Amid worsening environmental pollution and demands for better water quality in recent years, water treatment has to address a wide range of considerations. The design of water treatment processes comes in different combinations and approaches according to changing situations. In fact, water treatment is an evolving science and the technologies used in the past represented the latest research and technological advances at the time.

The Albany Filter Beds was the first water treatment facility in Hong Kong, completed in 1889 and served by water supplied from Tai Tam Reservoir. This was the first reservoir built following Mr. Chadwick's Report on improving Hong Kong’s sanitation in 1882. In addition to the dam, the Tai Tam waterworks project comprised an aqueduct, a service reservoir, and filter beds: a comprehensive water supply system in terms of quality and quantity.

Water Filtration First Acknowledged for Improvements in Hygiene

Sir Osbert CHADWICK, a British consulting engineer highlighted the significance of water treatment in his report. He considered that the use of sand filters was desirable for both old and new waterworks, “Though filtration has no appreciable chemical action on the substances in solution in water, still by removing suspended matter it is more than probable that most important improvement is effected1.”

The Albany Filter Beds adopted the slow sand filtration method, which was invented by the British engineer James SIMPSON in 1829. Typically, the slow sand filtration bed is constructed from reinforced concrete and is overlaid with a filter medium containing three layers of fine sand, gravel and coarse gravel. This arrangement permits the raw water to pass slowly through the sand and gravel to the bottom of the tank, thereby purifying the water. This group of six filter beds, built into a hillside above Central, was recommended as a tourist attraction in The Hong Kong Guide of 1893 and frequently depicted on postcards of Hong Kong2.

Water Filtration Principles Discovered After Implementation

At that time, it was widely believed that slow sand filtration was solely a physical filtration process, achieved by screening out the impurities. However, it was not until the late 19th century that studies revealed that water purification was mainly achieved through the activities of the gelatinous layer of living matter gradually deposited on the surface of the filtering medium. Therefore, in general the longer a filter is in use, the more efficient it becomes, provided that the surface layer does not become so dense that it interferes with the flow of water. These findings overturned the traditional practice of frequent cleaning of a filter bed3.

With effective water filtration in place, it was unacceptable for water to become turbid after heavy rainfall. As a solution, the government constructed a slow sand filter bed near the city’s first reservoir, Pok Fu Lam Reservoir. Similar facilities were gradually introduced to other parts of Hong Kong Island. Until 1925, that the Public Works Department first introduced rapid gravity filtration during the Bowen Road Filter Beds Conversion Project. Rapid gravity filtration is a technique that relies on physical screening to eliminate impurities and has the advantage of a rapid filtration speed and a smaller required land footprint. To complement rapid gravity filtration, chemicals such as alum and hydrated lime are added to the raw water prior to helping impurities to precipitate and to regulate the pH value. To facilitate this process, a chemical house is built next to these plants.

Water Filtration Rates Increased After Automated System Introduced

By 1928, there were already eight water treatment facilities in Hong Kong. The recently finished Shek Lei Pui Water Treatment Works was constructed as an additional water treatment facility to complement the Kowloon Group of Reservoirs, alongside the Kowloon Slow Sand Filtration Plant. It is located to the south of the Kowloon Reception Reservoir and backed by the service reservoir. As the area was not considered large enough for a slow sand filter, the Public Works Department decided to use rapid gravity filtration and imported an automatic filter sand backwashing facility from the United Kingdom. There were only two such units operating in London at the time. This method eliminated the need for manual backwashing and the work processing time was ten times faster4. It was the most advanced technology at that time, using hydro turbines rather than coal to power the facility, thereby eliminating the need for manual operations. The performance of the filtration process was found to be satisfactory. Government bacteriologist E.P. MINETT wrote in his operation report that Kowloon raw water was consistently superior to that on Hong Kong Island for unknown reasons. Kowloon filtered water underwent weekly chemical and bacteriological examination before chlorination and the results showed that the quality of filtered water from rapid gravity filters was of exceptionally good quality5.

It is worth mentioning that the construction of the Shek Lei Pui Water Treatment Works was undertaken by Yee Lee & Co., co-founded by NG Wah and TAM Shiu-hong. The latter is well known for risking his life to assist burying the 72 Martyrs at Huanghuagang. Tam became a renowned architect in Hong Kong with many of his projects awarded bonuses for their good management, excellent workmanship and early completion.

There were eleven water treatment works in Hong Kong by 1949. This year, the Eastern Filters was commissioned. It filtered all raw water delivered through the Tai Tam Water Tunnel, replacing the pre-war sand filters at Bowen Road, Albany and Eastern. As a result, the Eastern Filter can filter eleven million gallons of water per day, which is four million gallons more than the combined capacity of the three old sand filters.

Water consumption had increased dramatically after the war and these new treatment facilities were extremely important to Hong Kong. The existing filter beds had become overloaded and filtering bottlenecks occurred when their capacity was exceeded. On many occasions, the city experienced limited hours of water supply due to the inadequacy of the filter beds, despite reservoirs being at capacity and often overflowing at the same time6.

Water Treatment Works as a Water Supply System Hub

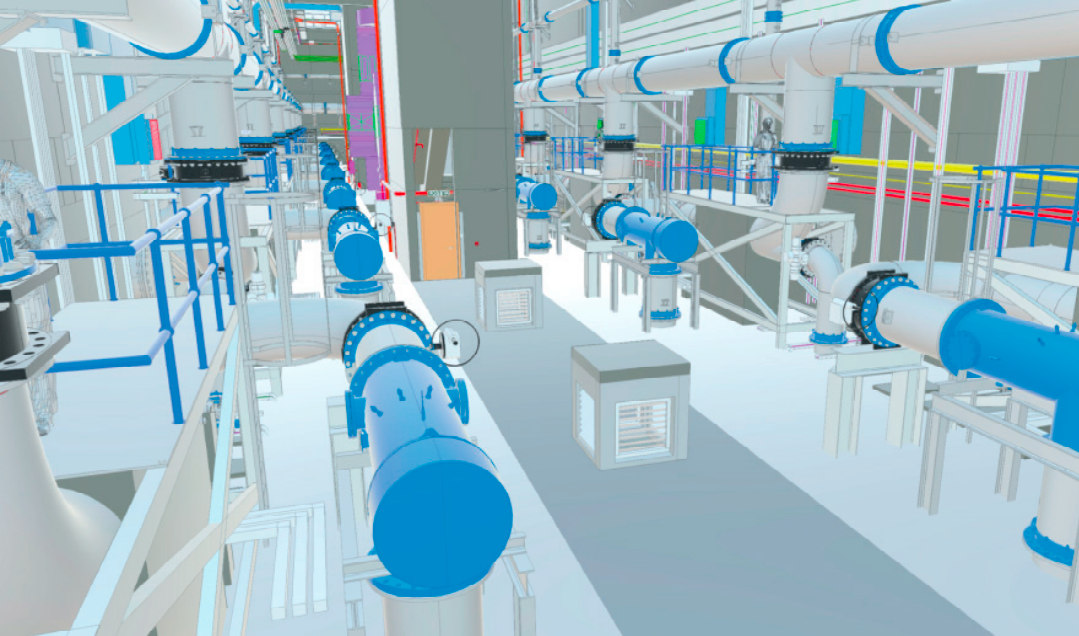

In 1959, the government decided to build the Plover Cove Reservoir to secure a stable water supply for all of Hong Kong. Consequently, the water distribution system is vast and complex. The Sha Tin Water Treatment Works (STWTW) is the hub of the entire water supply system with a central control room to remotely monitor and control the operation of the Plover Cove Reservoir water supply system. At the time, it was the most modern water treatment works in Southeast Asia, occupying 800,000 square feet with the capacity to treat up to 727,000 cubic metres of water per day. Its main facilities encompassed filter beds, pumping stations, chemical houses and administrative offices. Its laboratory was equipped with the most advanced equipment. These facilities established a benchmark for water treatment works in operation at the time.

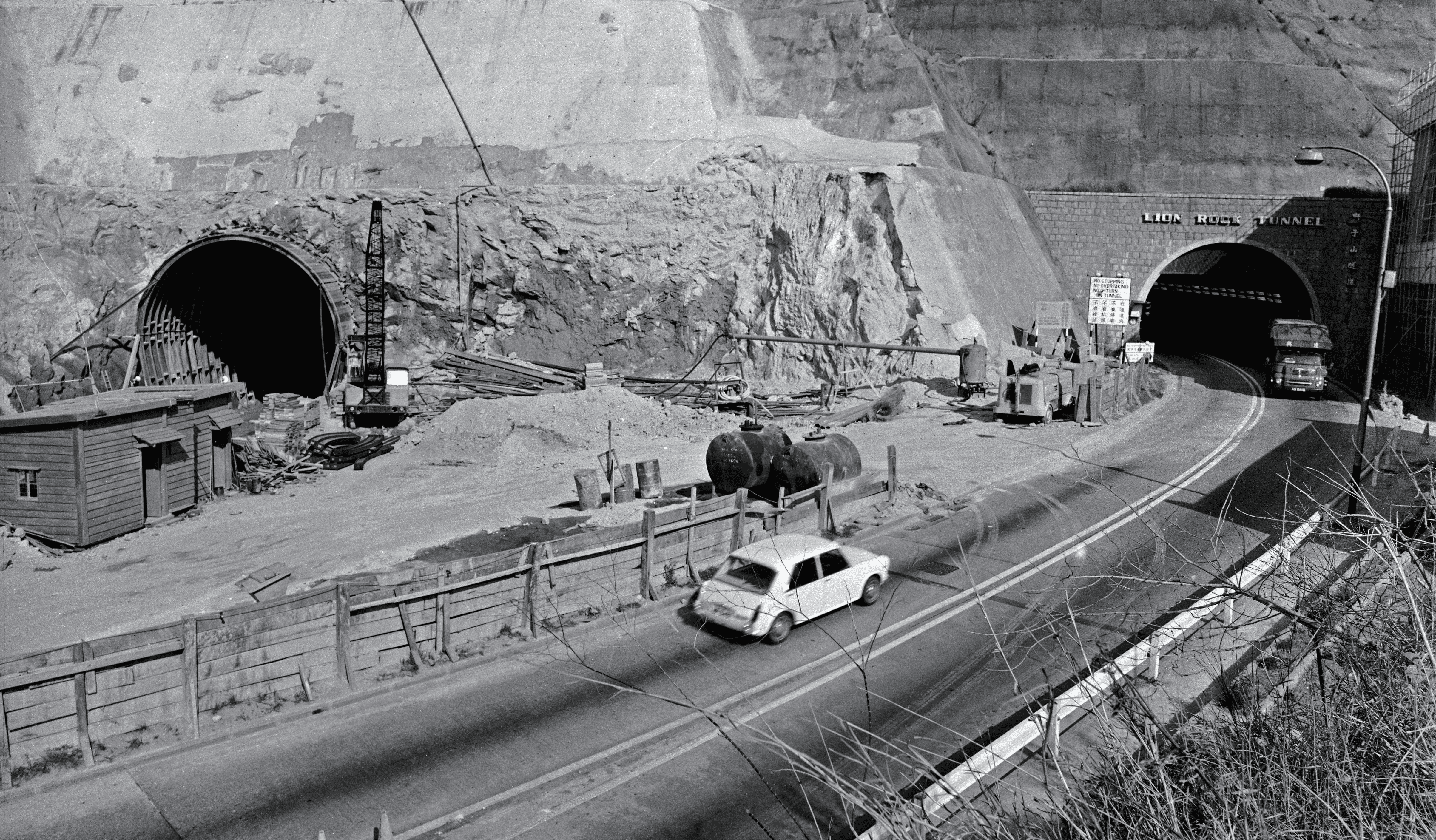

During the constructing of the STWTW, the (vehicular) Lion Rock Tunnel was also included in the same construction works. These seemingly disparate projects are in fact now part of the city’s water supply network. The construction of the Lion Rock Tunnel was initially proposed by the Waterworks Office of the Public Works Department to transfer water from the STWTW to Kowloon. The plan was to cut through the mountain range separating Kowloon from the New Territories. In the early 1960s, when the government was keen to develop Sha Tin into a new town, it also took the opportunity to build a road tunnel alongside the water mains works, making it the first road tunnel in Hong Kong.

New Water Treatment Technologies after 2000

On-site Chlorine Generation

The water treatment works in Hong Kong use an average of six tonnes of chlorine per day. As there are no local suppliers of chlorine gas, it was imported in liquid form from the mainland. The chlorine is liquefied beforehand to make transportation over long distances more convenient.

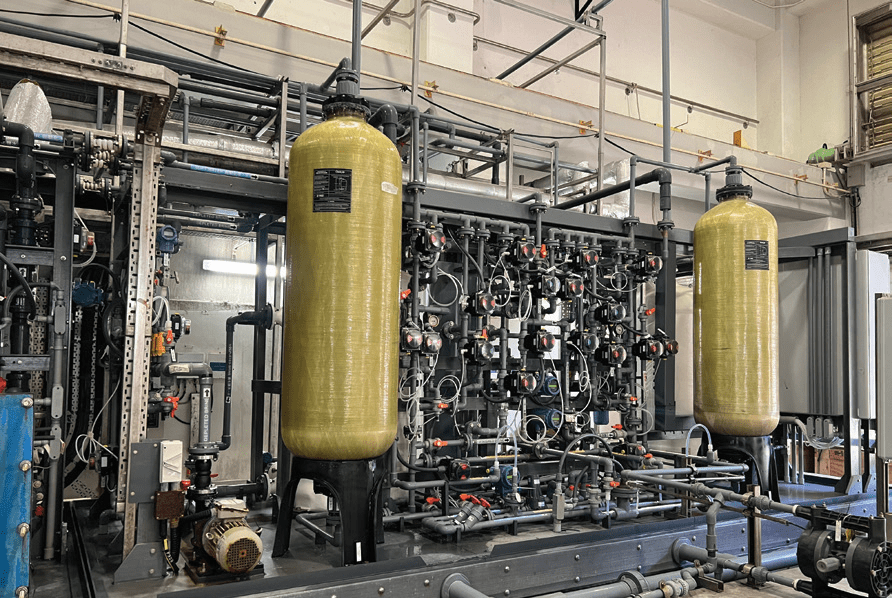

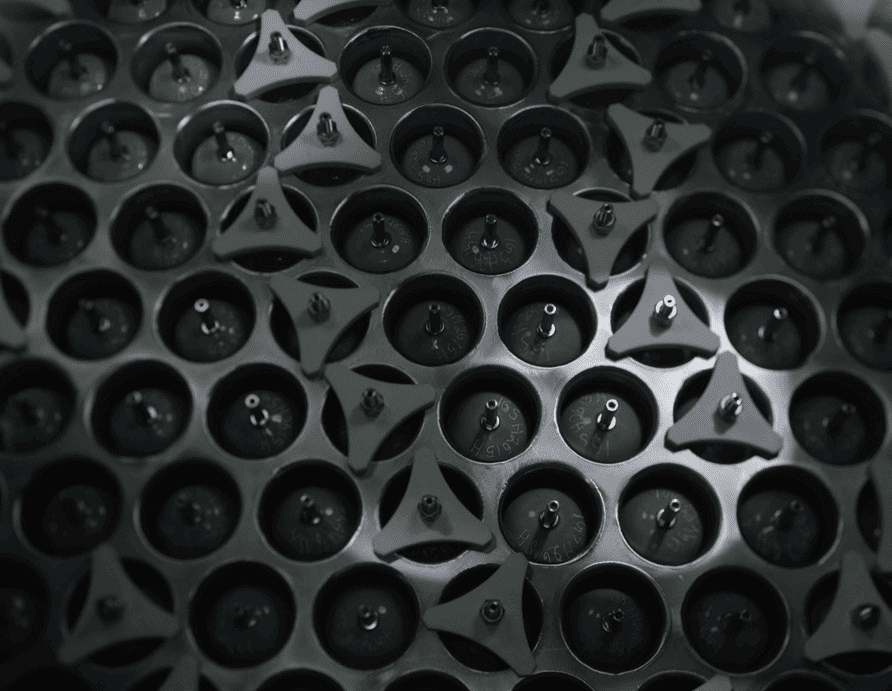

Leveraging technological advances, chlorine generation has become increasingly sophisticated and reliable. As membrane electrolysis technology has improved in performance, the system to generate chlorine is now more efficient and compact in design. Since 2018, the WSD has in phases installed chlorine generation facilities at eleven major water treatment works. Chlorine is produced by electrolysis of brine with the electrodes separated by selective ion membranes. The system can safely and reliably produce chlorine on demand, eliminating the need for storage.

Chlorine generated in this process can also be converted into sodium hypochlorite solution through another simple chemical process. This is transported to other smaller water treatment works to replace liquid chlorine for disinfection. The transportation of sodium hypochlorite solution is safer than moving liquid chlorine.

Ozone Disinfection

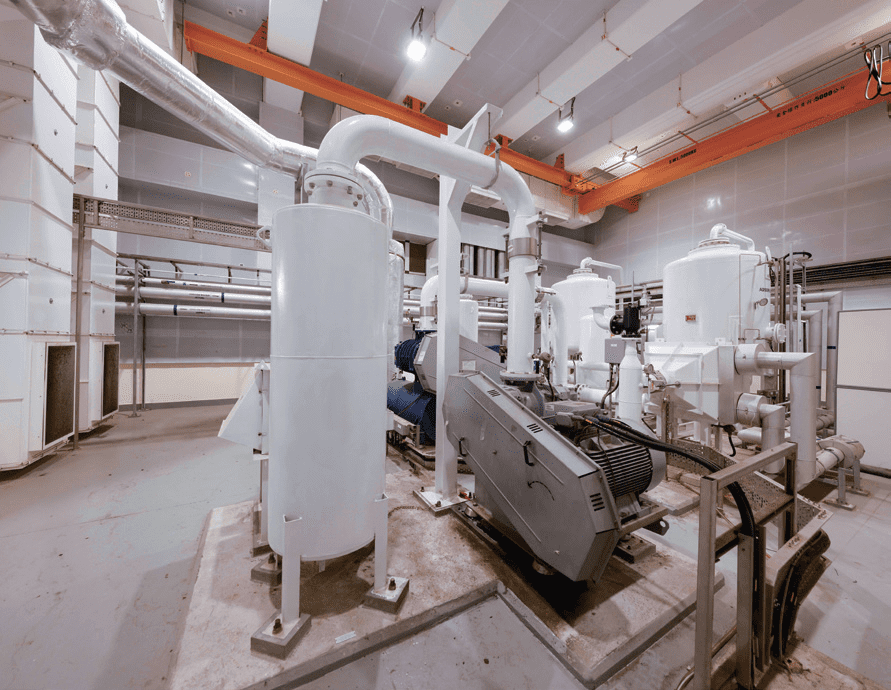

Nowadays, it is preferable to reduce the amount of chemicals used in water treatment. Technological developments have made it possible to replace "pre-chlorination" with ozone. Ozone is a powerful oxidant and disinfectant that inhibits cell reproduction by oxidising bacterial and viral cell bodies, breaking down cell membranes and cell walls, and further destroying deoxyribonucleic acid (DNA) and ribonucleic acid (RNA) in the nucleus of cells. After the oxidation reaction, ozone will be reduced to its oxygen form without producing any odour or residues.

As ozone is liable to decomposition and cannot be stored, it must be manufactured on site and used immediately. In 2000, Ngau Tam Mei Water Treatment Works was the first to introduce ozone disinfection technology into the treatment process, significantly reducing operation costs and the risk of gas leakage associated with chlorine use. This innovation saw the water treatment works receive the prestigious “Superior Achievement Award” from the American Academy of Environmental Engineers in 2001.

The use of ozone to replace "pre-chlorination" has reduced chlorine consumption by approximately 30%. However, ozone is liable to decomposition and cannot be effective in water for a long period of time. So, to prevent bacterial regrowth in the distribution network and maintain disinfection, "post-chlorination" remains in place to ensure that a certain amount of residual chlorine is retained throughout the water distribution system to maintain disinfection effectiveness.

Ultraviolet Light for Water Disinfection

After its commissioning in 2026, the South Works of STWTW will be one of the water treatment works using ultraviolet (UV) light for drinking water disinfection, which is more commonly used in wastewater treatment. In recent years it has also become widely used for treating drinking water. The aim of UV disinfection is to eliminate microorganisms instantly by destroying the structure of their nucleic acids, DNA and RNA, and killing their biological cells or suppressing their active form. Studies and tests find this treatment effective in eliminating pathogenic microorganisms, such as Cryptosporidium and Giardia, as well as other viruses.

Biosensing Alert System with Dual Protection

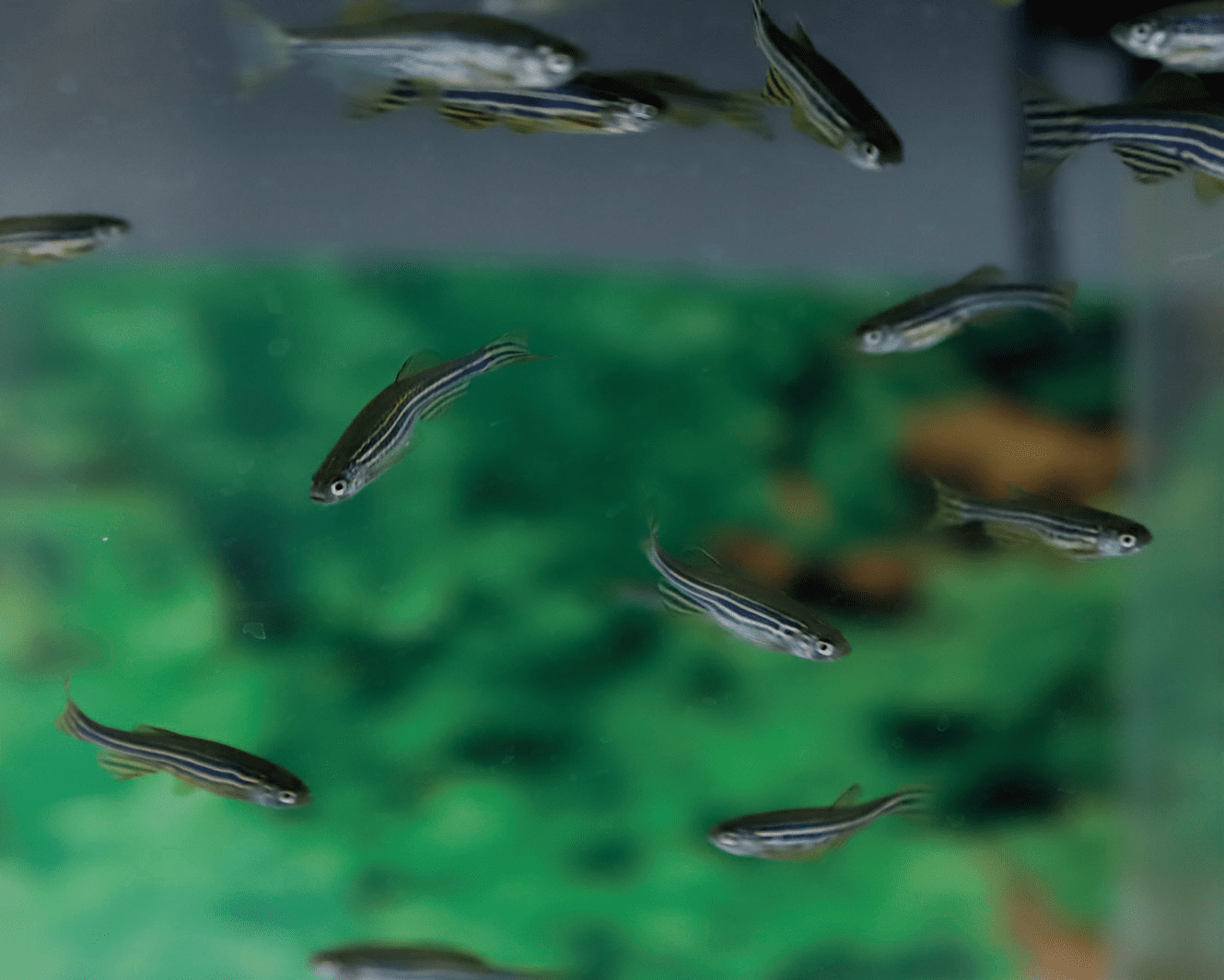

Although advanced analytical instruments are capable of detecting chemical contaminants in water at microgram or even nanogram levels, the results of trace analysis generally require a longer time to be delivered. The WSD has developed and introduced a "Biosensing Alert System" featuring dual protection and validation capabilities to enhance water quality monitoring. Biosensing refers to organisms responding to changes in their surroundings. Therefore, tracking the specific reactions of individual organisms can be used for proactive monitoring. At present, the WSD has chosen zebrafish and vibrio fischeri as its water quality monitoring collaborators. Zebrafish can monitor the water quality round the clock, and vibrio fischeri can rapidly test the toxicity of water. When used together, frontline staff can identify and resolve water quality issues within an hour.

Zebrafish

Zebrafish are genetically similar to humans by up to 70%. They are exceptionally sensitive to contaminants in water and are highly responsive, providing fast and accurate warning of water safety issues. During their “service”, zebrafish are placed in a specially designed fish-tank. Raw water is continuously fed into the tank and a high-speed video camera is used to record and analyse the movement of the zebrafish 24 hours a day. If they show any abnormalities such as hypoactivity, suffocation or irritation, the system will alert the staff on duty. Water samples will be taken automatically for testing.

The zebrafish water quality monitoring system is the result of in-house research and development by the officers in the Water Science Division. The system integrates biological, computer, telecommunication and automation technologies. The video tracking of zebrafish is particularly challenging. Even simple things like lighting and the frequency of light-tube flickering, which are imperceptible to the naked eye, can be detected by a high-speed camera. Other hardware considerations, such as the thickness of the fish tank, material colour, water-flow control, and even air bubbles and reflections in the water can affect the clarity and accuracy of the recording tracking. After more than two years of experiment and refinement, the design of the fish-tank has already evolved to the eighth generation by the time the Biosensing Alert System was put into service.

The system won a Silver Award in the Civil Service Outstanding Service Award Scheme's Team Collaboration Award (Internal Service) and a Bronze Award in the Service Enhancement Award (Large Department Category) in 2013. It not only facilitates close monitoring of water quality, but also reduces the number of laboratory tests, resulting in a significant reduction in chemical and energy consumption. It is both cost-effective and in line with green science and environmental principles.

Vibrio fischeri

Vibrio fischeri, commonly known as "light-emitting bacteria", emits blue-green light under normal water conditions. While, on the contrary, it may be less luminous or even non-luminous, researchers have used this property to develop a rapid detection system based on bioluminescence technology. When water samples contain harmful substances that inhibit vibrio fischeri from emitting light, the rapid toxicity testing system based on the bioluminescent technology is capable of screening over 1,000 harmful substances in water, such as formaldehyde and cyanide, in an hour. The test has the advantages of a short result time, low cost, high accuracy and sensitivity, and it has been approved by the United States Environmental Protection Agency and has been adopted by the Olympic Games, Asian Games and the United States Department of Defense to ensure water safety.

- O. Chadwick (1882). Mr. Chadwick’s reports on the sanitary condition of Hong Kong; with appendices and plans. London: Printed by George E.B. Eyre and William Spottiswoode, for Her Majesty’s Stationery Office. 37. https://wellcomecollection.org/works/mpnmmdbz

- Shepherd, Bruce (1982). The Hong Kong Guide 1893. Hong Kong: Oxford University Press. 94.

- Francis A. Cooper (1896). Report on the Water Supply of the City of Victoria and Hill District Hong Kong, Public Works. Sessional Papers for the Year 1896. 14. https://digitalrepository.lib.hku.hk/catalog/dr274p440#?c=&m=&s=&cv=&xywh=-231%2C676%2C2359%2C1173

- Tam, Shiu Hong. (1954). Memories of 50 Years of Building Works in Hong Kong. Year Book of Hong Kong Construction Association. Hong Kong: Hong Kong Construction Association. 50.Retrieved from https://sites.google.com/yahoo.com.hk/tamfamily/tam-shiu-hong-tbcahk-%E8%AD%9A%E8%82%87%E5%BA%B7%E8%88%87%E9%A6%99%E6%B8%AF%E5%BB%BA%E9%80%A0%E5%95%86%E6%9C%83/memoir-of-50-years-of-construction-history-in-hk?authuser=0

- E.P.Minett. (1930). A review of the Water Supplies of Hong Kong. Transactions of The Royal Society of Tropical Medicine and Hygiene. 3-4.

- Six points to be explained: Water ban remains unresolved as filtering capacity cannot cope with full-day water supply. (23 June 1950). Wah Kiu Yat Po. 5. Retrieved from https://mmis.hkpl.gov.hk/coverpage/-/coverpage/view?_coverpage_WAR_mmisportalportlet_actual_q=%28%20%28%20%2Bdc.identifier.bibno%3A%28NPWK19500623%29%20%29%29&_coverpage_WAR_mmisportalportlet_sort_field=score&p_r_p_-1078056564_c=QF757YsWv58JCjtBMMIqoivUNh%2BPDT4X&_coverpage_WAR_mmisportalportlet_o=0&_coverpage_WAR_mmisportalportlet_sort_order=desc