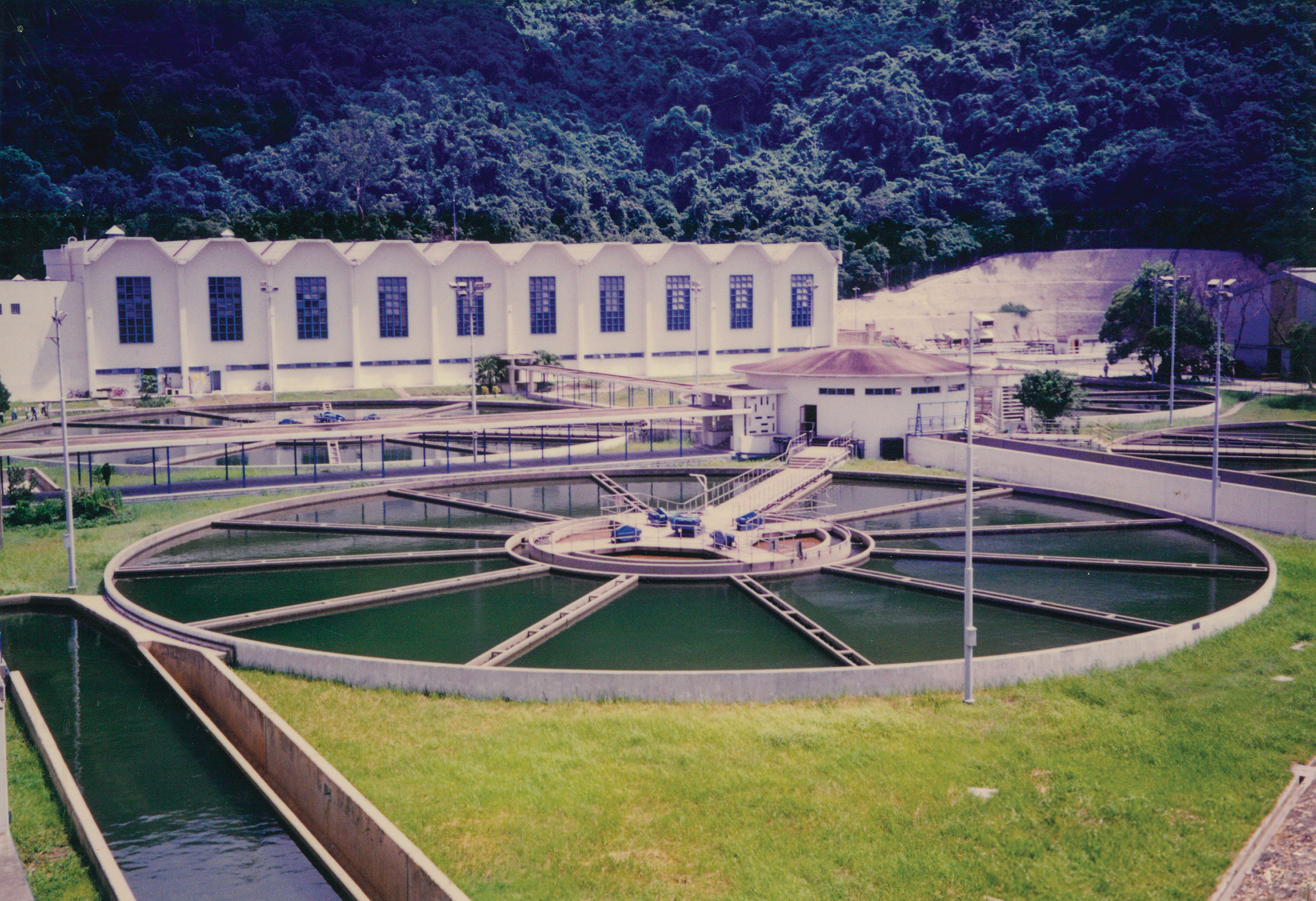

The circular clarifiers are the signature feature of the STWTW. The South Works originally had four clarifiers, each was approximately 49 metres in diameter and 7.6 metres deep.

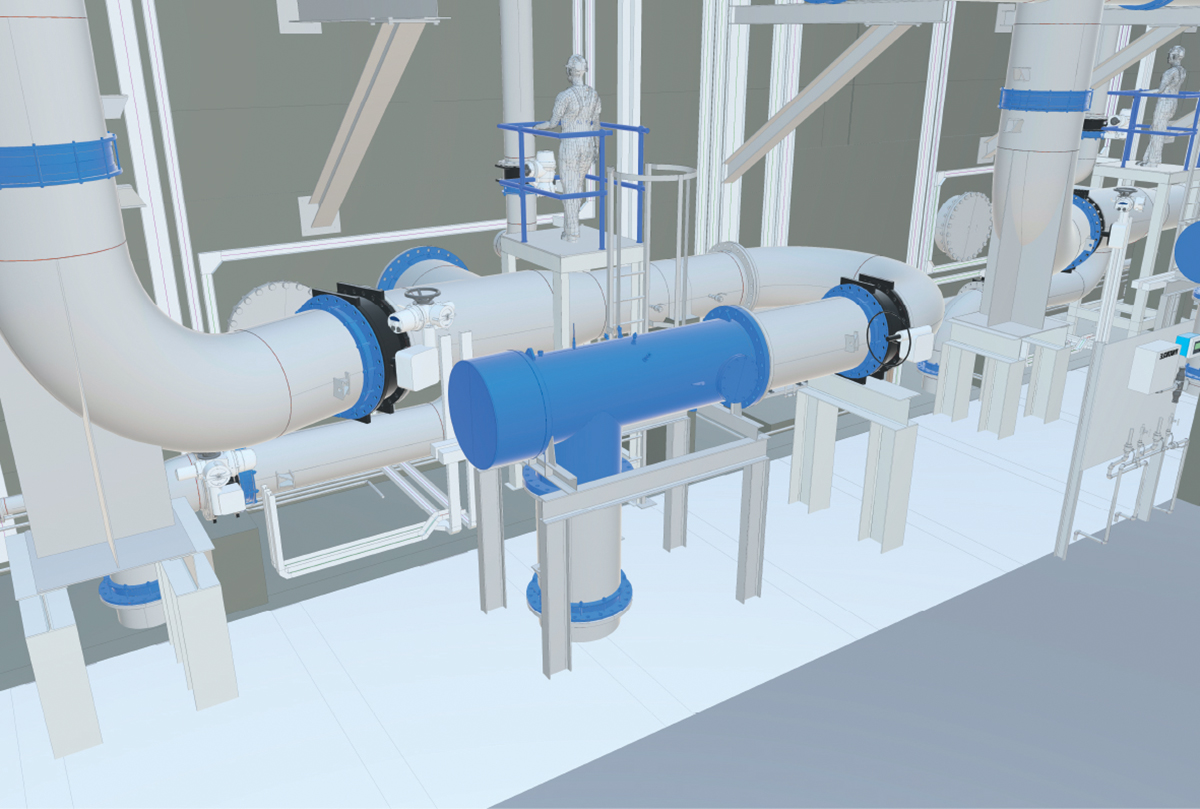

The new flocculation and sedimentation tanks utilise the advanced technology of high rate sedimentation to improve its efficiency. It significantly reduces the footprint of the treatment process unit. It will now treat 550,000 m³ of raw water per day.

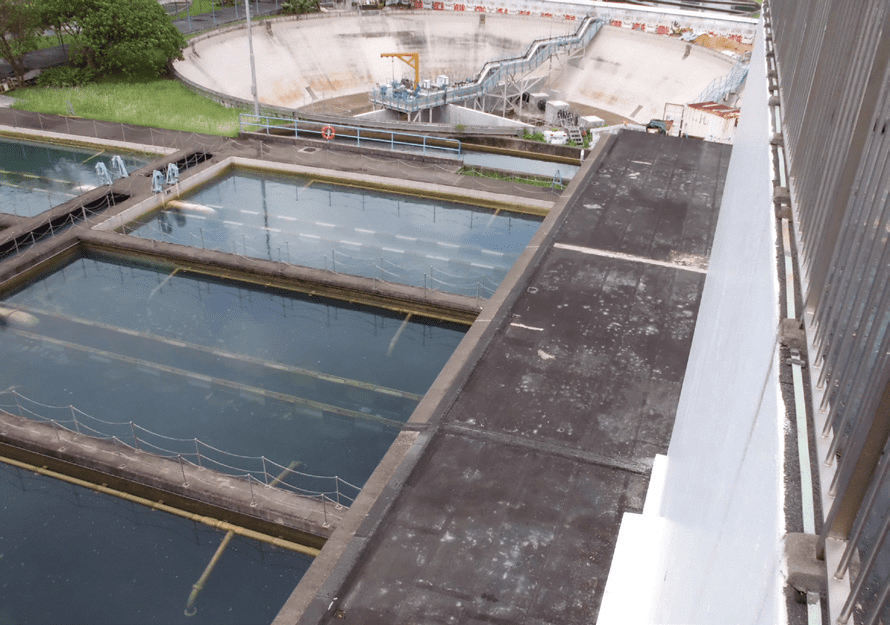

Filtration

The South Works has 22 rectangular rapid gravity filtration tanks, each with an area of 181.14 m² and a filtration rate of 8.365 metres per hour. The tanks are lined with two types of filtration media, quartz sand and anthracite, to eliminate fine suspended particles residues in the clarified water.

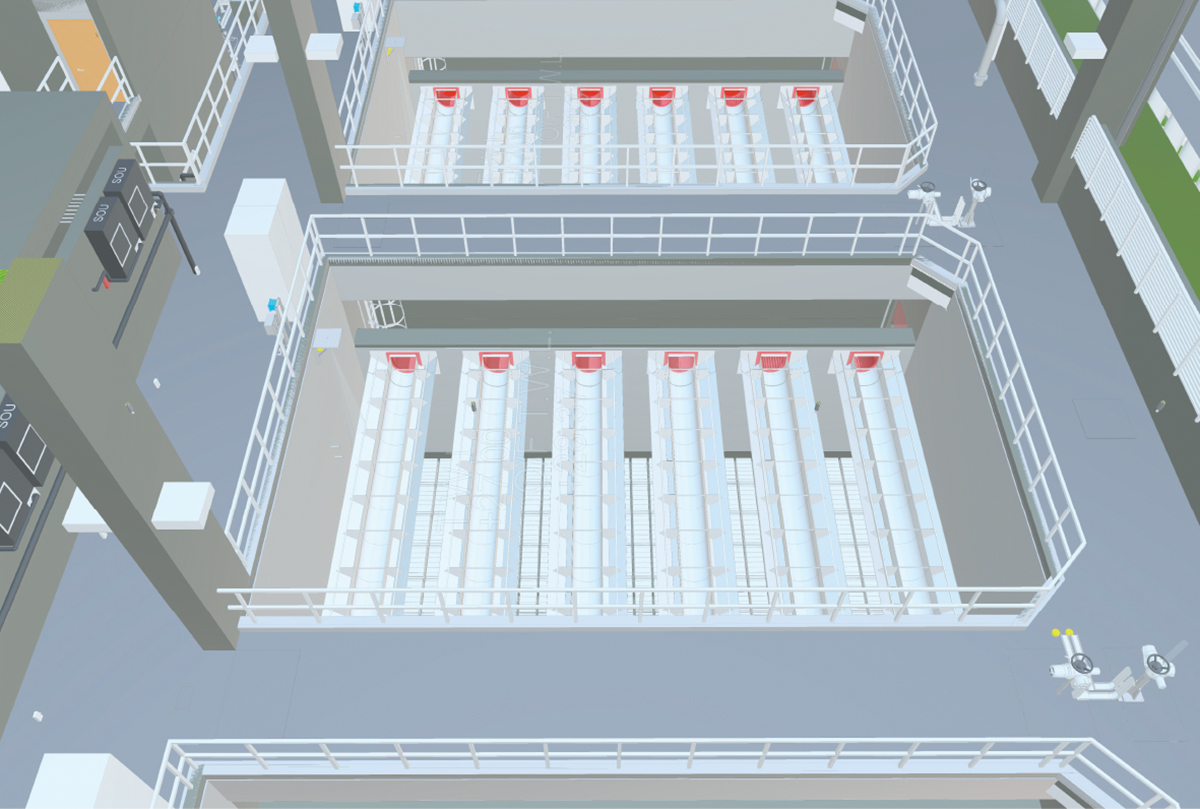

The refurbished water treatment works will feature a two-stage filtration to provide biological and granular deep bed filters. This process includes biological removal of ammonia nitrogen, which helps to reduce the amount of chlorine applied. Physical interception is subsequently employed to remove residual particles and purifies the water after biological treatment.

Water Disinfection

Chlorine is used for oxidation and disinfection at the South Works. The water treatment works has a chlorine storage room where chlorine drums containing liquid chlorine are stored. A chlorine evaporator raises the temperature of the liquid chlorine to a gaseous state and then delivers it to the water chlorination units.

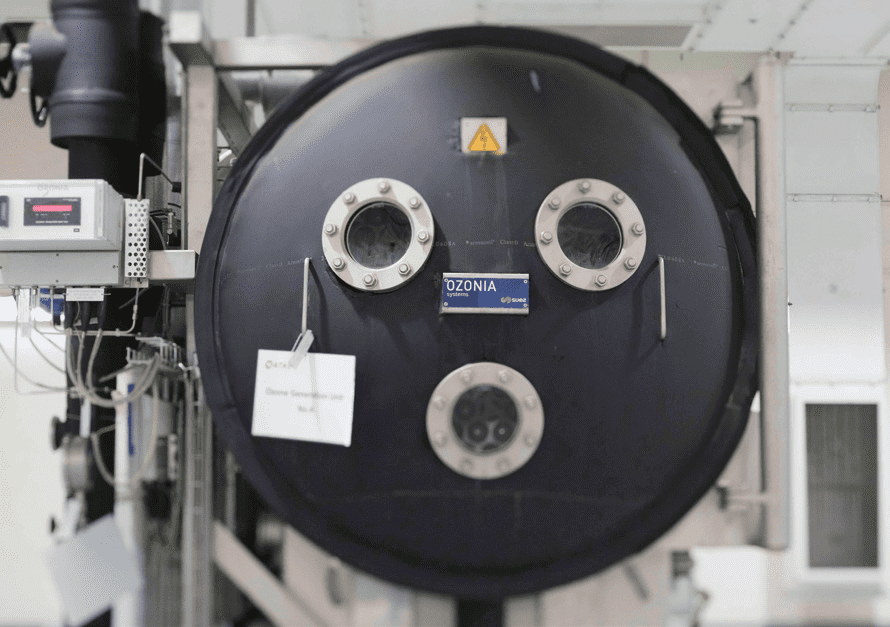

The ozone building will provide two-stage ozonation. Ozone is a potent disinfectant and oxidizer with a fast chemical reaction. It is effective in eliminating impurities that cause odour, and removing metals such as iron and manganese that cause a yellowish hue in the water. It also eradicates microorganisms and inhibits the growth of algae. Since ozone is produced on site, it is a safer alternative than transporting chlorine gas.

The South Works of STWTW will be one of the water treatment plants using UV disinfection in water treatment processes. The UV disinfection facility is installed downstream of the filters. The filtration process can effectively kill 99.99% of pathogens, viruses and microorganisms, while reducing their activity and greatly enhancing the effectiveness of water filtration.

The Optimum Time to Start Reprovisioning

"Each individual team member is essential and valuable. Only by thoroughly applying every single person’s knowledge, understanding and relevant experience can a task be fully accomplished - no matter the changing situations, considerable difficulties or unpredictable challenges that arise,” Ir Horace NG Chou-keen, Senior Engineer of the New Works Branch, shares his experience of managing the STWTW reprovisioning project and the importance of a good work culture and ethics.

It was previously mentioned that the reprovisioning of STWTW is essential, and it was of utmost importance to ensure that the existing operation of the North Works and the associated water supply would be maintained. In fact, the planning for the reprovisioning of STWTW started some years earlier. It involved an overall review on the demand and supply of the entire joint water zone. This led to the earlier expansion of the Tai Po Water Treatment Works. When it came to the detailed design and construction stages for the new South Works, more robust and cautious considerations and assessment of the practical operations were required. This aims to achieve the seamless water supply transition from the existing North Works to the supply network of the South Works.

Ir NG explained that before demolition of the South Works structures, the common facilities of both the South and North Works must be isolated first. “As a comparison, the operation was simply like splitting the organs of conjoined twins. Among the shared facilities are five 1.5-metre diameter trunk water mains which are vital for transferring filtered water to the service reservoirs and water supply network. The STWTW serves a population of over two million people, so it is estimated that the supply of each trunk mains potentially affects the daily lives of households in a couple of hundreds thousands. This especially demonstrates how challenging and critical the scale of the diversion works would be implemented. The suspension, cutting and reconnection of water mains on such a large scale involves a series of comprehensive procedures, including: suspension of the STWTW pump operation, emptying the associated sections of water mains, cutting and welding of the new connecting pipe sections, and restarting of water pumps, etc. These procedures normally take several hours to complete.

The hours-long diversion operation at the site is only the tip of the iceberg, with the whole planning, preparation and coordination ahead of the diversion works being much more intensive. “To suspend the operation of the water treatment works for a few hours actually entails a series of detailed working procedures and a checklist to be followed the weeks before starting. We then had to coordinate with other water treatment works to temporarily increase their water supply, adjust the network of the water supply zones to cope with the situation, and fill up the potentially affected service reservoirs in advance to meet basic water supply demand during the shutdown. A fall-back was also arranged to temporarily supply water using water wagons if necessary. The entire deployment was so tight, even one mistake could lead to the failure of the whole operation with serious consequences,” said Ir NG. With these considerations in mind and the careful implementation of each step by colleagues from different divisions, the focus quickly shifted to the final arrangements with frontline staff during the optimum work hours to minimise the impact to the public during the morning, afternoon and evening peak periods of water usage.

Ir NG recalled a potentially serious incident on Christmas Eve when the scheduled water suspension and diversion schedule were about to begin. While waiting for the operation to start and with dozens of staff from different divisions and engineering teams in place, the monitoring staff identified an abnormal drop in water pressure in the supply network. This was unexpected and immediately put stress on the entire plan and the capability of the work teams.

The problem implied a possible seepage or leakage in the water mains or connection points with a potential bursting risk. The original scheduled diversion scheme was immediately put on hold to implement the emergency plan to investigate the location of the suspected leak. This was achieved by comparing and analysing the pressure data while adjusting the water pump discharge, as well as the opening and closing of valves to trace and narrow down the potential location of the problematic section. It was followed by careful observation and excavation on site to confirm the location of the problem.

Ir NG outlines how they solved the issue, "We made use of the instant messaging group we had earlier set-up when planning the diversion works. Colleagues were then able to keep in close contact, as well as to disseminate the real-time information, such as water pressure, water levels, valve opening or closing conditions, and formulate action plan for different scenarios using the experience and knowledge of team members. You could feel the dedication of the whole team, all working closely to solve the problem and find the best solution of benefit to all. Suddenly, without any of us noticing, it was midnight on Christmas Eve! Collectively the group studied plans for every possible scenario and agreed that the repair, cutting and diversion works could still all be done if the leak could be identified before 2a.m. This would allow the work to be completed in one go and by the start of the morning peak demand period at around 6.30a.m. "Although the leak was identified till at 3a.m., the main leakage was fortunately controllable. The team immediately stabilised the leaking pipe and maintained an adequate supply on the following day, while closely monitoring the situation and scheduling to complete the repair works on the following night when the water consumption is at its lowest. Despite a stressful night to locate and fix the leak, the spirit of the whole team remained high. During the Christmas holidays, the team continued reporting through the instant messaging group to ensure preparations remained on track.

Neighbours overlooking STWTW soon noticed the unusually brightly-lit water treatment works at night during the Christmas holidays and made telephone enquiries. Fortunately, the team were proud, but relaxed to advise that the necessary diversion works were successfully completed without disturbing everyone’s Christmas celebrations.

Continuous Learning and Problem Solving Professionalism

There are 20 water treatment plants in Hong Kong and their useful life-span runs for more than 50 years. Opportunities to participate in the construction of new water treatment works are therefore rare. Ir NG, who majored in civil engineering at the university, had previously worked in the Highways Department and the Drainage Services Department before joining the WSD. Although there are similarities in the management of engineering projects between different departments, there are also significant differences in the required professional knowledge. For example, pipe networks look similar, however the discharge of drainage and sewage is mainly designed to fall by gravity without pressurisation, whereas the supply of treated water is achieved with pressure. Furthermore, the filtration and treatment of sewage and drinking water are very different in terms of purposes, technologies deployed and the processes and chemicals involved. As for the construction of roads, bridges and tunnels, these obviously require professional knowledge distinctly different from water services.

Ir NG joked that his water treatment knowledge still remained at the theory level, similar to university study without much practice. So, for his new role, he worked sleepless nights familiarising himself with project details by studying office files, emails, past records, documents, design calculations and standards, operation and maintenance manuals, and any relevant source of knowledge after first joining the department. He also took every opportunity to share and discuss with colleagues from other divisions and teams and through working meetings to grasp useful work knowledge and information.

Ir NG explains that having soft skills in project management is important and that, "In this era of artificial intelligence, when technology and machinery are gradually replacing many human tasks, the value of humans often lies in the ability to respond and perform, even under ever-changing and emergency situations by making decisive decisions using optimum solutions.” He emphasised that, “The key to do this surely lies in a thorough understanding of the underlying theories, principles and content of each task. It is only when one has the relevant knowledge and actively learns from the experience of people in different positions that a task can be truly and well delivered; in particular, to achieve our fundamental mission of serving the public. You need to have the professionalism, attitude and ethics to do the right thing in engineering, if not all professions. I believe that when you work whole-heartedly and honestly without making shortcuts or bargaining, your colleagues and working partners, such as consultants and contractors, will show the same respect on projects and together try to achieve something great.”