In response to the extreme impact of climate change on local yields, the WSD is developing desalination as a strategic water resource and has commenced construction of the first stage of the Tseung Kwan O Desalination Plant.

The principle of converting seawater into potable fresh water is the removal of salt and impurities. Despite not using rainwater or river water as the source, desalination is still considered to be a filtration technology. As seawater makes up 97.5% of the world's total water bodies, its utilisation means desalination is one of the few water resources that remains unaffected by climate change. To enhance the resilience of Hong Kong's water supply, the first stage of the Tseung Kwan O Desalination Plant will be commissioned in 2023.

As early as 1975, Hong Kong had built at that time the world's largest desalination plant at Lok On Pai. Run on petroleum, it employed the "Multi-Stage Flash Distillation" technology, using a distillation principle similar to those of a distilled coffee machine. However, the technology was very energy-consuming and expensive, eventually it was only used in times of low rainfall. In the 1980s, the global oil crisis led to a significant increase in the cost of desalination and the government suspended its service in 1982. Today, desalination technology has become more advanced. In addition to the conventional thermal method, the world's most advanced reverse osmosis (RO) technology will be used at the Tseung Kwan O Desalination Plant.

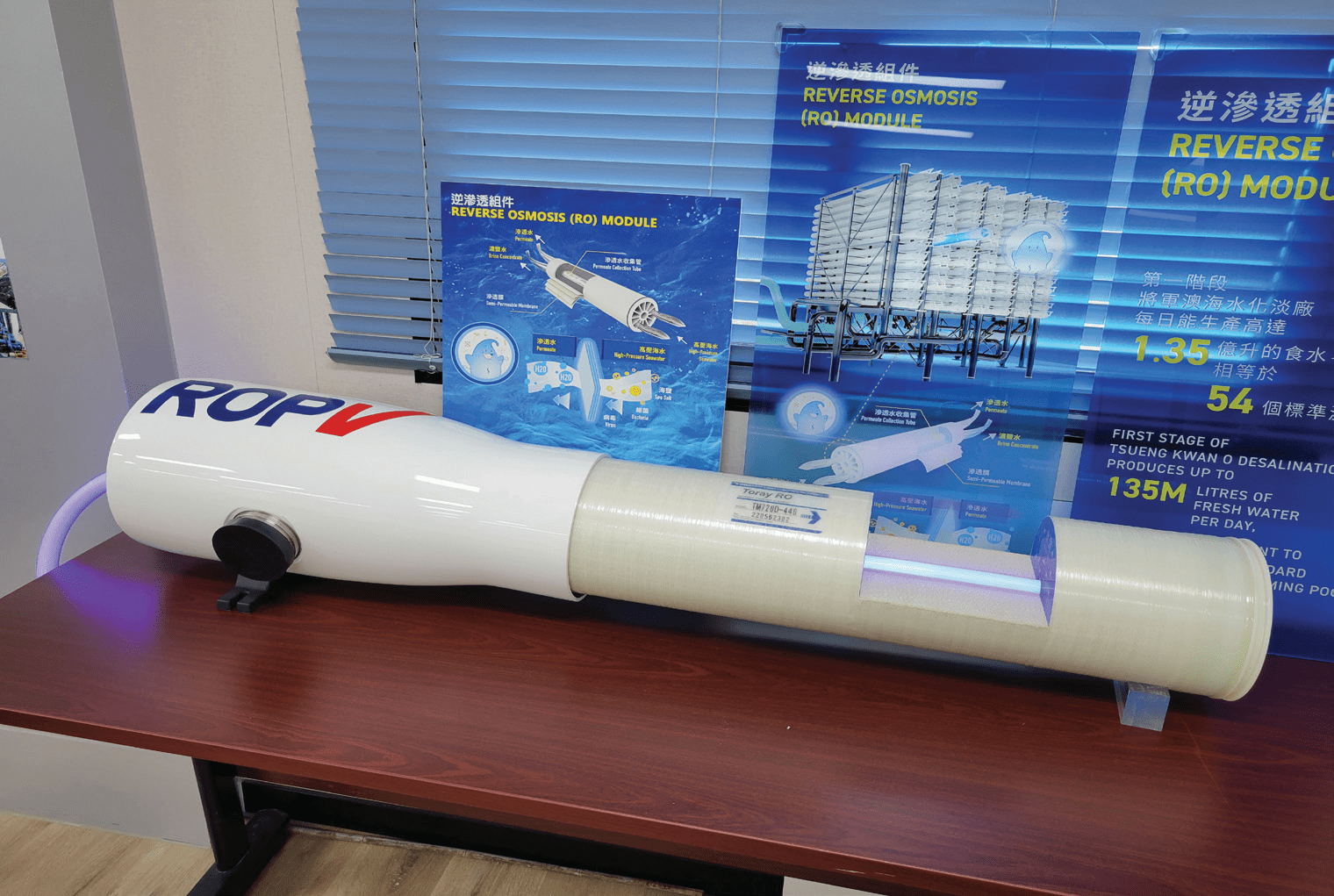

RO technology uses a special filter membrane to produce fresh water and compared to conventional thermal methods, RO uses less energy and has a higher fresh water recovery rate. For every tonne of fresh water produced, only 2.5 to 3.2 tonnes of seawater is required. The cost of desalination has been reduced due to the widespread use of new technologies. At present, the unit cost of producing drinking water at the Tseung Kwan O Desalination Plant is about HK$13 per cubic metre (m³), which includes the initial construction costs, operation costs, water distribution, customer services expenses etc. This is comparable to the unit cost of the equivalent production overseas. However, it is still 30% higher than the cost of drinking water produced using Dongjiang water and from local yields.

Characteristics of the Semi-permeable Membrane

Although RO technology uses semi-permeable membranes to block impurities, and appears similar to filtration, it is more superior to conventional filtration methods. In general, filtration uses a porous medium that blocks large impurities, and allows water molecules and other water-soluble substances to pass through. For this reason, there is little difference in the chemical composition of raw water compared to filtered water.

The semi-permeable membrane used in RO has extremely small pores with a diameter of just 0.1 nanometre (i.e. roughly one millionth the size of a hair). This allows only water molecules and trace mineral ions to pass through, thereby blocking salt, impurities and other harmful substances from seawater.

The Reverse Osmosis Principle

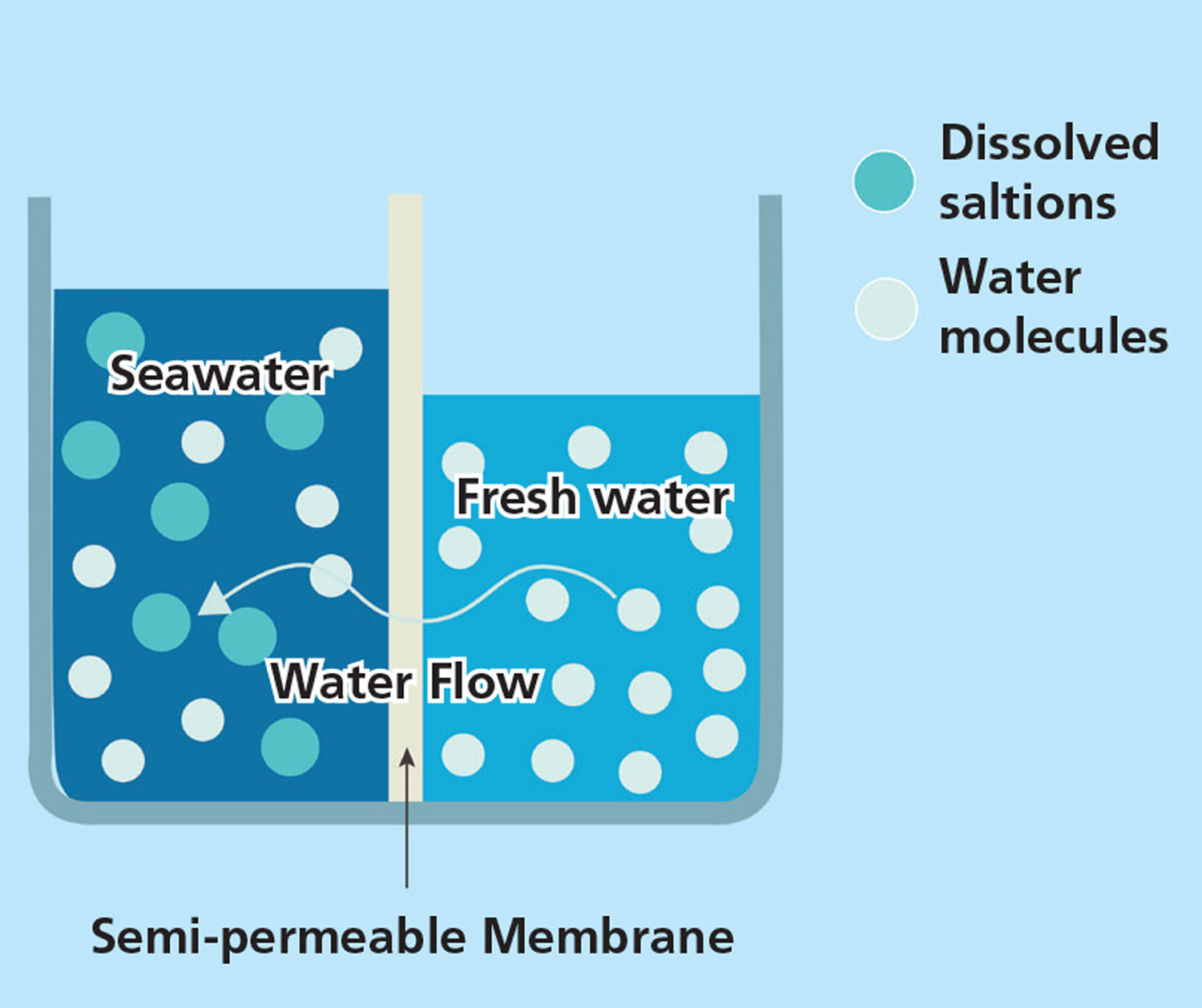

Membrane desalination applies the mechanism of interception using a semi-permeable membrane to remove impurities, but the principle at play is osmosis.

When two liquids of different concentrations are separated by a semi-permeable membrane, water molecules flow from a less concentrated solution to a more concentrated solution until an equilibrium is reached. This phenomenon is known as osmosis.

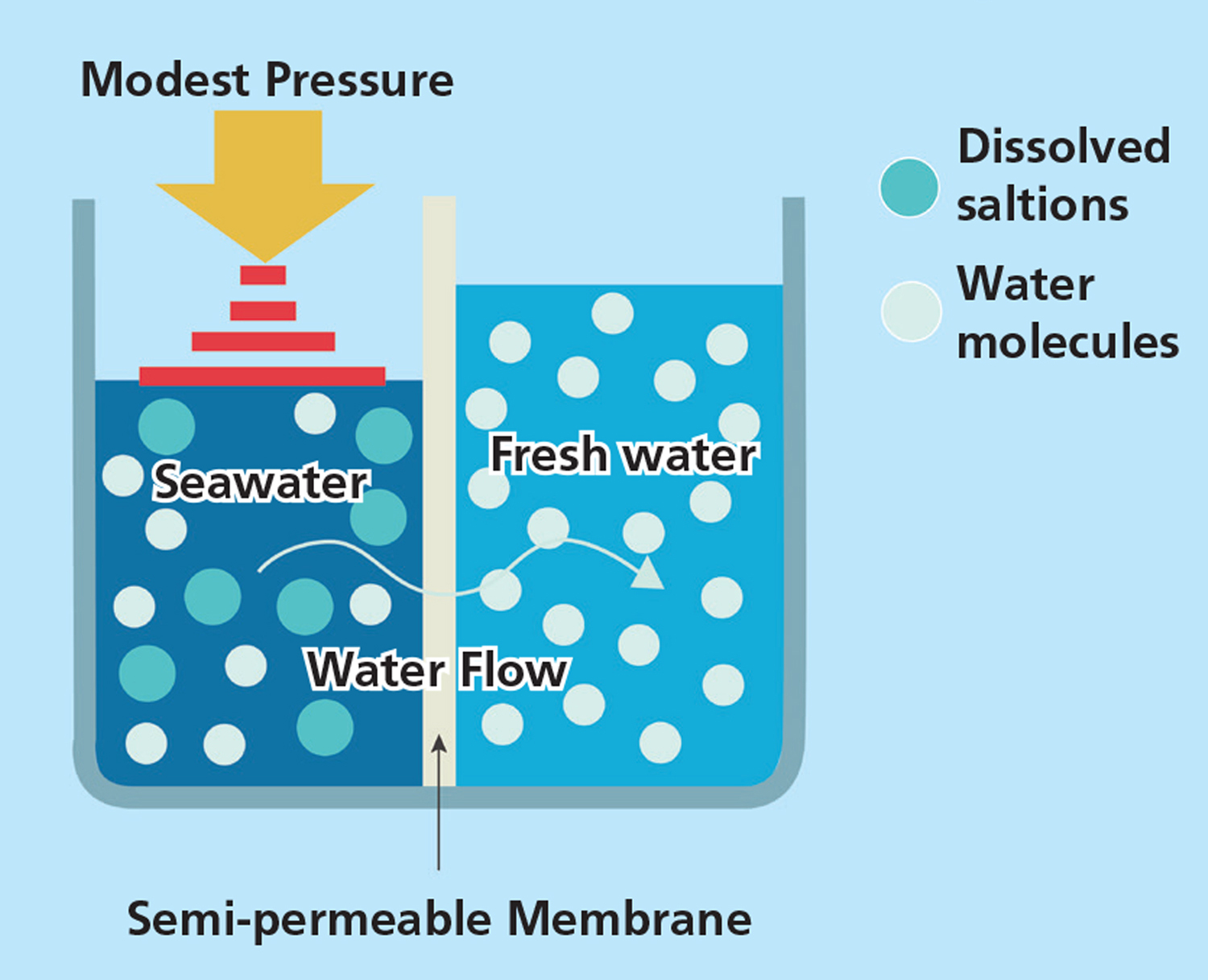

RO involves reversing the flow of water by applying pressure on the more concentrated solution. As long as the pressure is greater than the osmotic pressure, water molecules are forced to flow through the semi-permeable membrane to the less concentrated solution, hence removing salt and impurities.

The Tseung Kwan O Desalination Plant

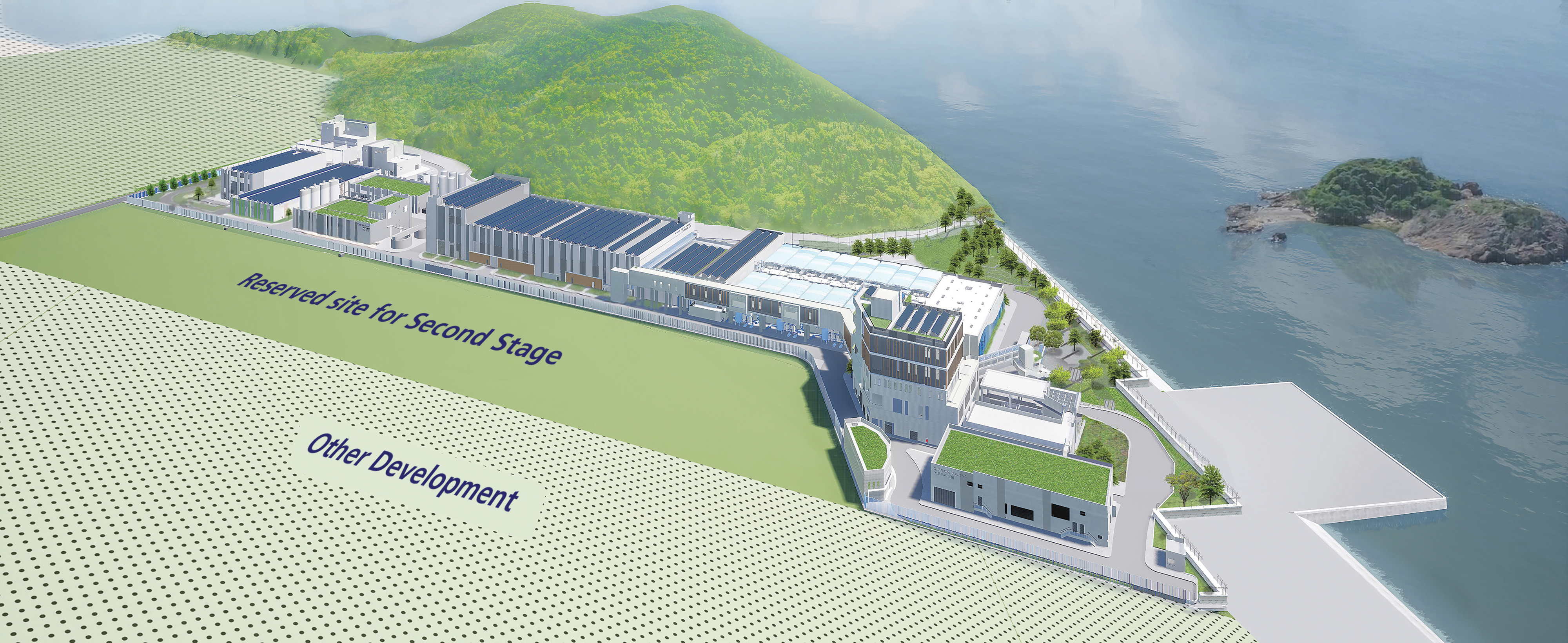

The Tseung Kwan O Desalination Plant is located in Tseung Kwan O Area 137, covering an area of eight hectares. The area is suitable in which to construct the desalination plant as it is adjacent to the WSD’s existing water supply network and the water quality of nearby seawater is less affected by sediments in the Pearl River Delta. The first stage of the Tseung Kwan O Desalination Plant will be able to produce 135,000 m³ of fresh water per day. This will increase to 270,000 m³ per day after expansion, equivalent to 5% to 10% of Hong Kong's fresh water consumption.

As the Tseung Kwan O Desalination Plant is located close to Joss House Bay and Clearwater Bay Country Park, the design and construction of the plant incorporates sustainable environmental concepts to blend-in with the surrounding environment. Renewable energy such as solar energy and low-energy consumption processes, rainwater harvesting for irrigation and maximising a greening area to enhance energy efficiency have been adopted. The project has been rated as a Provisional Platinum Certified Project under the Building Environmental Assessment Method (BEAM) Plus for New Buildings.

Apart from making good use of the 1,832 photovoltaic (PV) panels installed on the roof of the desalination plant, the WSD is planning to build a large-scale PV farm at the South East New Territories Landfill near the Plant. It is expected to provide a renewable energy generation capacity of up to ten megawatts upon completion.

This desalination plant has been incorporated as a new source of water supply in the WSD's water supply strategy. It is an alternative for future water infrastructure planning, particularly in remote areas close to the waterfront. The WSD is currently planning the water supply strategy for the Kau Yi Chau Artificial Islands and will carefully examine the feasibility and operational benefits of desalination plants set up on the islands.

The Tseung Kwan O Desalination Plant is the first water treatment facility in Hong Kong adopting the new pre-treatment “ActiDAFF” technology. “ActiDAFF” combines Dissolved Air Flotation (DAF) technology and filtration in the same tank, with the former being placed on top of the filter bed so that processed water can flow through the filter underneath, thereby reduce the required floor space of the desalination plant. The treatment of the seawater removes larger particles and organic matter from the water, which helps to reduce membrane fouling, thus protect and extend its service life.

Desalination Projects’ New Technology and the Future

Ir LAM Kwok-chuen, Senior Engineer, New Works Branch is enthusiastic about the new plant: "As an engineer working for over 30 years, it is exciting to be involved in the construction of the Tseung Kwan O Desalination Plant. After all, it is a mega-project that applies many new technologies. Our colleagues and the entire consultant and contractor teams are highly engaged.”

RO desalination technology is well-established overseas, but this is its first application for fresh water supply in Hong Kong. For WSD engineering team, “first time” means a process of learning, problem-solving, innovation and gaining experience.

The project has adopted the Design-Build-Operate (DBO) contract form, making the Tseung Kwan O Desalination Plant the first waterworks facility in Hong Kong to be operated by a contractor. “This arrangement is intended to bring in the experience and technology of overseas experts. WSD colleagues will work with the contractor as a team to operate the desalination plant. We hope that through cooperation and exchange, we will gain experience and promote the transfer of technology.”

Despite the importance of experience, unexpected challenges and problems always arise. One such example is the COVID-19 pandemic outbreak during the first month of this 39-month construction project. "The contractor’s team members are from Spain, Australia, the UK, etc and it takes time to apply for visas and work permits. Due to the tight construction programme, we had been looking at ways to efficiently integrate team members. With the push from the pandemic, it was pragmatic to undertake the design review of the desalination plant through electronic means, so the project adopted the Common Data Environment (CDE) as an electronic platform. All those involved in the project design review can modify the design on the same platform; this facilitates comparison and tracking of revisions, giving team members a thorough understanding of others’ design philosophy and the reasons for revisions. It also reduces the risk of errors or omissions due to too many emails,” said Ir LAM.

To speed-up progress of the project, the team has explored the use of Design for Manufacture Assembly (DfMA) during the design phase. This is a proactive design method that emphasises ease of manufacture and assembly effectiveness, to increase construction efficiency. “The Housing Department has long used prefabricated component construction, but waterworks structures are not as repetitive as public housing. Therefore, we explored whether DfMA could be adopted for electrical and mechanical works,” stated Ir LAM.

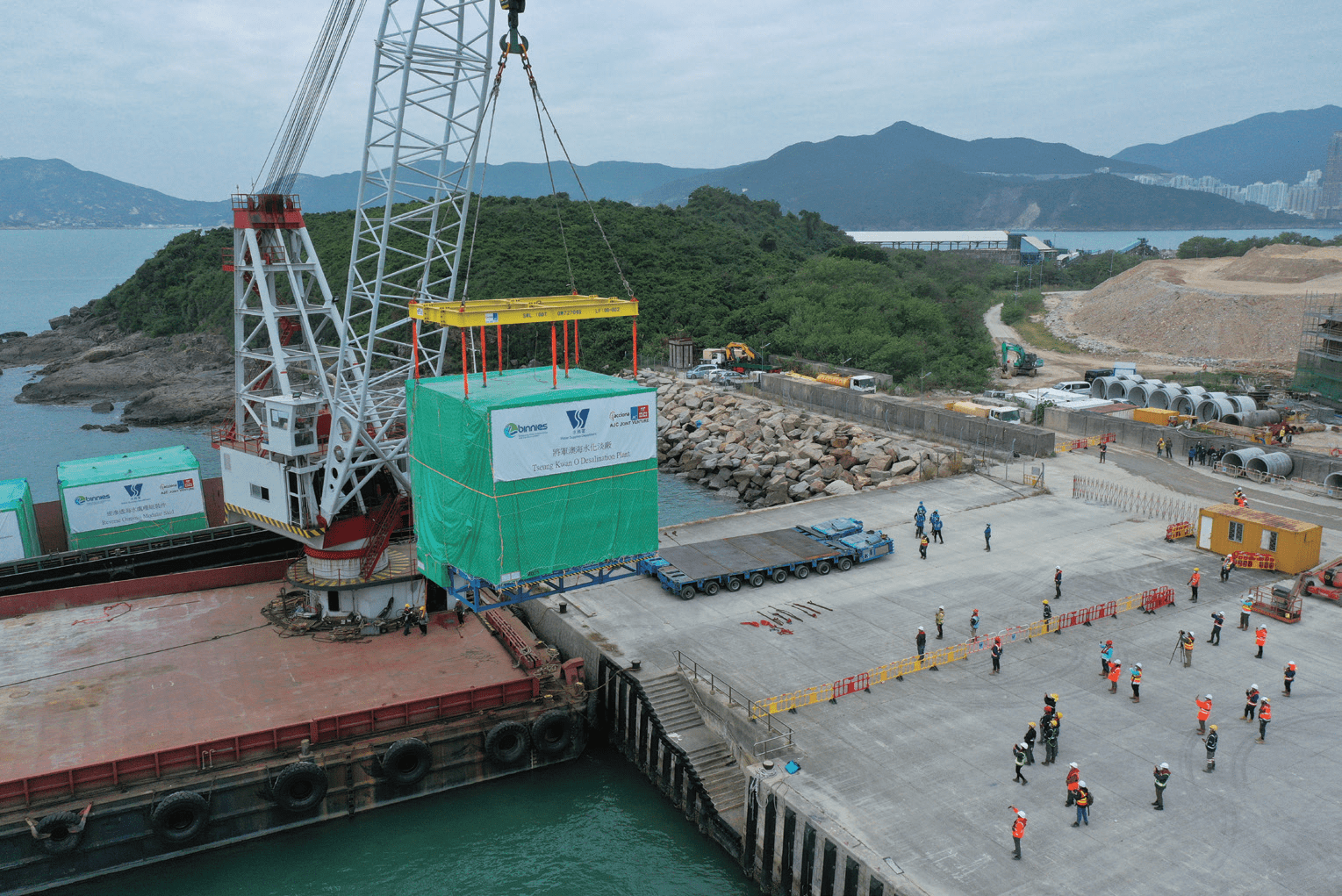

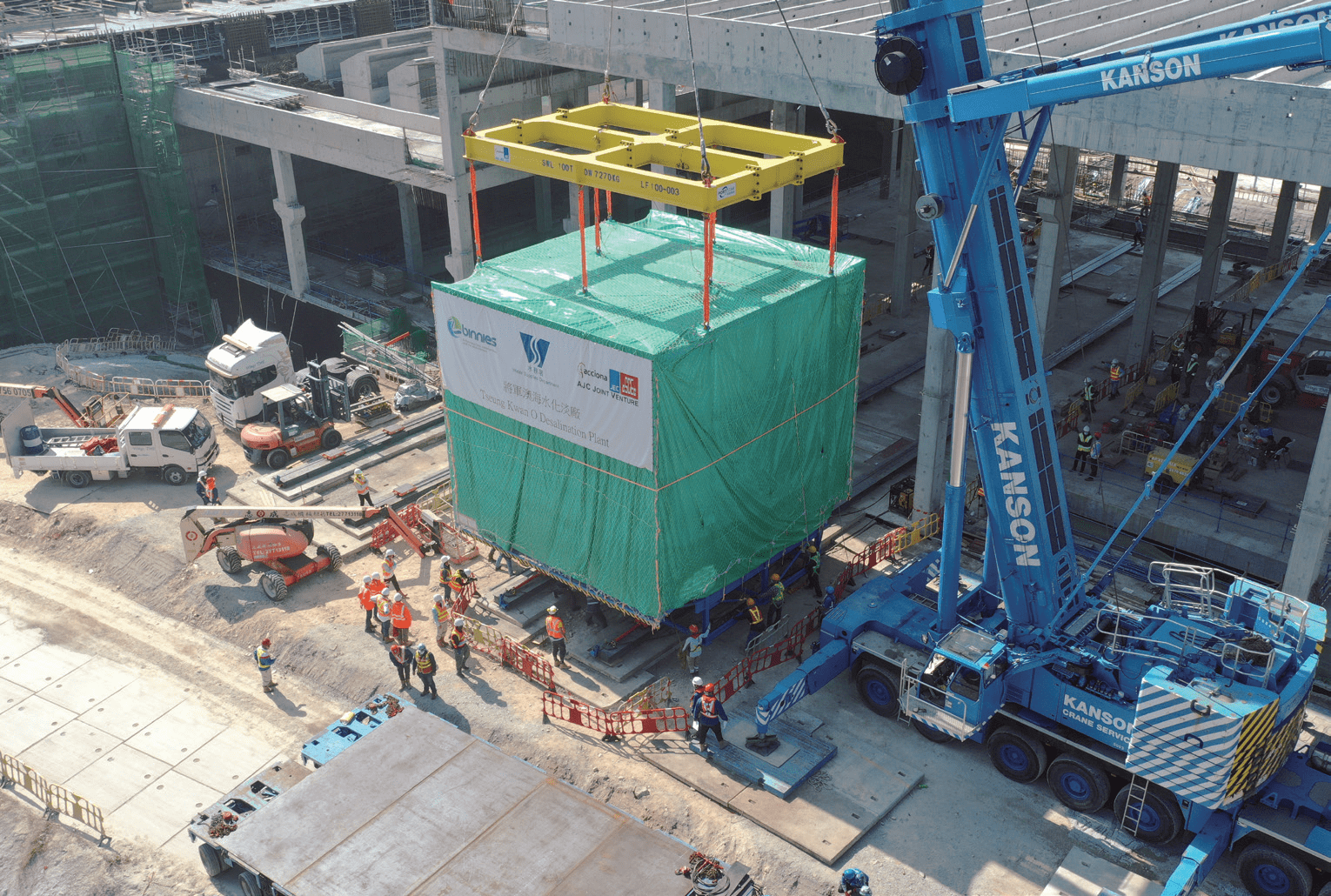

The RO process for this desalination plant will be carried out in twelve large RO racks, of which eight are involved in the primary RO process and each contains 236 pressure vessels. The remaining four RO racks are involved in the secondary RO process, each containing 28 or 84 pressure vessels. Following the conventional construction sequence, 2,336 pressure vessels would have been delivered and assembled only after the civil works of the Reverse Osmosis Building had been completed. By using DfMA, the assembly of the pressure vessels was completed in advance at a factory on the mainland, and was transported to Hong Kong by barges. Each RO rack with 236 pressure vessels is nine metres high, eight metres long and nine metres deep, and weighs approximately 90 tonnes. To suit the assembly process, the construction approach of the Reverse Osmosis Building needed modification. The building’s structural frame was constructed first to allow the accommodation of RO racks before the external wall panels were installed. Ir LAM said that such an arrangement allowed certain processes to be executed simultaneously, hence reduce the construction time and minimise the safety risks associated with working at height due to on-site assembly. “The WSD is receptive to innovative technology, particularly in promoting on-site safety and DfMA. The construction experience will be of great reference for future waterworks projects,” said Ir LAM.