The commissioning of a facility is only the start of its public service. Daily maintenance is always required to ensure a facility’s condition and performance is kept at an optimum level. The routine maintenance of the city’s waterworks facilities can be broadly divided into two major categories: mechanical and electrical engineering, and civil engineering. The former involves three main disciplines - mechanical, electrical, and instrumentation. The WSD has maintenance workshops that ensure its facilities - whether over 100 years old or newly completed - are continually and sustainably maintained. To support its work, an apprenticeship scheme from basic to specialised levels for staff has also been established.

Mechanical and Electrical Facilities Maintenance

Although there are no specific heavy industries in Hong Kong, the water supply system serving Hong Kong requires large machinery, and electrical and instrumentation systems, to function. This infrastructure must be capable of transporting raw water from outside the region to reservoirs, then transferring to water treatment works, and finally delivering to households in the city’s different districts. This must all be done while overcoming the geographical challenges posed by hilly terrain and the requirement of operating round the clock throughout the year. For many years, the WSD has nurtured a team of maintenance and repair experts to tackle many technical issues of different complexity, the far-ranging issues they deal with include: pumps that must supply over 320,000 cubic metres (m³) of water each day to households; metering devices able to monitor the water consumed by each household; and, the constant testing of water pipes to ensure water safety. Their stories often reflect those of Hong Kong industry.

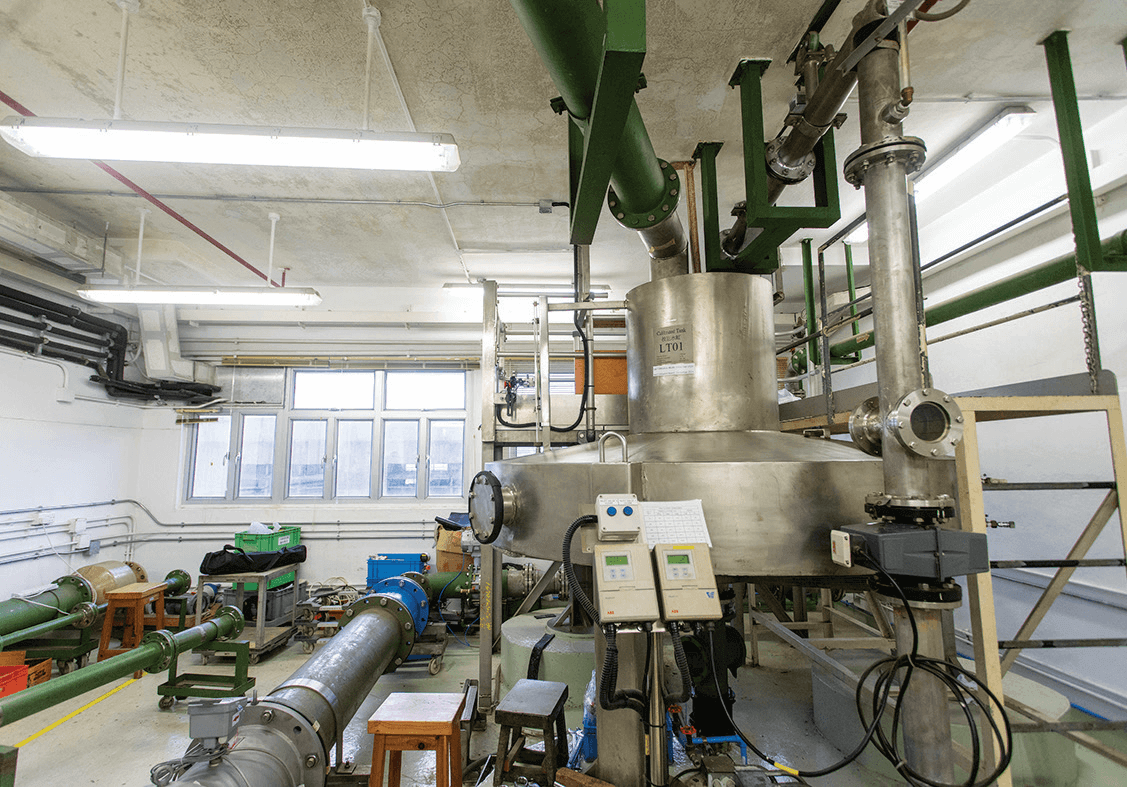

The WSD Lung Cheung Road Mechanical and Electrical Workshop (M&E Workshop), located on the Beacon Hill hillside, is the works depot for all the WSD's mechanical and electrical workshop equipment. It provides professional services for the repair and testing of pumps, motors, water meters and various measuring and remote control equipment. After its completion in 1990, the WSD’s different workshops, including the mechanical workshop, the electrical workshop and the instrument workshop, were consolidated into one maintenance facility. Chief Electrical and Mechanical Engineer Ir LAU Chin-hung, who has been working with the WSD for nearly 30 years and is now responsible for overseeing all mechanical and electrical repairs and maintenance, says that there are 20 water treatment works and about 200 pumping stations in Hong Kong, which require a wide range of equipment and instrumentation. Some of the equipment is large and requires corresponding space and tools for maintenance. This workshop centralises the process and its maintenance equipment is shared amongst staff for more cost-effective management.

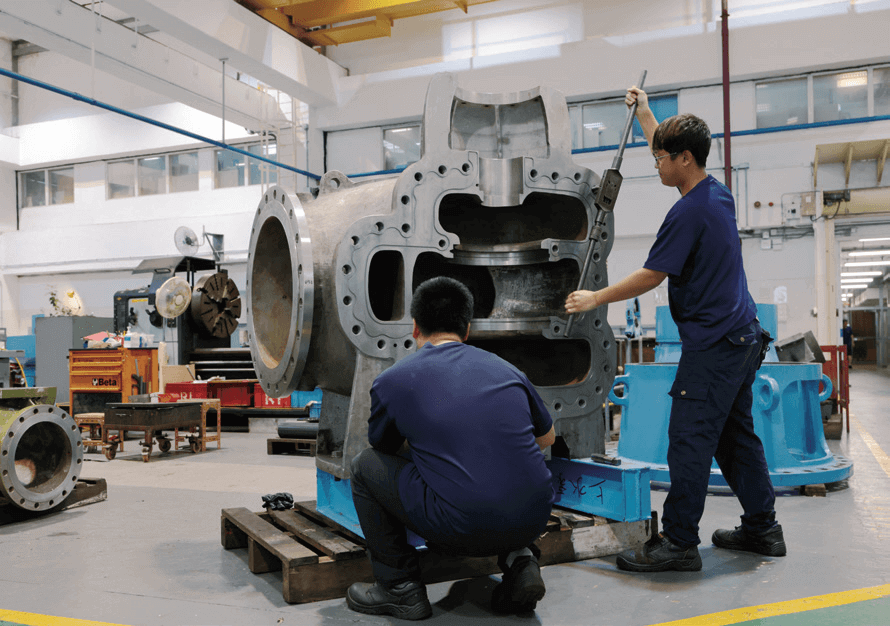

Ir LAU described pumping stations and water pipes as being like the heart and blood vessels of the water supply system. Any issues with the facilities will affect the water supply. Regular inspections and maintenance are necessary to prevent problems before they arise. For instance, a water pump’s motor is sent to the workshop for major maintenance every five to ten years and those for pumping seawater are more susceptible to corrosion and wear out quicker. There are two teams of maintenance staff attached to the workshop, one in the field and another in the workshop. One team attends to outside facilities for daily inspection and maintenance, while the other carries out the overhaul and repair of waterworks equipment in the fully-equipped workshop. According to Ir LAU, the WSD formulates a maintenance schedule based on past years of experience and arranges equipment to be periodically sent back to the workshop for repair and replacement. These measures help maintain facilities at an optimum level.

Maintenance by Categories

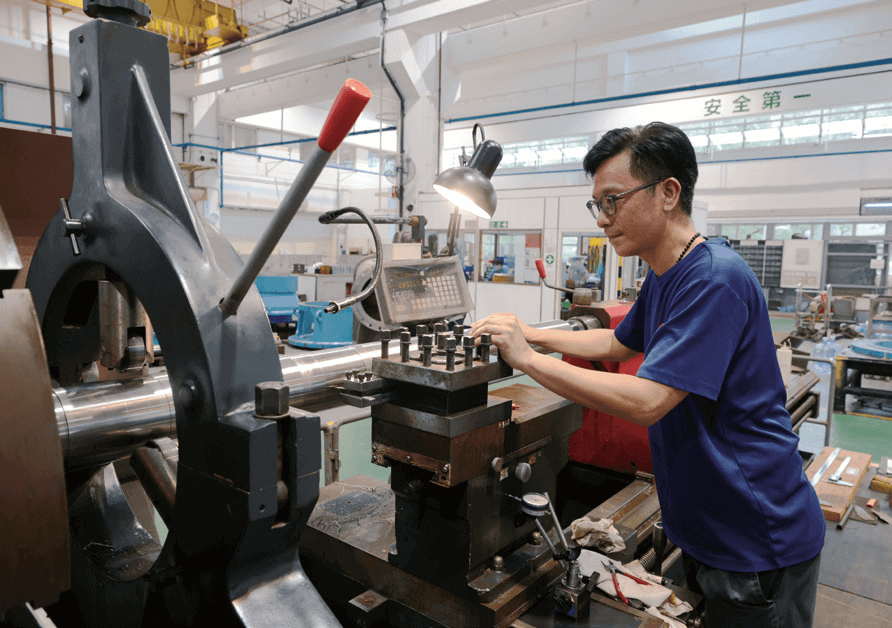

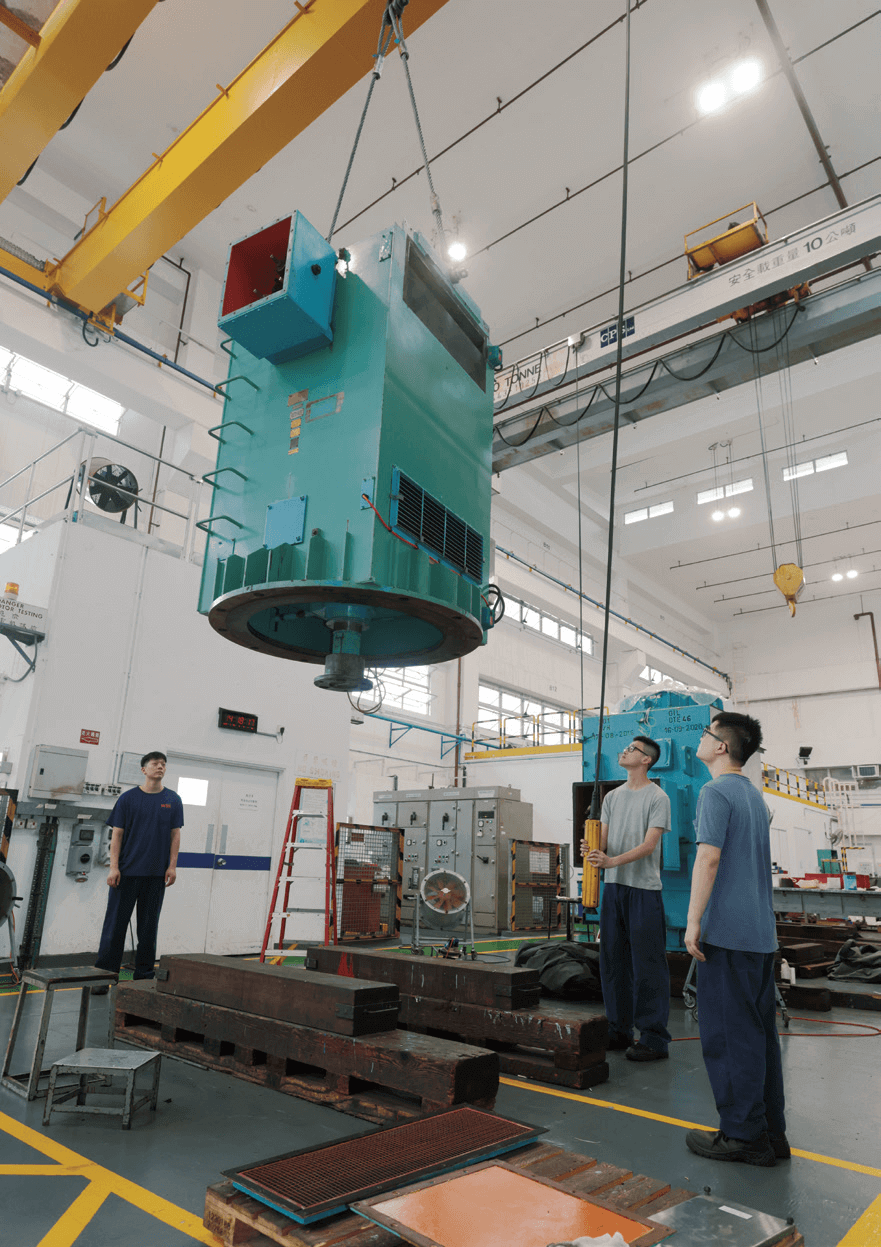

The M&E workshop at Lung Cheung Road comprises Mechanical and Electrical workshops in Block A; a Material Testing Laboratory in Block B; and, a six-storey office building in Block C. The workshop is divided into three main technical areas of expertise: mechanical, electrical, and instrumentation. The mechanical workshop, for example, is equipped with five main workshop areas of expertise, commonly known as "Che, Luo, Pao, Mo, Chuen"1. It also houses a variety of auxiliary equipment, including hydraulic jacks, cranes weighing up to 20 tonnes, electric conveyors and lifting platforms.

The workshop has around 700 staff who have mostly completed the WSD’s apprentice training scheme. Also, the WSD openly recruits people with relevant experience who work in the workshop’s sections based on their expertise or interests. The workshop’s work covers mechanical facilities, and components such as pumps, valves, and gears, while the electrical equipment maintained covers devices, such as high voltage switchboards, low voltage switchboards, and motors. The maintenance of instrumentation equipment encompasses electronic devices, electrical meters and remote monitoring systems, etc.

Introducing New Technologies in a New Era

Ir LAU points out that mechanical and electrical maintenance is a traditional craft skill, which requires knowledge of facility design and principles, as well as maintenance guidelines. He says, “Practices passed-down over the years are crucial for maintenance. Also, we have recently developed remote control devices to collect real-time performance data on our facilities. The maintenance staff can simultaneously monitor the performance of M&E systems in multiple locations from the control room. This enables more effective and accurate problem identification, resulting in timely response and maintenance.”

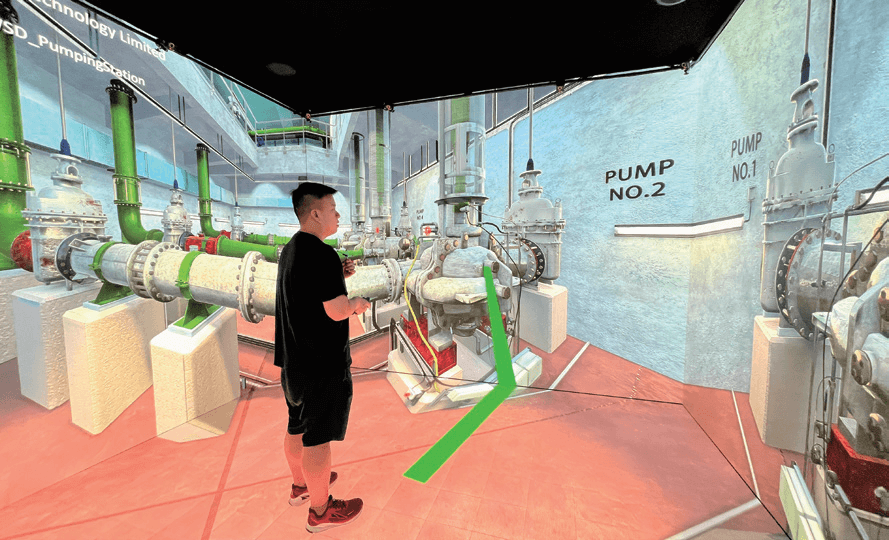

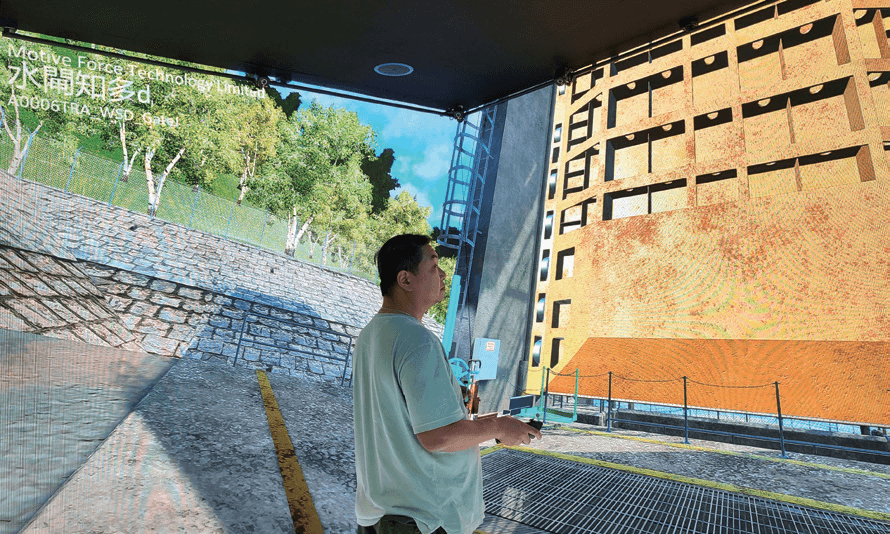

Due to Hong Kong’s ageing population, there has been a shortage of new, younger entrants willing to join the apprentice training scheme to replenish the retired staff in WSD. To alleviate succession gaps in the maintenance of waterworks facilities, the WSD has recently produced additional training materials, particularly for facilities for which staff may only have a rare chance to experience their maintenance. These materials are based on the experience and knowledge of senior maintenance staff and are presented in a virtual reality format. This allows a range of staff to understand the key aspects of maintenance work, as if they were on site. Ir LAU explains: “The largest water pump in Hong Kong is located at the Muk Wu Raw Water Pumping Station in the Frontier Closed Area. It is usually maintained once every few years, and the local private sector has no maintenance experience on a similar scale. As a result, only a few experienced maintenance staff have been able to participate in its maintenance. The development of virtual reality material will enable more staff to gain knowledge in its maintenance.” It is hoped that learning material will be more widely used in the department. Although hands-on experience is necessary for the transfer of actual maintenance skills, virtual reality does a better job than solely relying on photographs, as was done in the past.

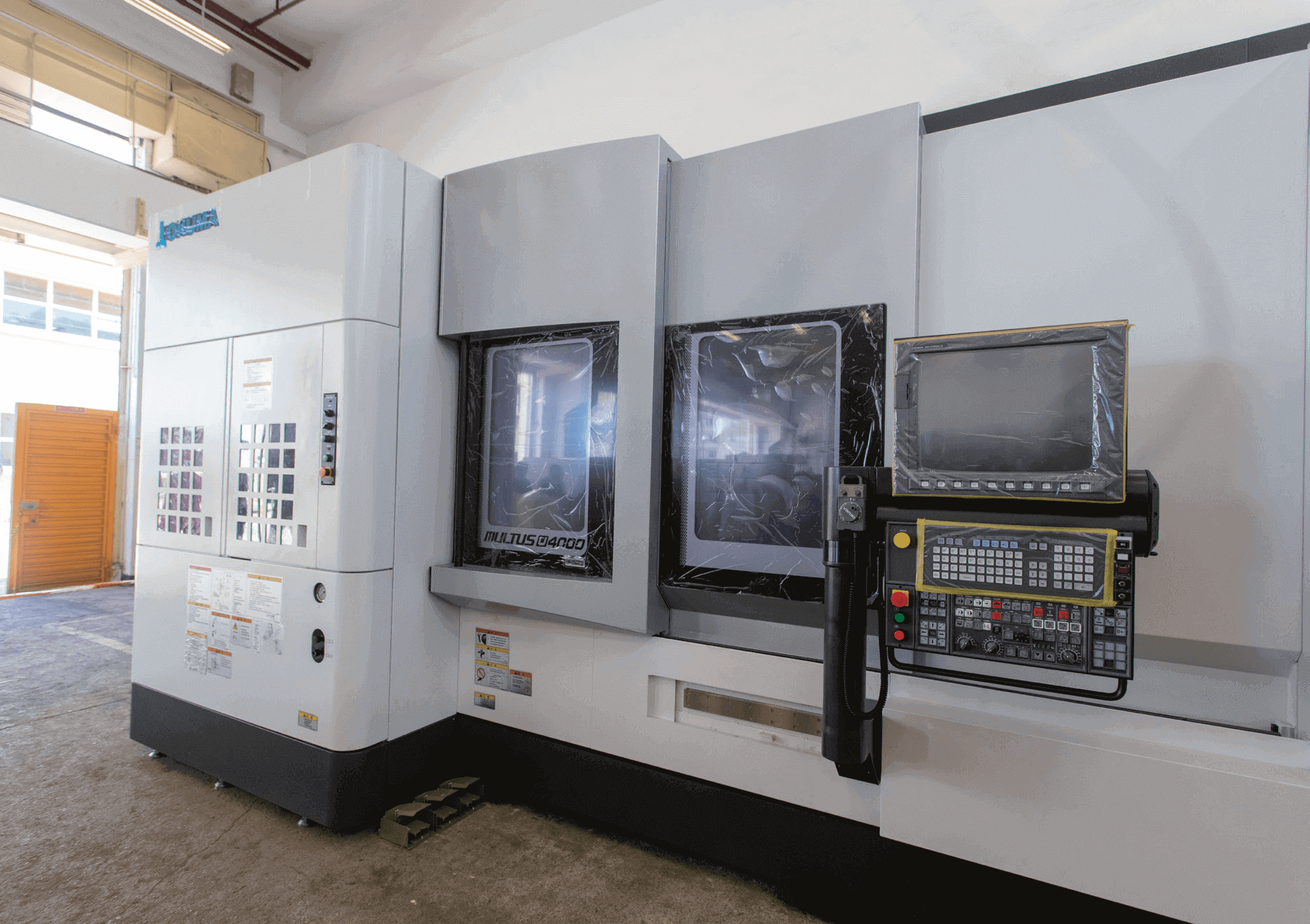

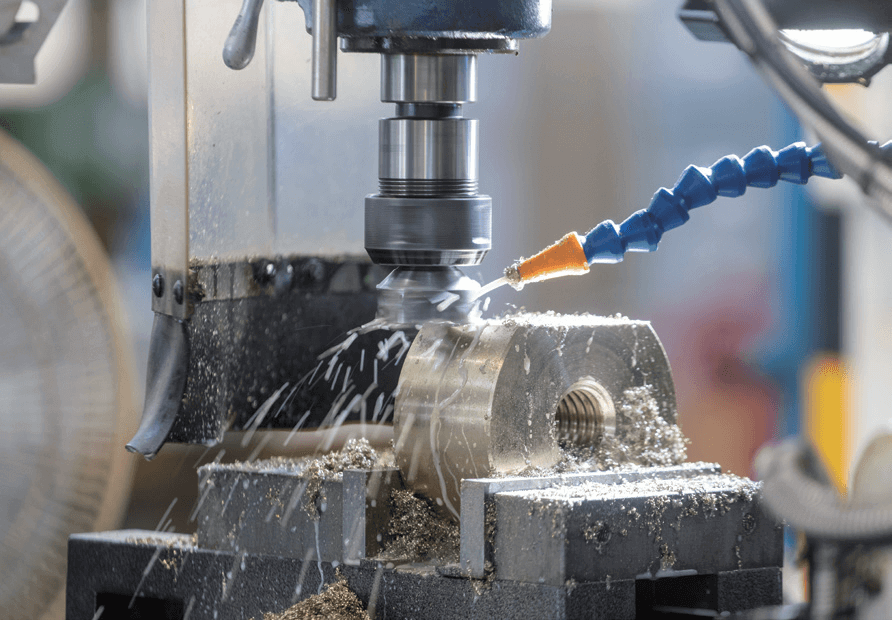

Also, another technological development is the installation in 2022 of a 5-Axis Computer Numerical Control Machine. Similar to three-dimensional replication technology, this machine fabricates machine components that are no longer in production. This technology will assist in extending the life of the WSD’s facilities and preventing facility obsolescence solely due to any discontinuation of the supply of individual components.

Three Generations of Craftsmanship and Workmanship

Ir LAU says that in recent years, the WSD has been committed to improving its service quality, energy management and asset management by respectively obtaining ISO9001, ISO50001 and ISO55001 accreditation. He believes that, “The maintenance division is particularly proud that there are fathers and sons, and even family members from three generations working together, similar to artisan workshops of the past. All our maintenance staff can learn a skill and land a decent job that gives great work satisfaction.”

Mechanical and Electrical Workshop Tour

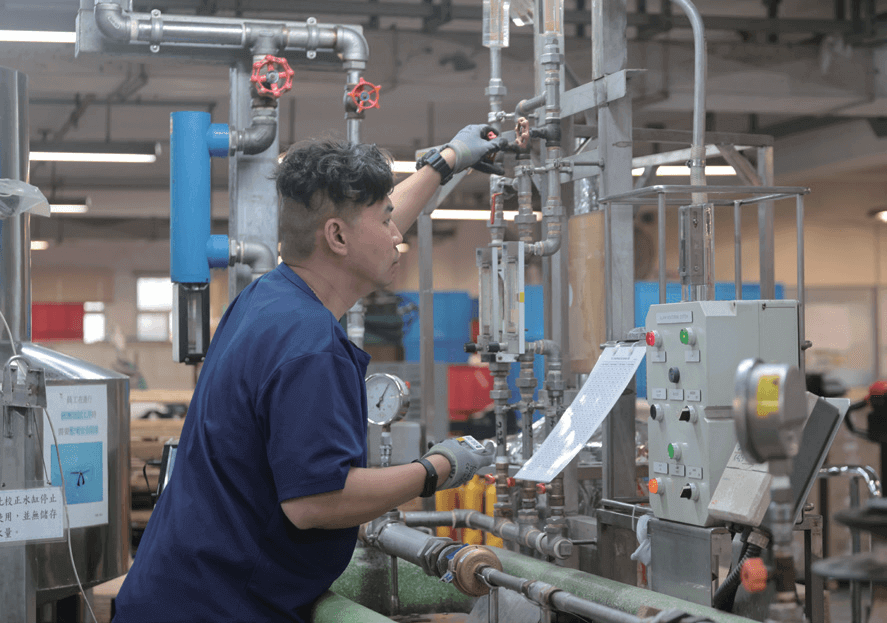

The water supply system comprises over 700 pumps of varying sizes located in pumping stations, water treatment works and service reservoirs. These pumps are responsible for delivering water to all parts of the city. It is crucial that they operate efficiently to prevent any interruption in the water supply. The maintenance team regularly monitors pump efficiency by listening to machinery sounds, measuring motor temperature and voltage, and comparing the electricity consumption with water output. This ensures that the pumps are maintained in good condition.

The optimum lifespan for a pump typically ranges from 15,000 to 50,000 hours, depending on the model. Once a machine reaches its service life, it must be returned to the workshop for maintenance. For example, huge effort is required to transport the WSD’s largest pump, responsible for delivering Dongjiang water to Hong Kong, from the city’s northern district to the M&E workshop at Lung Cheung Road for repair.

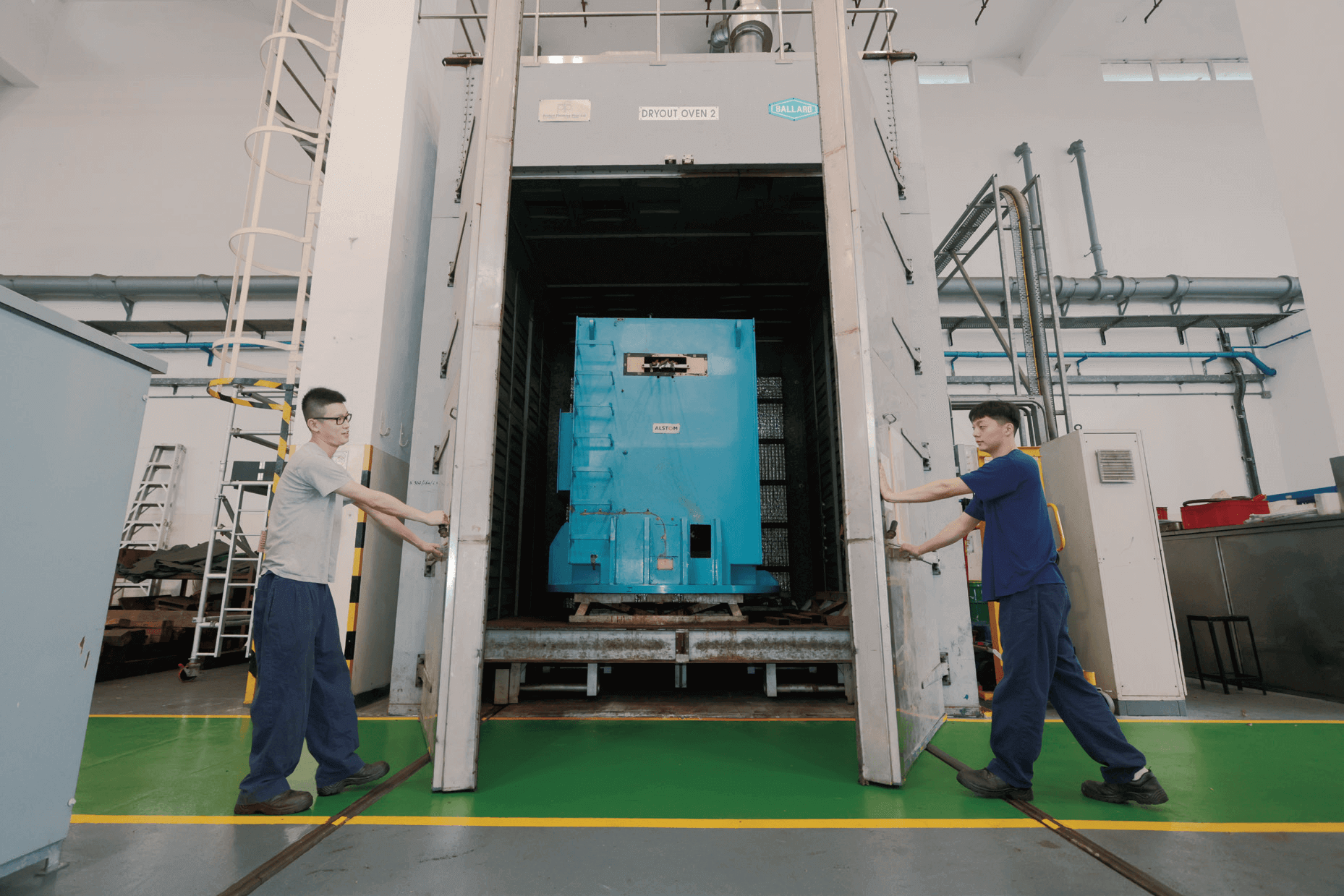

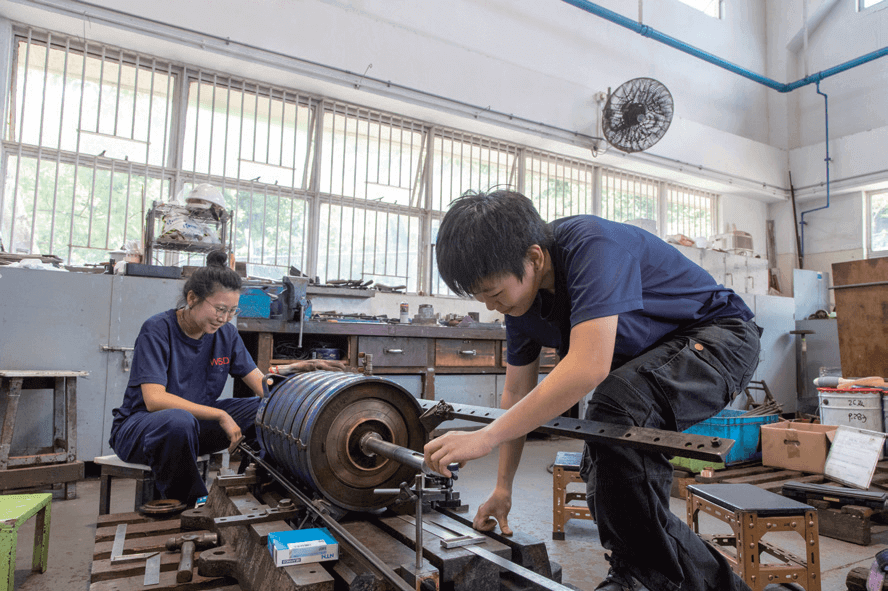

WSD's facilities have a total of 700 motors which form the primary component in its operating pumps. On average, they require maintenance after four to six years of operation. Larger motors, with a power capacity of over 37 kW, must be dismantled and sent back to the workshop for repair due to their size. In most cases, these motors only require routine inspection and have no serious problems. Workshop staff will test each motor to determine if its performance has deteriorated. Staff will firstly disassemble the motor components one-by-one, checking for worn bearings or deterioration of the protective film on coils, then, associated cleaning and maintenance will be done, as necessary. Once the components are reassembled, the motor will be dried in a motor baking oven before its return to the relevant facility.

The largest motor baking oven in the workshop is over two-storey high. Motors located at the Muk Wu pumping station (see photograph below), for example, are the largest of their kind and need to be baked at 105°C for nearly 100 hours, or about four days, after their maintenance. The total time required to repair this type of motor is about two to three weeks.

The residential water meter is the most commonly used water service equipment in Hong Kong households for recording water consumption and calculating water bills. Accuracy is crucial to ensure fairness to customers. The water meters currently used in Hong Kong are imported. Each new water meter has been tested in the manufacturer’s factory and the WSD conducts sample tests to ensure accuracy. In the past, people used a trick for reducing the water bill by dripping the tap to prevent the meter from ticking-over. This urban myth will be further explained in the Chapter 4 article "The Development of Hong Kong’s Water Meters".

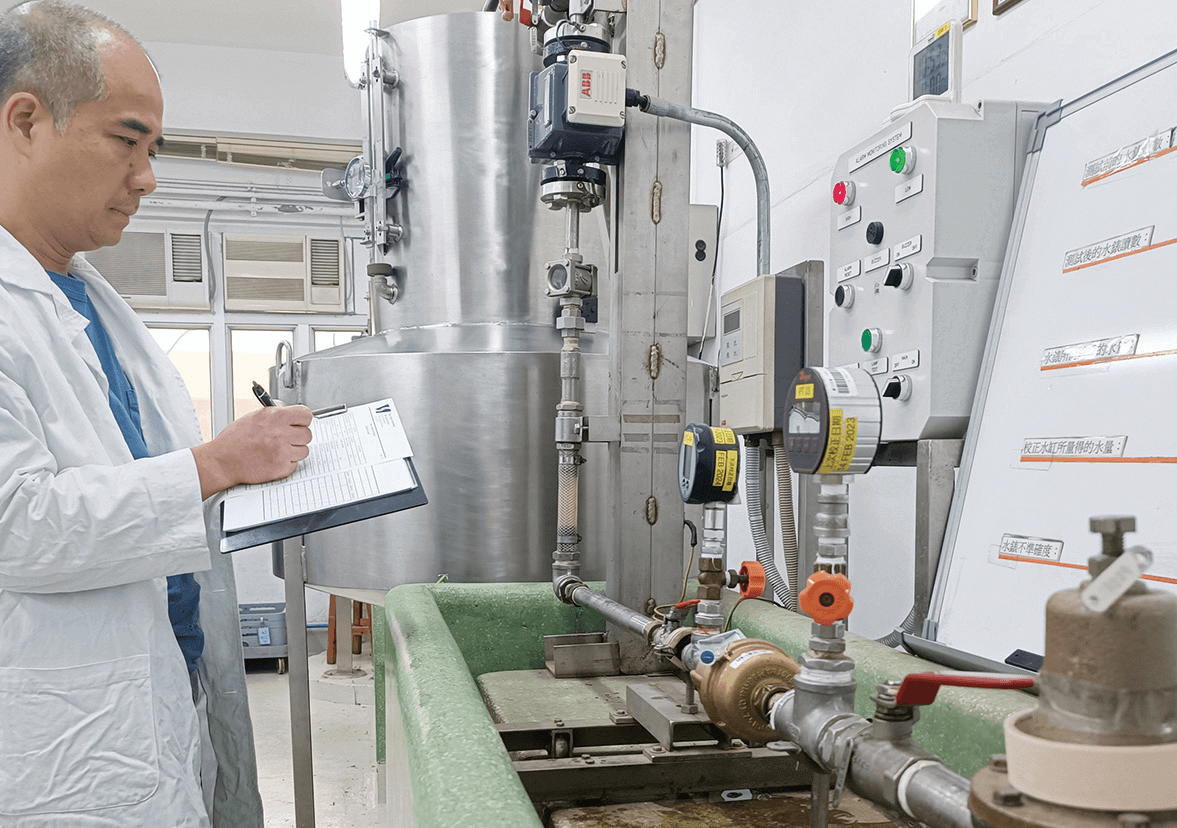

The M&E Workshop at Lung Cheung Road also includes two units: the Metershop and the Meter Testing Laboratory. The former mainly conducts quality assurance testing for newly procured water meters, while the latter is an accredited laboratory providing meter accuracy testing services for the public as well as for the Department’s internal use. If a customer disputes the accuracy of their water meter, they can apply for a meter test. The meter will be removed and delivered to the Meter Testing Laboratory for testing. The WSD will invite the customer to witness the testing process. If the meter proves to be more than 3% inaccurate, the water and sewerage charges will be adjusted accordingly and no charge shall be payable for the meter testing. However, if the meter proves accurate, the customer will be required to pay the meter test fee.

The WSD currently serves approximately three million customers and has a similar number of water meters in service. A typical household water meter measures consumption in cubic metres using an eight-digit indicator with decimal point accuracy. The upper measurement limit of the meter is 9,999 m³. Currently, the average water consumption per person in Hong Kong is about 130 litres per day and, on average, a family of four consumes about 190 m³ of water annually. In theory, the meter will not reach its capacity limit for several decades. However, to ensure their normal operation, the WSD arranges for their replacement on a regular basis. Every year, the WSD reviews the data of all water meters in Hong Kong, including their service life, usage rate (i.e. cumulative total flow rate) and average monthly flow rate, and other relevant factors. Meters are monitored for a higher rate of wear-and-tear, and preventive replacement is arranged if necessary.

A customers’ water service system inside their private premises is not under the purview of the WSD. However, the HKSAR Government launched the "Action Plan for Enhancing Drinking Water Safety in Hong Kong" in 2017 (please refer to the article "A Lead-free Water Supply System" in Chapter 5 for details). This plan proposes stronger regulation of plumbing materials. The WSD has now implemented a pre-approval system for plumbing products, which after approval are known as ‘General Acceptance (GA) products’. To further enhance verification that GA plumbing products meet GA requirements after their qualification, the WSD is implementing a monitoring plan for all GA products. Samples of GA products are randomly selected by the WSD and tested in the M&E Workshop’s Material Testing Laboratory. The range of GA products cover water pipes, water pipe fittings, solder, valves (pressure reducing valves) and toilet flush valves.

To ensure drinking water safety, product samples must pass monitoring tests for their chemical composition (e.g. metal elements of metal parts in direct contact with drinking water) and the main functions of plumbing devices to ensure they meet specification requirements.

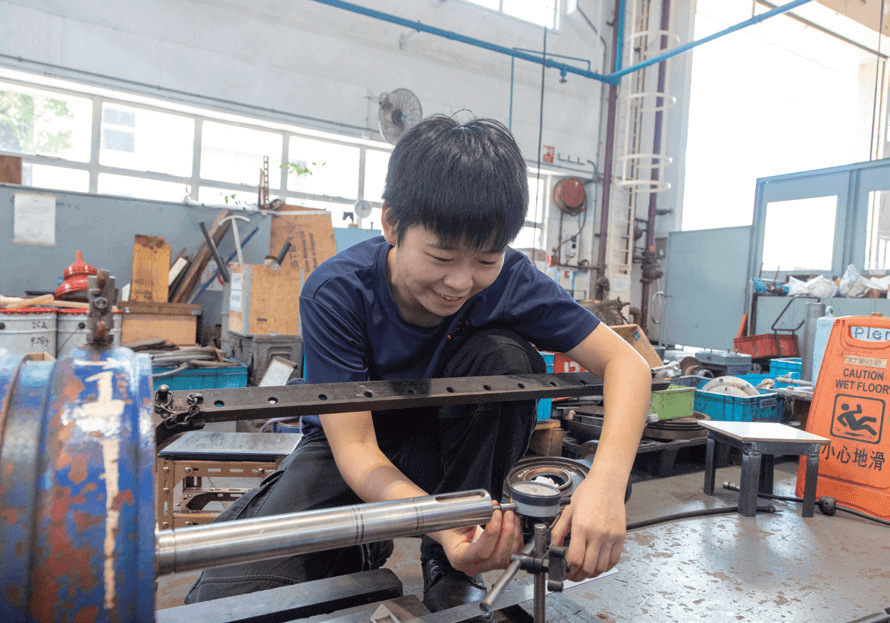

Every year, the WSD and the Electrical and Mechanical Services Department (EMSD) jointly recruit staff for Technician Trainees II positions. Recently, the training programme has been streamlined to run for a two-year duration, in response to feedback, enabling trainees to attain the qualification of Technician Trainee II quicker. Each year, the WSD recruits between three to six Technician Trainees II (Mechanical), and one or two Technician Trainees II (Electrical) to participate in the training programme. Trainees attend theory courses at the Hong Kong Institute of Vocational Education each week, during which they undergo a mechanical or electrical internship programme with the WSD.

Participants will be assigned to different units during the internship, including in the Metershop, regional mechanical maintenance teams, the mechanical and electrical workshops, regional electrical maintenance teams, electrical protection and testing teams, etc. Graduates are eligible to apply to become government artisans after completing the training programme.

- This Chinese acronym refers to the skills required for operating the lathe, milling machine, planer, grinder and drilling machine.