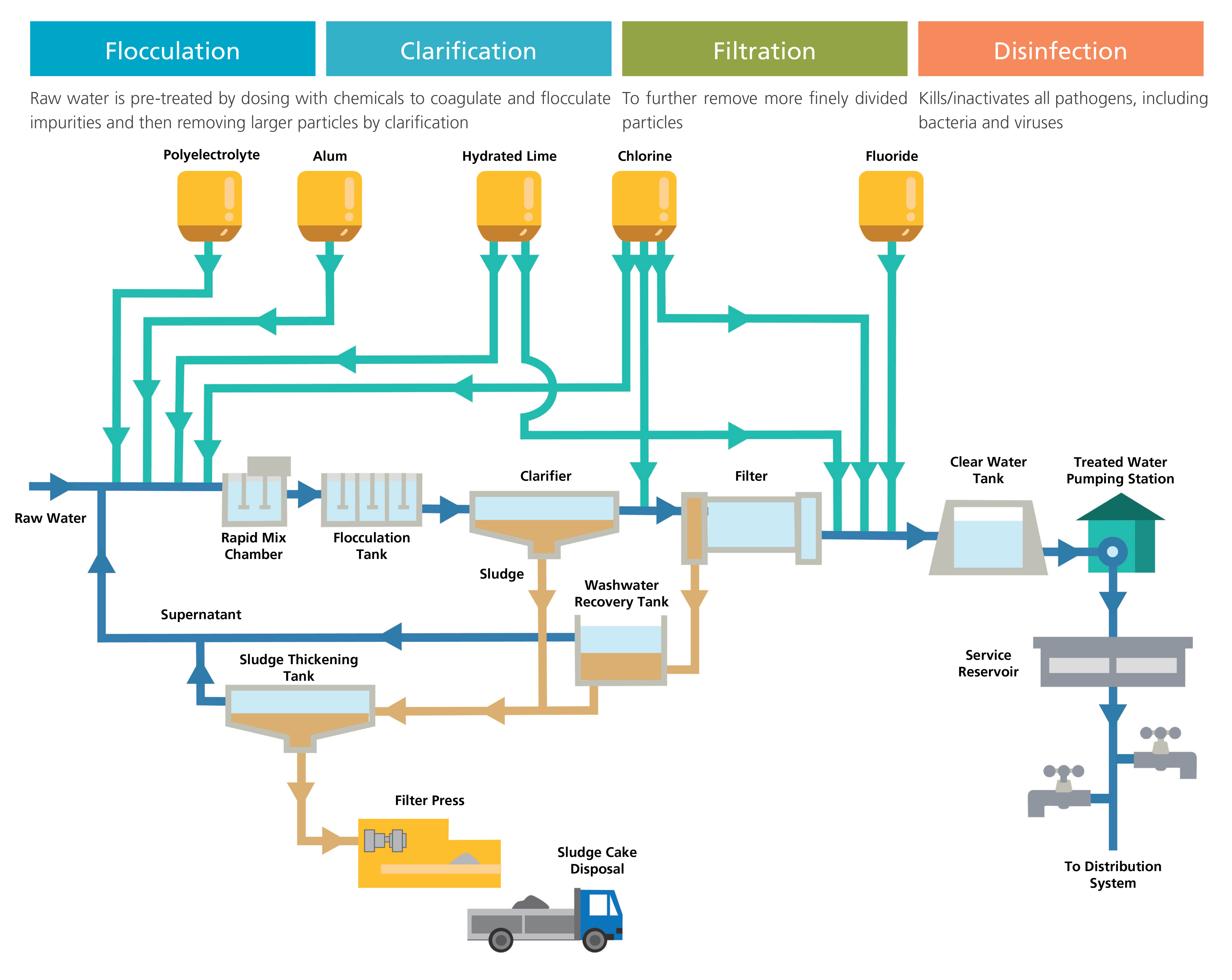

A series of purification processes - generally referred to as water filtration - makes raw water safe for drinking and consumption. Water filtration entails processes for removing or reducing suspended particles, metals, organic matter and microorganisms that are naturally present in the water, and of other unhealthy chemical contaminants.

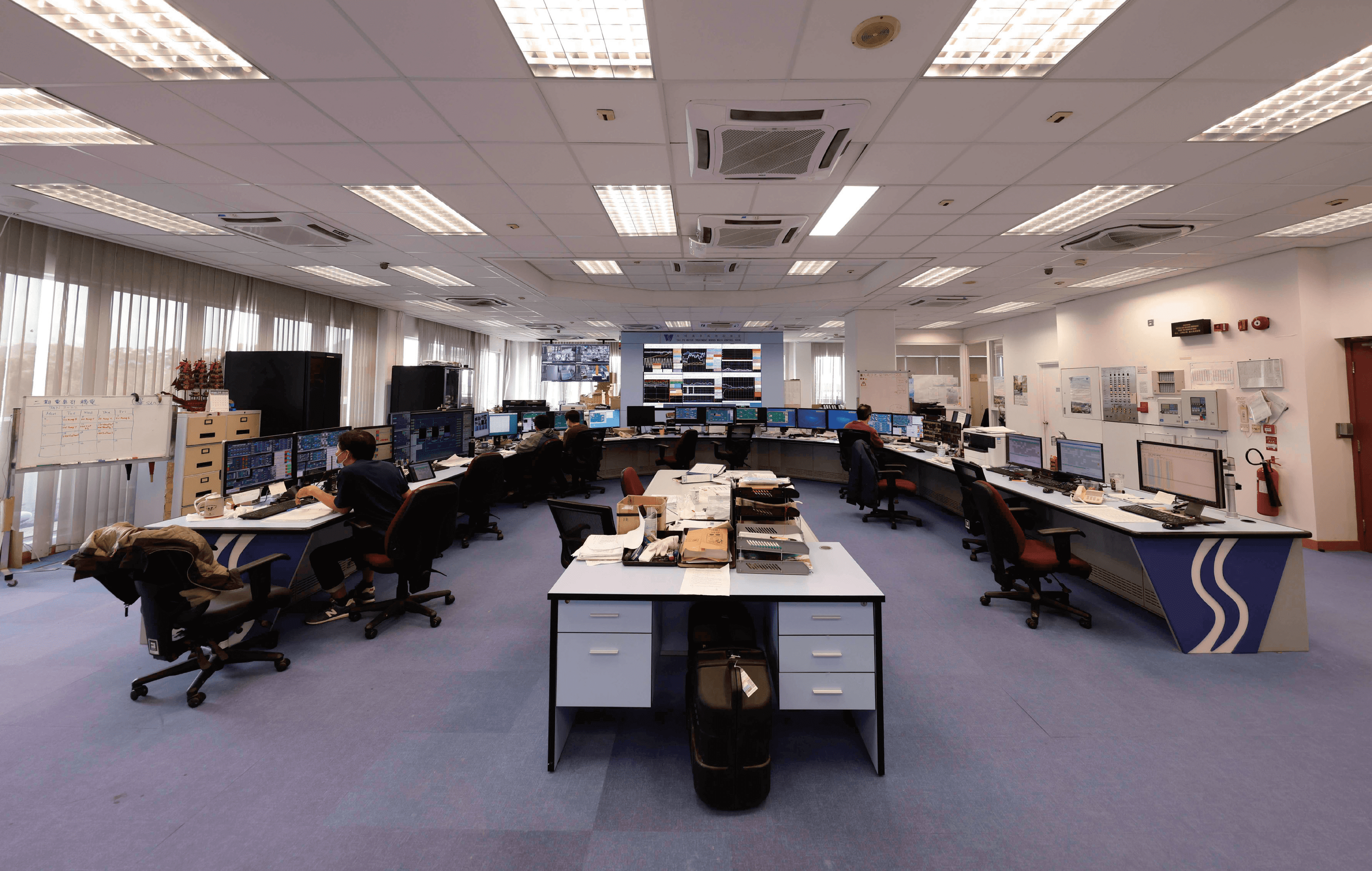

Currently, there are 20 water treatment works in Hong Kong operated by the WSD and separated into the following four regions: Hong Kong Island and Outlying Islands, Kowloon, New Territories West and New Territories East. Using the city’s raw water sources and reservoir systems, 4.7 million cubic metres (mcm) of raw water can be treated daily to meet the demands of the public. The water treatment works have been built at different times, with improvements and upgrades according to the city’s water quality needs and the best technology available at the time. The water treatment process principally comprises the following four stages: flocculation, clarification, filtration and disinfection. This purification process removes impurities, ranging in size from large to small, in the raw water, and the dosing of chemicals, as appropriate. The water treatment works also has the important role of water quality monitoring and control. To meet the Hong Kong Drinking Water Standards, the monitoring of the quality of incoming raw water, the water quality and performance at each stage of the treatment process ensures that the treatment process is performing optimally (see the article "Hong Kong’s Drinking Water Standards" in Chapter 5).

The diagram below shows a typical water treatment process that ensures treated water is clear, clean and free from pathogens to a standard safe for direct consumption.

The Four Stages of Water Treatment

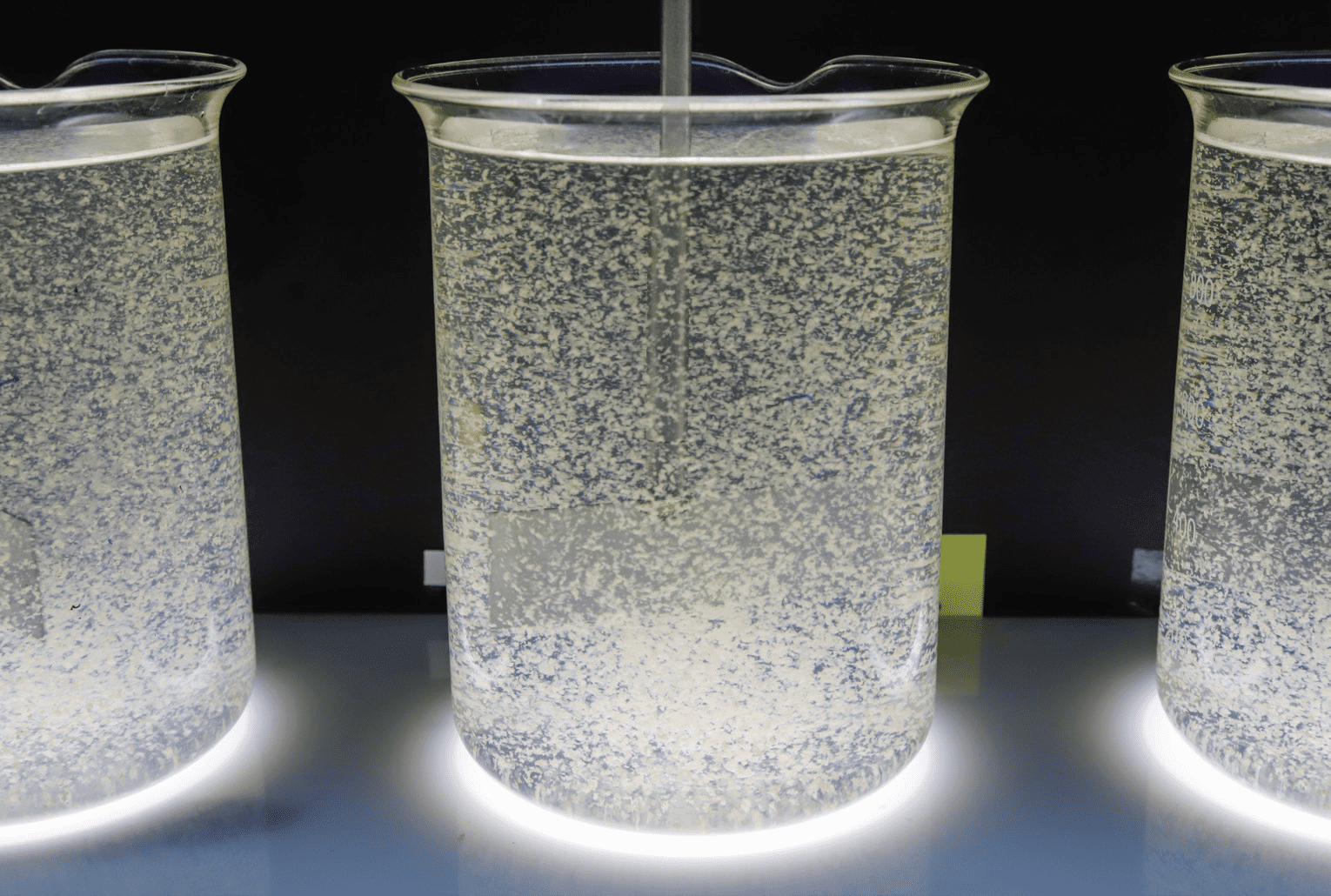

The traditional method of water purification relied on gravity to draw down suspended solids - those with a higher density than water - to the bottom of a pond from which they could be removed. To speed up this sedimentation process, raw water is pre-treated with chemicals such as alum. This helps the fine suspended impurities to coagulate and flocculate into larger and denser particles through a process known as flocculation. Hydrated lime is also added to regulate the pH level of the raw water within the range of 6.4 and 7.2 to achieve the desired flocculation result.

Clarification refers to the process of raw water being mixed with a coagulant and the suspended particles in the water coagulate into large floc particles which are then removed. Currently, four technologies are used in Hong Kong’s typical water treatment works: solid contact clarification, high rate clarification, multi-deck sedimentation and dissolved air flotation.

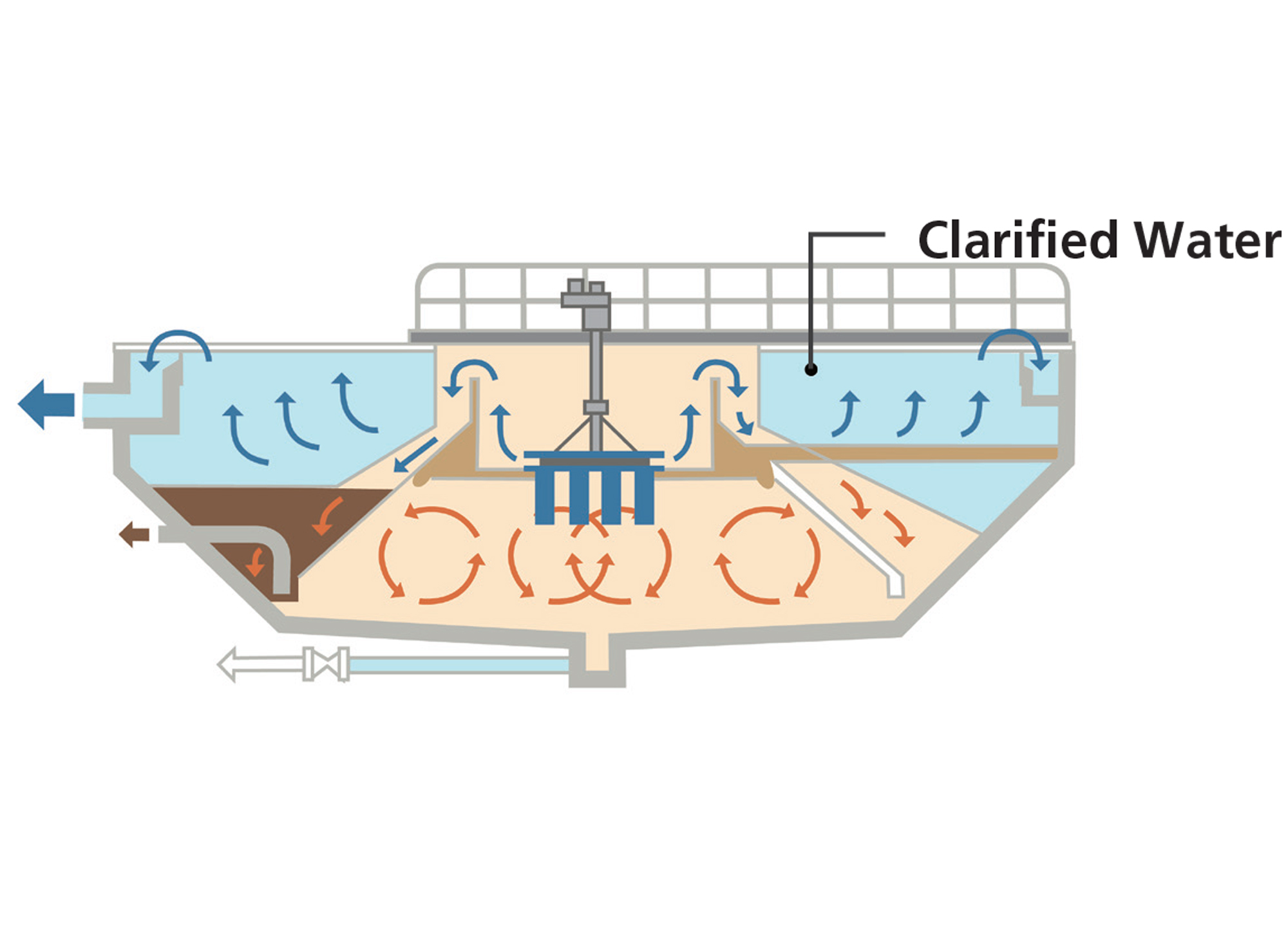

Solid contact clarification is an older design consisting of mixing impurities together to form a stable and evenly distributed layer of suspended sludge blanket. As the flocculated raw water flows from the bottom to the top of the clarifier, the impurities coalesce with the suspended sludge blanket and the clarified water is collected on the top of the clarifier. A key feature of the Sha Tin Water Treatment Works is that these clarifiers are usually circular reinforced concrete tanks due to the need for a strong actuator to drive the flocculation cycle.

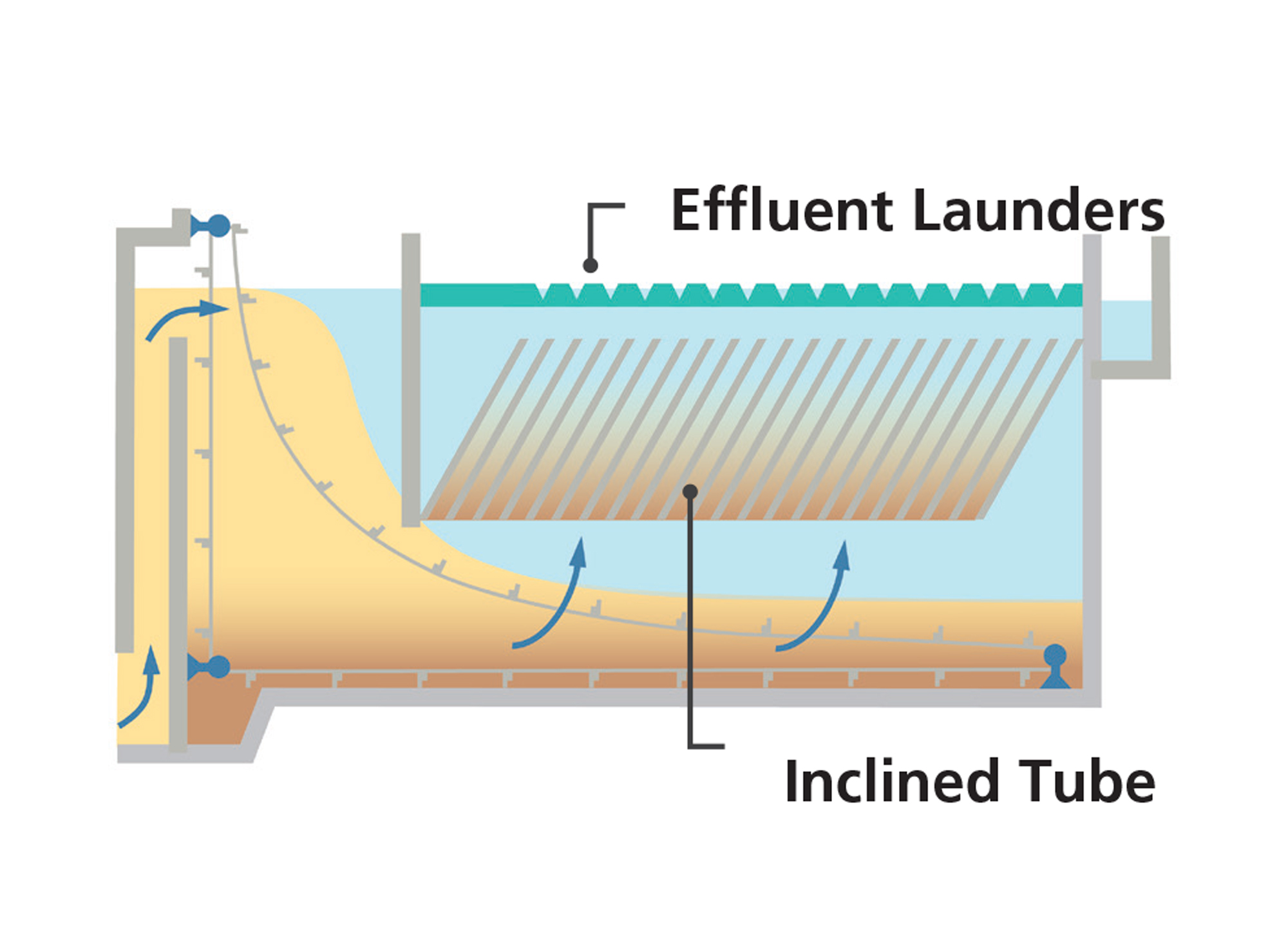

The lamella clarifiers are installed with a row of inclined tubes. As the flocculated raw water flows upwards through the inclined tubes from the bottom of the tank, the impurities in the water settle on the bottom surface of the inclined tube. Once the impurities have reached a certain weight, they will sink to the bottom of the tank by gravity. The clarified water then rises to the effluent launders.

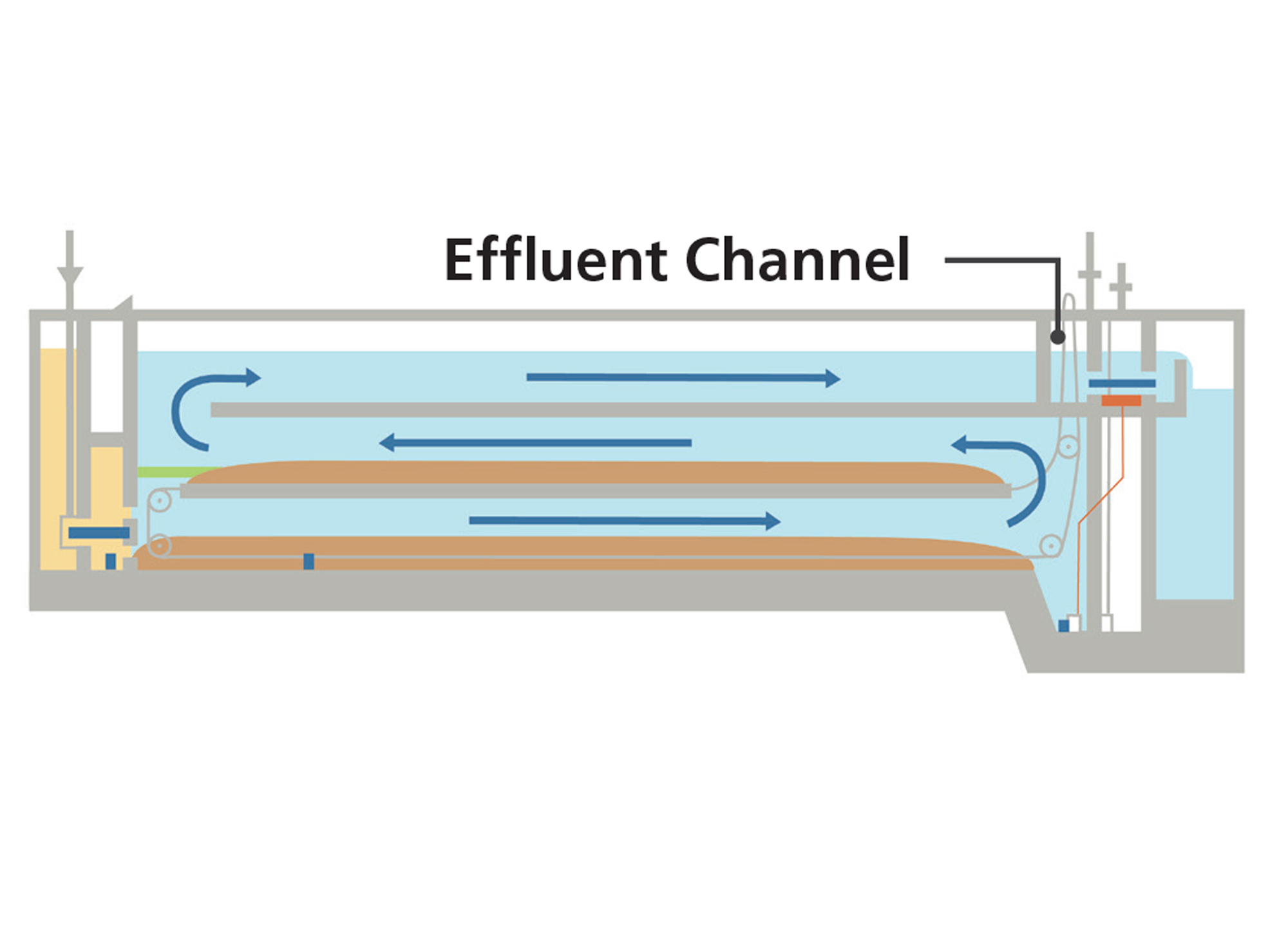

The clarifier is constructed as a three-tray tank to conserve space and facilitate the sedimentation of flocs. The bottom and middle decks are each equipped with a scraper. Following flocculation, the water flows from the bottom to the top deck, with the larger flocs first settling in the bottom deck, followed by the second deck where the lighter particles settle, and so on. The raw water, after flocculation, settles three times before it flows through the top deck to the filter beds.

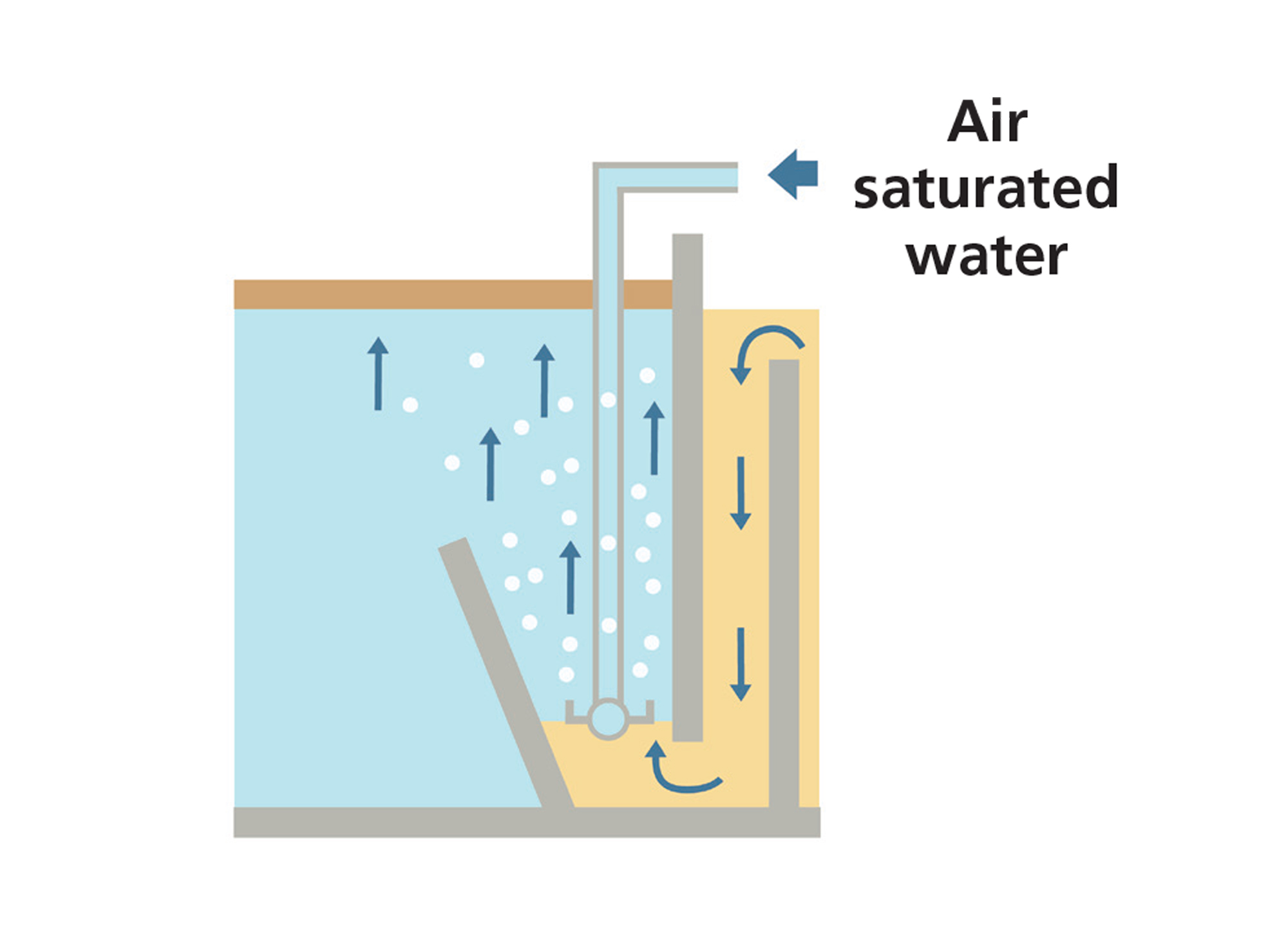

Dissolved air flotation is a rather new treatment technology for water clarification. In comparison with the conventional method of sedimentation for clarification, this new process brings suspended material to the surface quicker. It involves saturating the water with compressed air to generate numerous fine air bubbles that attach to the suspended material and lift it to the surface, forming a ‘sludge blanket.’ A movable scraper in the clarifier removes the ‘sludge blanket’ and the clarified water is transported to other water filtration facilities through pipes near the bottom of the tank. Dissolved air flotation is a faster method of purification than traditional clarification techniques and reduces the amount of chemicals used.

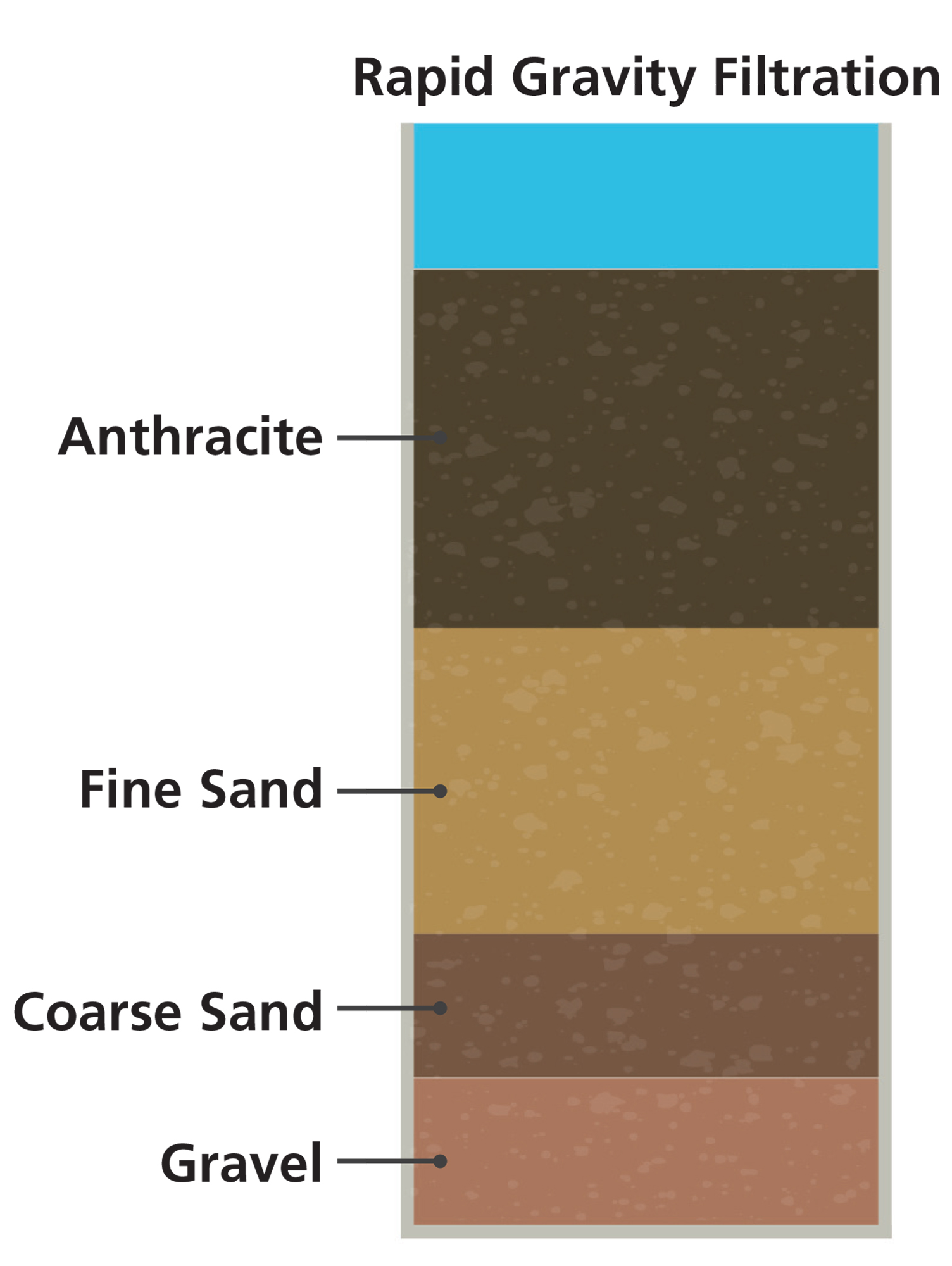

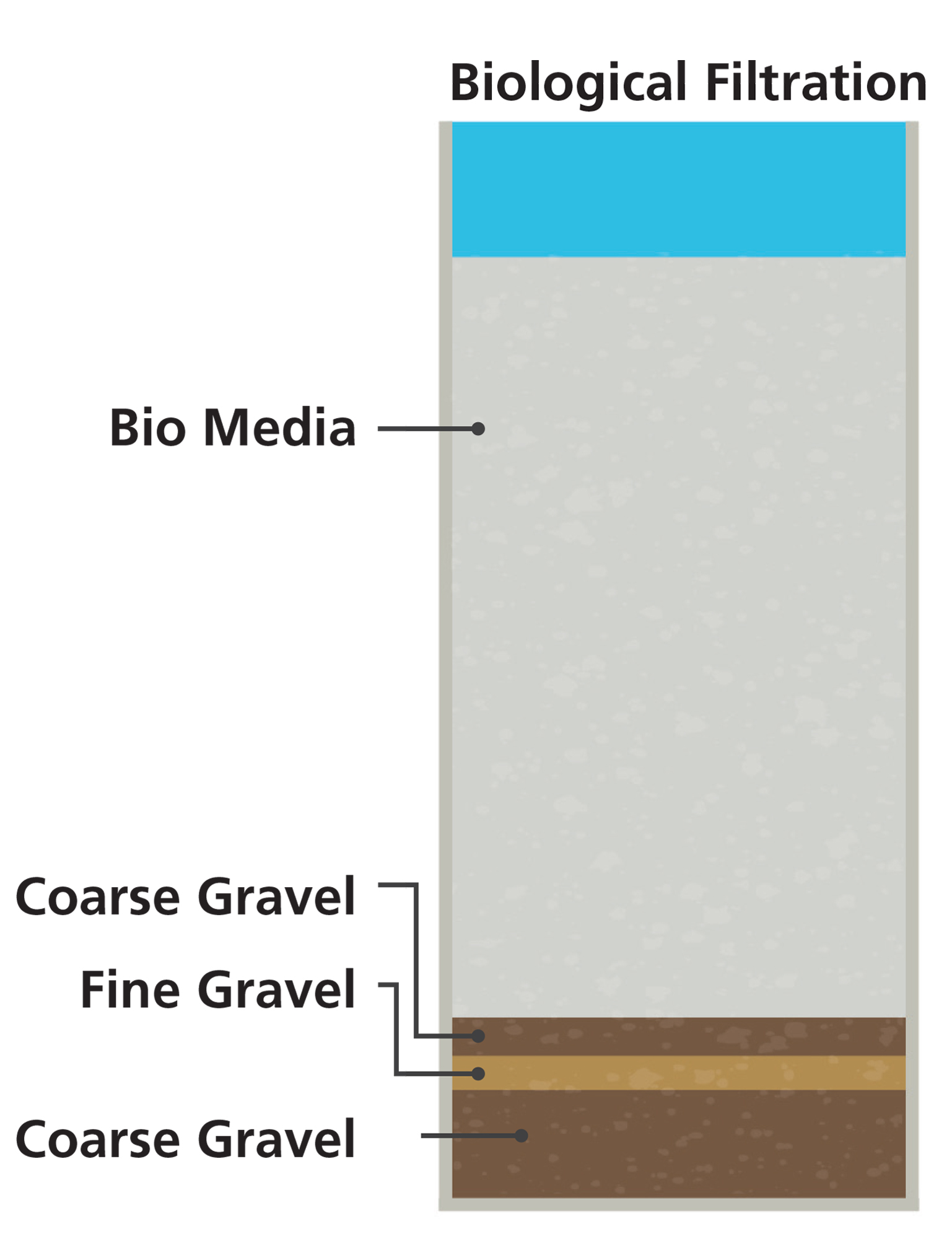

After removing larger particles, water is further filtered to remove impurities through interception. Traditionally this is done by gravity, using a variety of filter media to capture the suspended particles in the raw water, while allowing water molecules to pass through. Two types of gravity filtration are currently used in Hong Kong - the main difference is the type of filtration media used, as explained below.

After the filtration of clarified water, any remaining bacteria and viruses are deprived of the protection of suspended particles, thus creating the conditions for subsequent disinfection. Chlorination is generally used as the most traditional and effective method of disinfection.

In Hong Kong, chlorine is usually applied in two stages of the water treatment process: "pre-chlorination" and "post-chlorination". "Pre-chlorination" refers to the addition of chlorine to raw water or clarified water to oxidise and remove impurities in raw water and suppress the growth of algae. “Post-chlorination" is the addition of chlorine to disinfect filtered water and ensure that the treated water is free of pathogens from the time it leaves the treatment works until it is used.

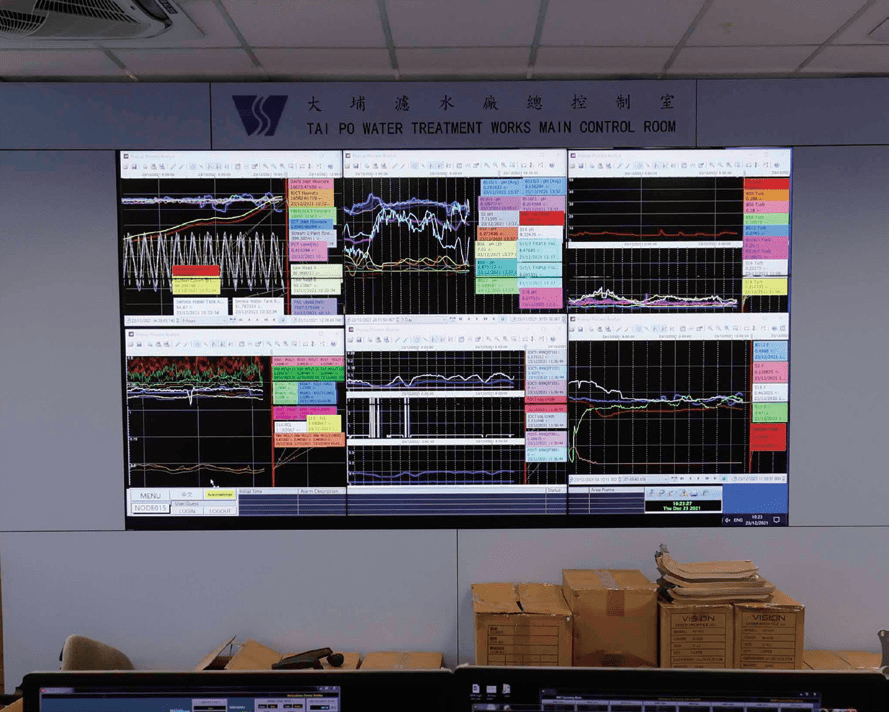

Water Quality Monitoring

Water samples are taken from raw water, flocculated water, clarified water, filtered water and treated water, and are monitored simultaneously and analysed following each step and throughout the water treatment process.

Water quality control at Hong Kong’s water treatment works has implemented a three-tier water quality monitoring system. The first tier is the "Online Water Quality Monitoring System'', which uses various monitoring sensors to monitor different parameters round-the-clock such as pH, turbidity, residual chlorine and fluoride levels in the water automatically and continuously. The second tier is the "On-site Primary Control Test", where grabbed water samples are taken for operational water quality monitoring. This assists in adjusting the required chemical dosage and compares the accuracy against the first tier of online monitoring. The "Comprehensive Water Quality Monitoring" is the third tier, acquiring water samples regularly from every treatment stage and sent to the laboratory for comprehensive physical, chemical, bacteriological, biological, and radiological testing by laboratory staff to ensure compliance with water quality requirements.