The WSD manages and maintains a water distribution network spanning over 8,000 km. Over the years, the WSD has proactively conducted regular leak detection of water mains throughout the city for the early identification and repair of leaks. Nonetheless, identification of potential issues remains challenging due to the expansive and complexity of Hong Kong's water distribution system, and as many of the water mains lie deep beneath the ground.

Due to evolving technology, the WSD has made considerable effort to improve its distribution network management by establishing Water Intelligent Network (WIN). Zones within the fresh water distribution network have been established to monitor and gather data, allowing for quick decision-making and using best network management methods to minimise water loss due to leakage in the water mains. The WSD aims to further reduce the leakage rate of its water mains to less than 10% by the end of 2030.

“The continuous monitoring and data analysis provided by WIN gives us a more accurate picture of the condition of the water distribution network, including water pressure and consumption. This enables us to identify and follow-up on areas where water loss is suspected, and allows us to maximise our efficiency with limited resources,” says Chief Engineer of the Development Branch, Ir Simon LEUNG Chi-hung.

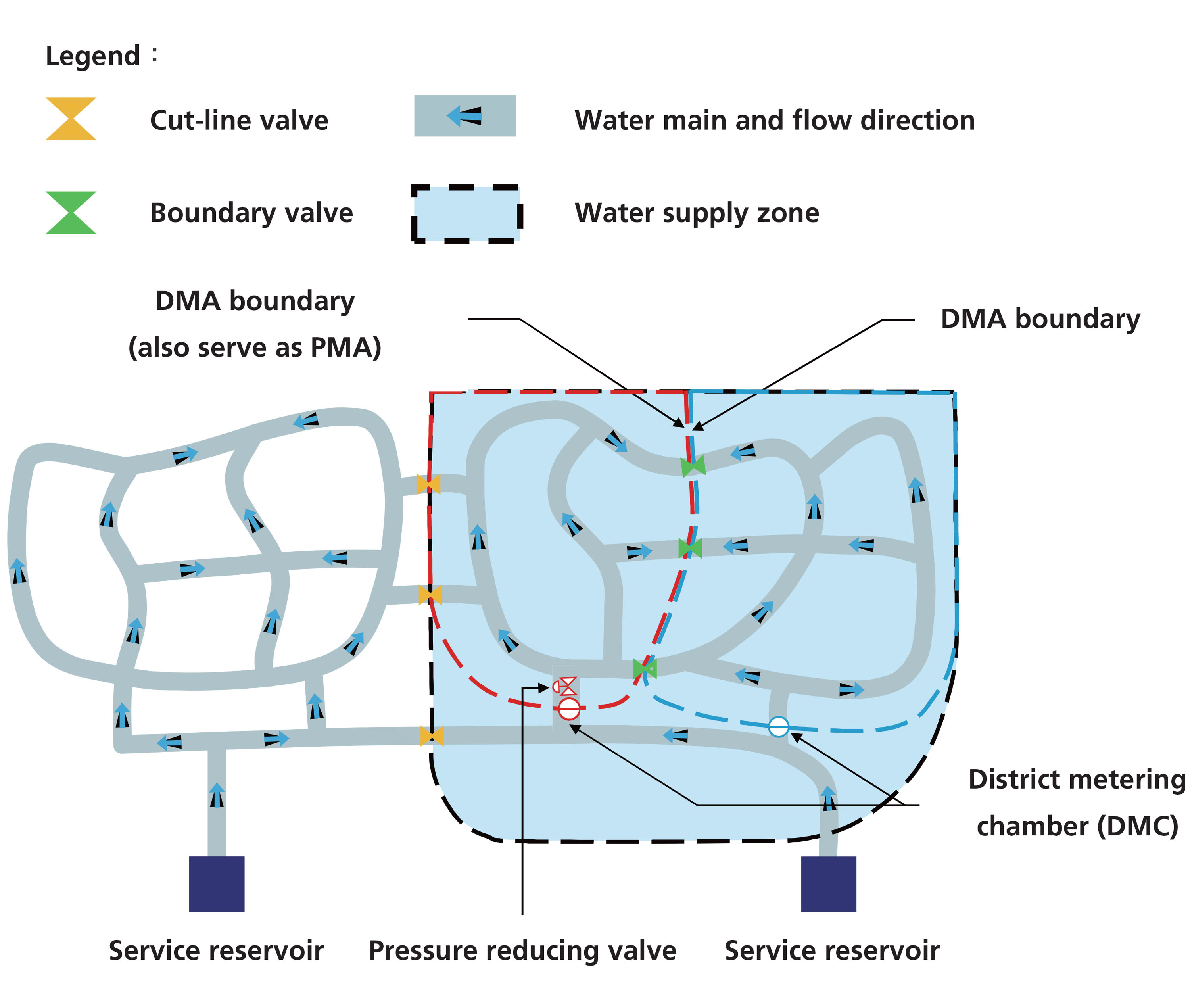

Concept of Zone Monitoring

Zone monitoring was initially developed in the United Kingdom during the 1980s. It involves creating a distinct sector within a water distribution network by closing boundary valves or disconnecting water mains. Flow meters and pressure sensors are used to monitor water flow and pressure into respective areas. Analysis to assess potential water mains leaks is done during night-time, a time of low water flow. "Using smart technology, data collection has become fully automated with more monitoring points available to continuously monitor flow and water pressure, resulting in more accurate and efficient management.”

The Water Intelligent Network (WIN)

WIN is a system through which the WSD employs monitoring and sensing equipment to automatically collect continuous 24-hour water flow and pressure data for computer analysis to monitor water loss in a region. Around 2,400 individual District Metering Areas (DMAs) will be installed in the existing water distribution network, based on various factors, such as structural condition, coverage, length of water mains, topography, number and type of consumers.

Without compromising the minimum water pressure required to maintain a normal water supply, the WSD will install pressure reducing valves in the DMA to establish a "pressure management area" (PMA), aiming to implement pressure management, reduce water pressure and minimise water mains leakage. (For further information on water management, please refer to the article “The Principles Behind Hong Kong’s Unique Water Distribution Systems” in this chapter.)

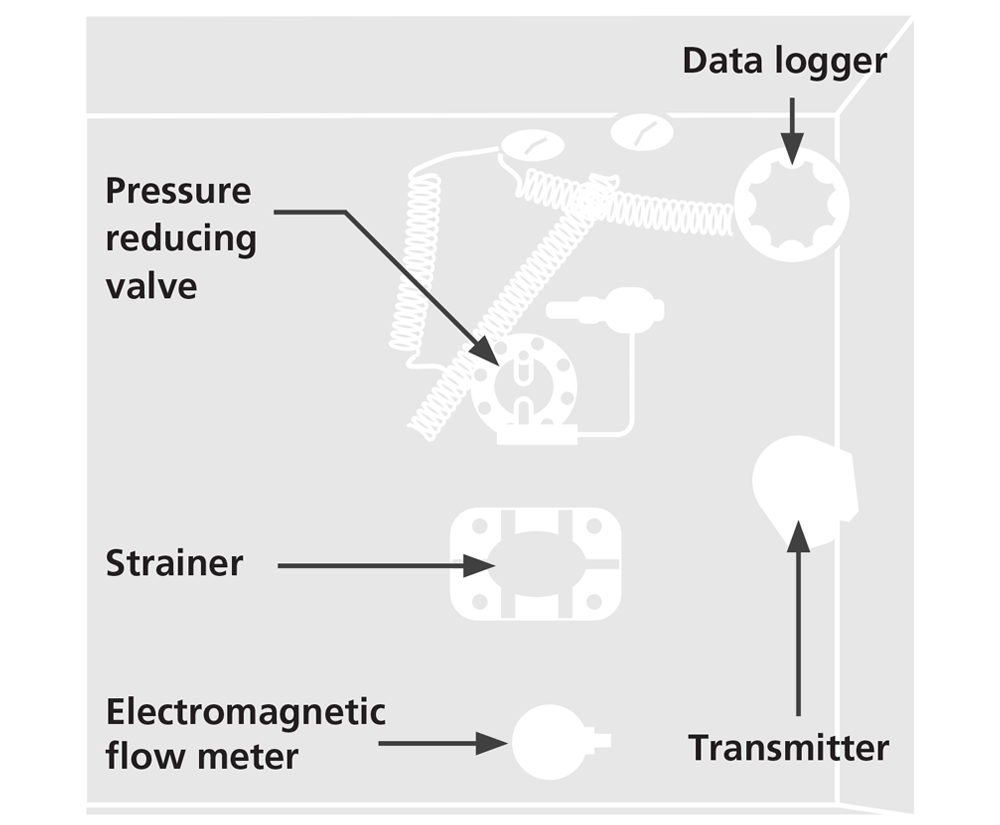

Diagram showing the Water Intelligent Network operations

A flow-meter and a pressure data logger will be installed in each individual monitoring area, allowing the efficient collection of water flow and pressure data to monitor water loss in an area. Such monitoring allows the implementation of targeted measures, such as active leakage detection, pressure management, speedy repair of water mains leaks, and replacement or rehabilitation of water mains, etc.

The WSD has established about 1,900 DMAs by September 2023. By analysing the collected data, the WSD conducts further investigation of areas with suspected leakage for follow-up and repair. These repairs have resulted in a substantial reduction in water loss.

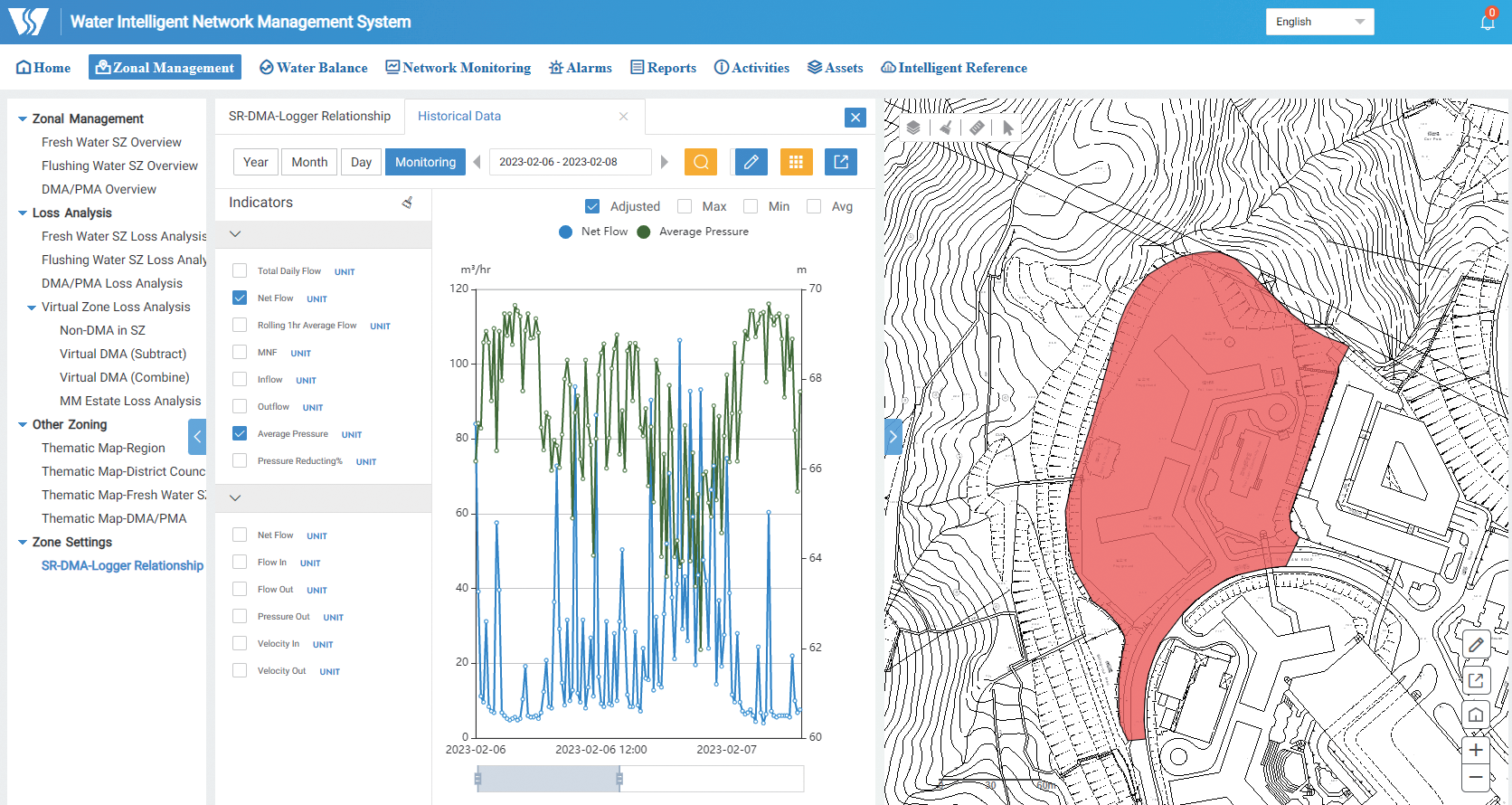

Water Intelligent Network Management System

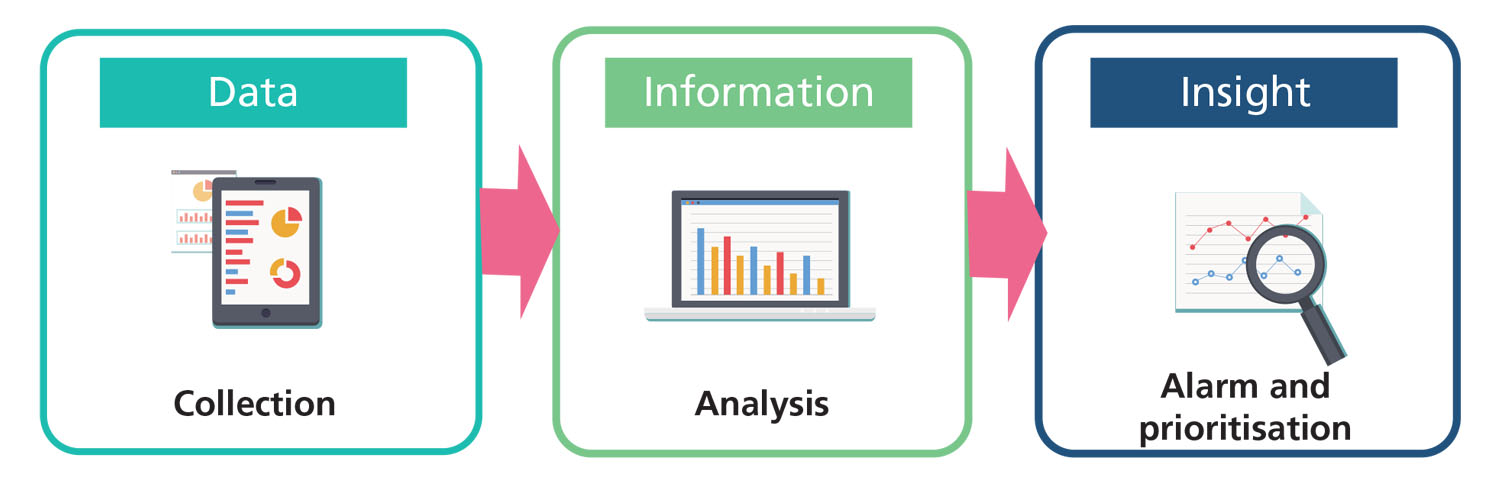

In 2020, the WSD launched the Water Intelligent Network Management System (INMS), which collects data from DMAs and PMAs and uploads them to the computer monitoring system for management and analysis. By using WIN, the WSD staff can identify anomalies in the water distribution network at an early stage, and support the development of cost-effective solutions and prioritise its implementation.

Schematic Diagram of the Water Intelligent Network Management System

Water Mains Leak Detection

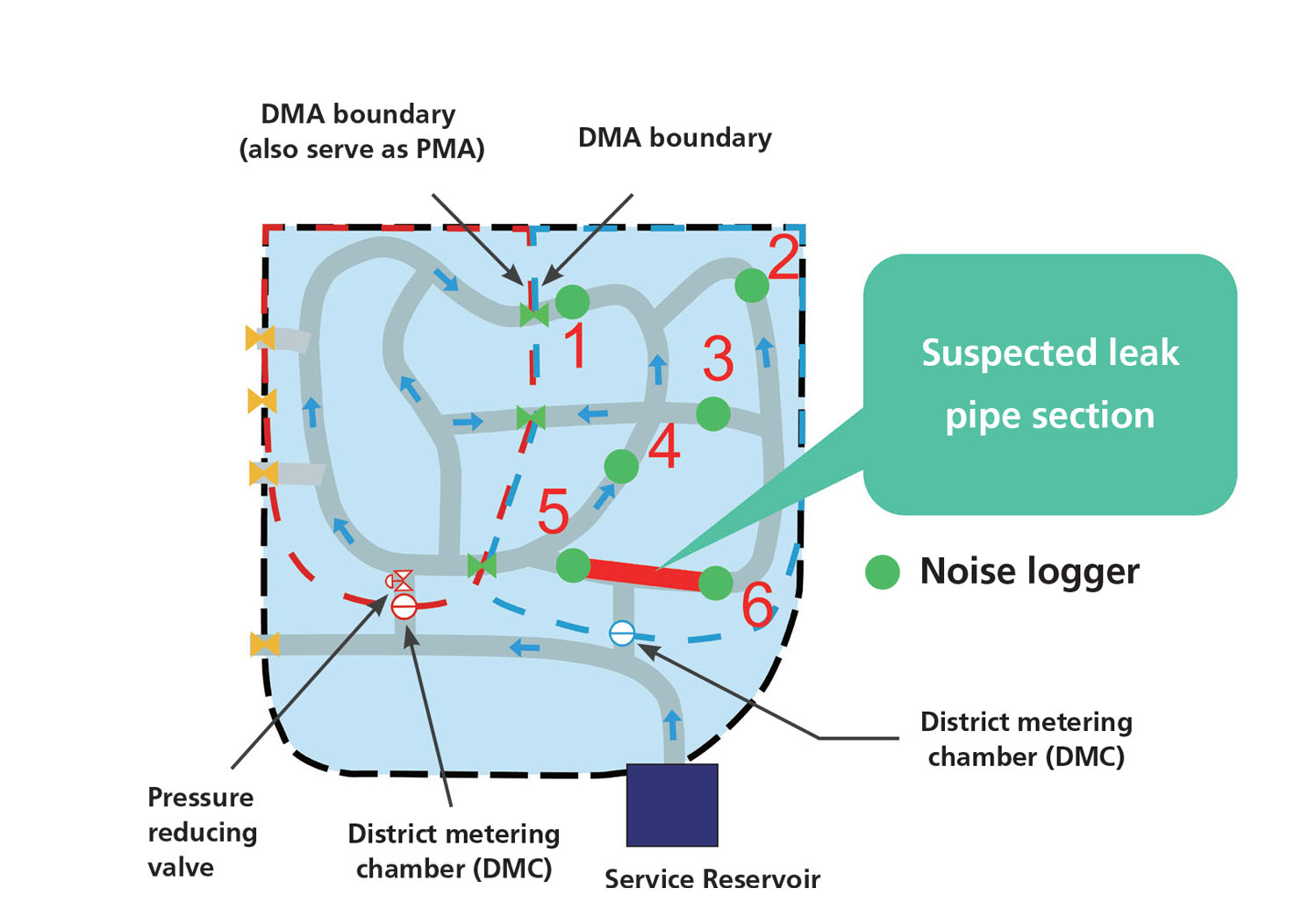

If any anomaly is detected in the network data of a specific DMA, the WSD will conduct an investigation in that area. Once the suspected section of the pipe is identified, the next step is locating the leak points along the underground water mains by performing tests. Then, WSD staff will identify the leaking pipe and locate the leakage point for repair.

Pipe Leakage Detection: Locating Suspected Leaking Pipe Sections

Water pressure in the pipe generates noise at the leak point which travels along both sides of a pipe. Installing noise loggers enables a repair crew to identify the possible location of any suspected section of pipe leakage. Noise loggers automatically activate every night at a set time (typically late night between 2 a.m. and 4 a.m., when the surroundings are quiet), to record any detected noise from the pipes. After analysing the captured soundwaves, the system has the ability to detect any indication of potential leaks in the adjacent pipes, facilitating further inspection of suspected leaking pipes by frontline staff.

Leakage Detection

Leak Noise Correlation: Narrowing Down a Leak Area

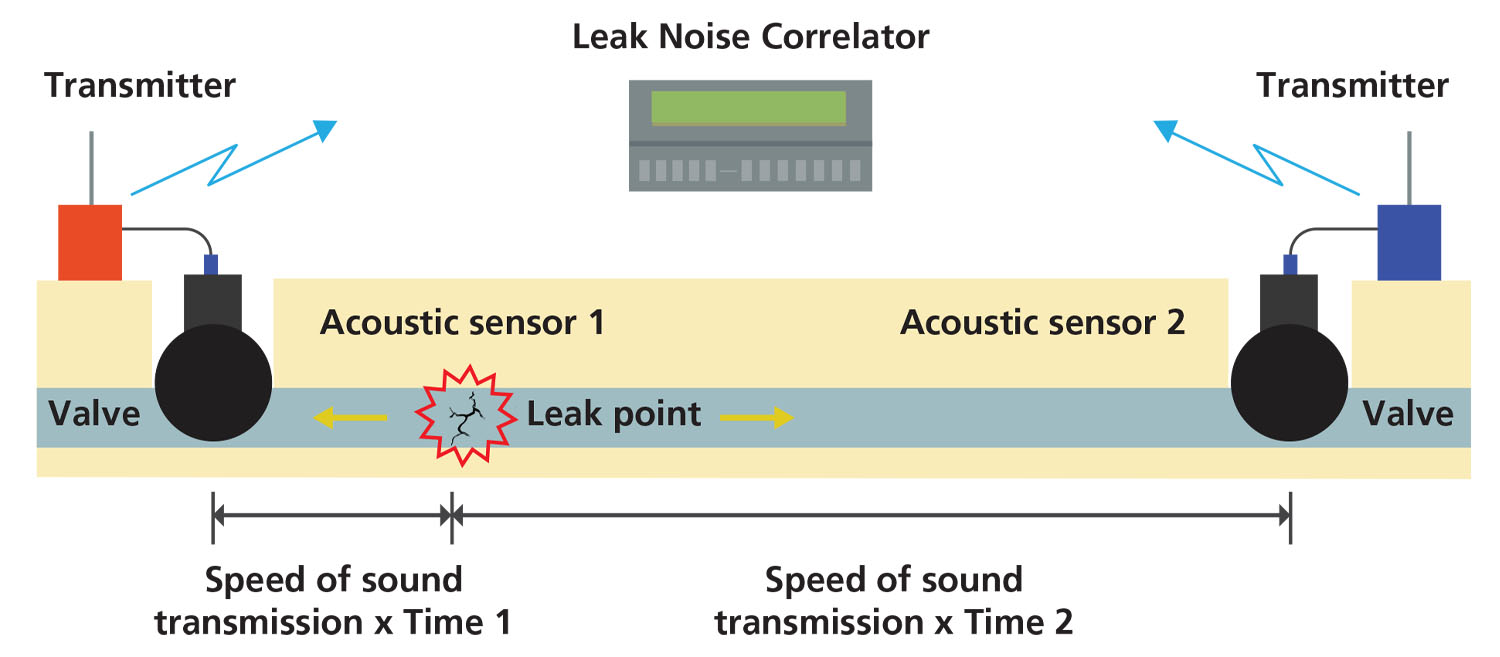

As the sound wave of a water leak travels along both sides of the pipe, the closer to the leak, the earlier the same noise is detected. Two sensors will be installed at locations with access to the pipe, e.g. the pipe valve. Details such as the pipe’s length, diameter and material will be inputted. Afterwards, the correlator will calculate the relative distance between the two sensors by comparing the time difference when both sensors receive the same noise.

Principle of Leak Noise Correlator

Leak Points Identification

Based on the results of the leak noise correlator, staff will use a stethoscope or ground microphone to listen for leaks along the pipe's path and identify the leak point. The stethoscope's design amplifies the leak's sound like a cochlear hearing implant. With the stethoscope directly placed on the ground, skilled and experienced staff can detect the sound and locate the leak point accurately. The ground microphone operates on the same principle, with additional features including the ability to measure sound levels in decibels and perform audio filtering. Leak detection is conducted at night, if required, to reduce noise interference from the surroundings.

Leakage Detection for Large Diameter Pipes: In-line Detection Technology

Most of the leak detection methods in the industry rely on acoustic principles to detect water leaks in pipes. Nevertheless, the intensity of the noise or the decrease in the transmission of the leak will be affected by the material, dimensions, environment, and water pressure of the pipe. For instance, in the case of larger pipes (i.e. pipes exceeding 600 mm in diameter), the above technique may not be sufficient to locate a defective pipe. As a result, additional leak detection equipment, namely in-line detection techniques, may have to be employed.

The WSD has adopted in-line detection technology for leak detection, which involves inserting an aluminum-core ball with a sound sensor inside at the inlet point of a pressurised pipe. As the ball travels along the water flow, the sound is recorded through the pipe. The sound level is usually higher where there is a leak. The ball simultaneously records the location of the noise, helping frontline staff carry out further investigations and repairs.

Q-Leak, the Underground Water Mains Leak Detection Training Centre

The most reliable way to identify the location of leaks is still by noise recognition. However, as the actual environment is highly variable, frontline staff need to gain experience of leak detection by listening or by using instruments in different practice settings. The introduction of big data analysis can help improve the efficiency and accuracy of detection. Consequently, the WSD worked with the Hong Kong Polytechnic University to design and build a underground water mains leakage detection training centre, Q-Leak in 2020. The centre opened in July 2021 to train staff in water mains leakage detection.

Q-Leak plays an important role in the training and research of leak detection, as follows:

Provide Leak Detection Training for WSD Staff

Q-leak is a water mains leak detection training venue, providing staff with basic knowledge on the procedures and steps required for leak detection, the operation of equipment and the identification of leak sounds.

The road and pipe networks in Hong Kong are extremely intricate. Leakage noise varies depending on the material and diameters of the networks’ pipes. Therefore, the WSD has laid a network of water pipes with varying sizes and material, extending over a total length of around 400 metres in the 2,000-square-metre Q-Leak training area. The road surface is also paved with different materials, such as grass bricks, concrete and asphalt to imitate diverse ground coverings, water pipes and road conditions. Various devices, including valves and pressure reducing valves, have been installed in the network to replicate the various modes of water flow.

There are more than 80 simulated leak points on the training ground, where trainees can practise using various types of leak detection instruments in different environments. They can also conduct visual and sounding inspections, noise recording and step tests to narrow down the area of suspected leaking pipes.

Establishment of Industry Accreditation

Apart from government water mains, leaks are also occasionally found in the underground water pipes of private properties. The demand for leak detection in the private sector is expected to grow in the future. The establishment of Q-Leak is a good opportunity to provide the local water industry with appropriate training to identify, access and learn to use the latest leak detection instruments to improve their skills.

Q-Leak also facilitates the assessment of skills in the industry. Due to the versatile arrangement of potential leakage points in the training area, blind tests can be varied, from easy to difficult, to test the full range of leak detection skills of trainees.

Development of Leak Detection Techniques for Hong Kong's Unique Conditions

Building a Sound Spectrum of Water Leaks

Currently, traditional leak detection techniques remain more accurate and reliable than advanced electronic leak detection equipment. Veteran professionals, who possess years of experience, can precisely identify the sounds of water leaking. However, this level of craftsmanship is challenging to pass on and the art will be lost as these experts gradually retire. The new leak detection equipment records the sound emanating from leaking pipes, which can be compiled into a database. In combination with the data collected from other sensors, analysis and learning are made easier.

In fact, every leak produces a distinct sound spectrum. The sound emitted by a leaking plastic pipe or steel pipe differs from the one transmitted through paving blocks or a concrete pavement. Many water leaks can be analysed by artificial intelligence (AI) to recognise acoustic patterns and their correlation with water leakage. Upon identifying the associations, the AI can further simulate the frequency of water leakage in pipes of different sizes. If a similar sound spectrum is identified in the future, WSD staff will be capable of detecting leaks quicker, thereby preventing further burst pipes.

Application of Ground Penetrating Radar

Another important objective of the centre’s research is to enhance the efficiency of the leak detection process. The installation of noise loggers is labour intensive and requires road closure, equipment installation in manholes, and data collection lasting one to two days, but the investigation area to be monitored is quite limited. To address these issues, the WSD began collaboration in 2022 with the Hong Kong Polytechnic University to study the application of ground penetrating radar (GPR) technology for detecting water mains leakage.

GPR employs radar pulses to detect conditions below the ground surface. The method involves sending radar pulses to the ground surface, followed by recording and storing the intensity and time taken for the signal to be reflected by different substances. Conducting multiple radar surveys in an area enables the combination of various profiles to produce a comprehensive three-dimensional picture for inspection. Originally, GPR is used for pipeline surveys to detect the location of water mains by using photo images. In order to detect water mains leaks, the team had to capture, identify and define the image characteristics of the leaks. Q-Leak plays an important role in this regard. The team utilised GPR to capture the corresponding image features of different types of leaks at known leak points within the training ground to indicate suspected leak points.

Majority of water mains in Hong Kong are situated underneath carriageways. When the WIN data indicates a suspected leak in a DMA, the WSD staff can use a motorised vehicle to tow a GPR along carriageways in the suspected area. Normally, it takes over a week to gather data from 30 to 40 km of water mains using conventional methods. By employing motorised radar, the same distance can be accomplished in about an hour, with a significant reduction in time and cost.

Water Mains Asset Management Strategy

Risk-based Water Mains Improvements

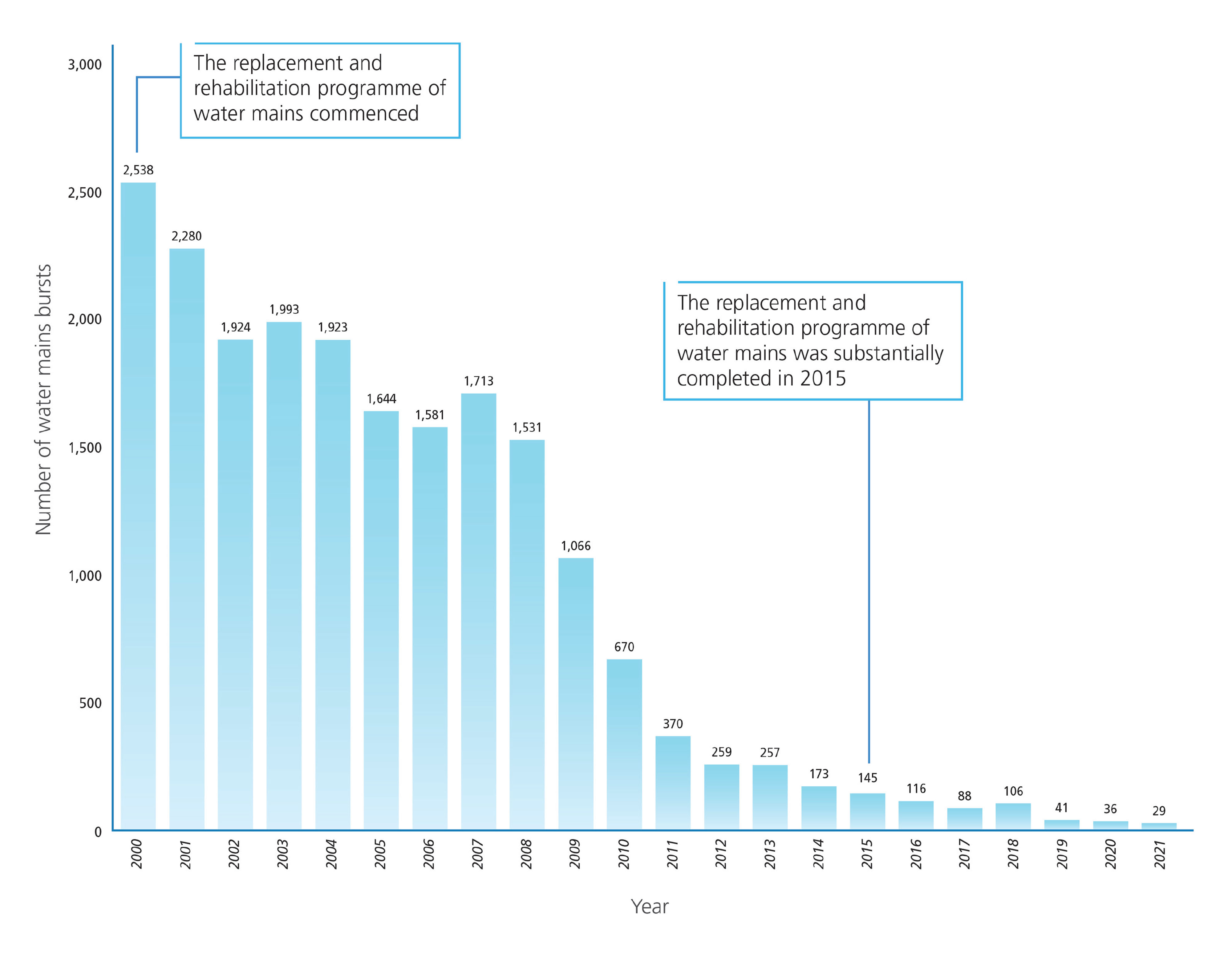

Between 2000 and 2015, the WSD launched a large-scale programme to replace and rehabilitate severely aged pipelines or pipelines with frequent burst mains incidents. Under the programme, the condition of about 3,000 km aged water mains were improved. After major replacement and rehabilitation works, the number of burst mains cases has been significantly reduced by about 90%. As the overall condition of the network improves, large-scale replacement and rehabilitation of water mains is no longer the only effective way to maintain the health of the network. The WSD is seeking more cost effective measures and to balance risk, cost and service levels factors. At present, the WSD is implementing a "Risk-based Water Mains Asset Management Strategy" to maintain the health of water supply networks and reduce the risk of burst water mains and leaks. The WSD will assess the risk, and take into account various factors, including the consequences of bursts or leaks, the age and material of water mains, past records of bursts or leaks, and the surrounding environment, etc. Priority will be given to water mains assessed as a high risk to carry out the required improvement works, thus allowing pipe replacement and rehabilitation works to be conducted systematically to reduce the risk of bursts and leaks. Since the implementation of active leakage control and pressure management on water mains, the condition of the water mains network has improved significantly. The number of burst water mains dropped from over 2,500 in the year of 2000 to an average of 40 or less per year in the past few years, representing a 98% reduction. The associated number of water mains leakage cases also fell in the same period.

Water Mains Burst Cases in Hong Kong, 2000-2021

Water Mains Replacement or Rehabilitation

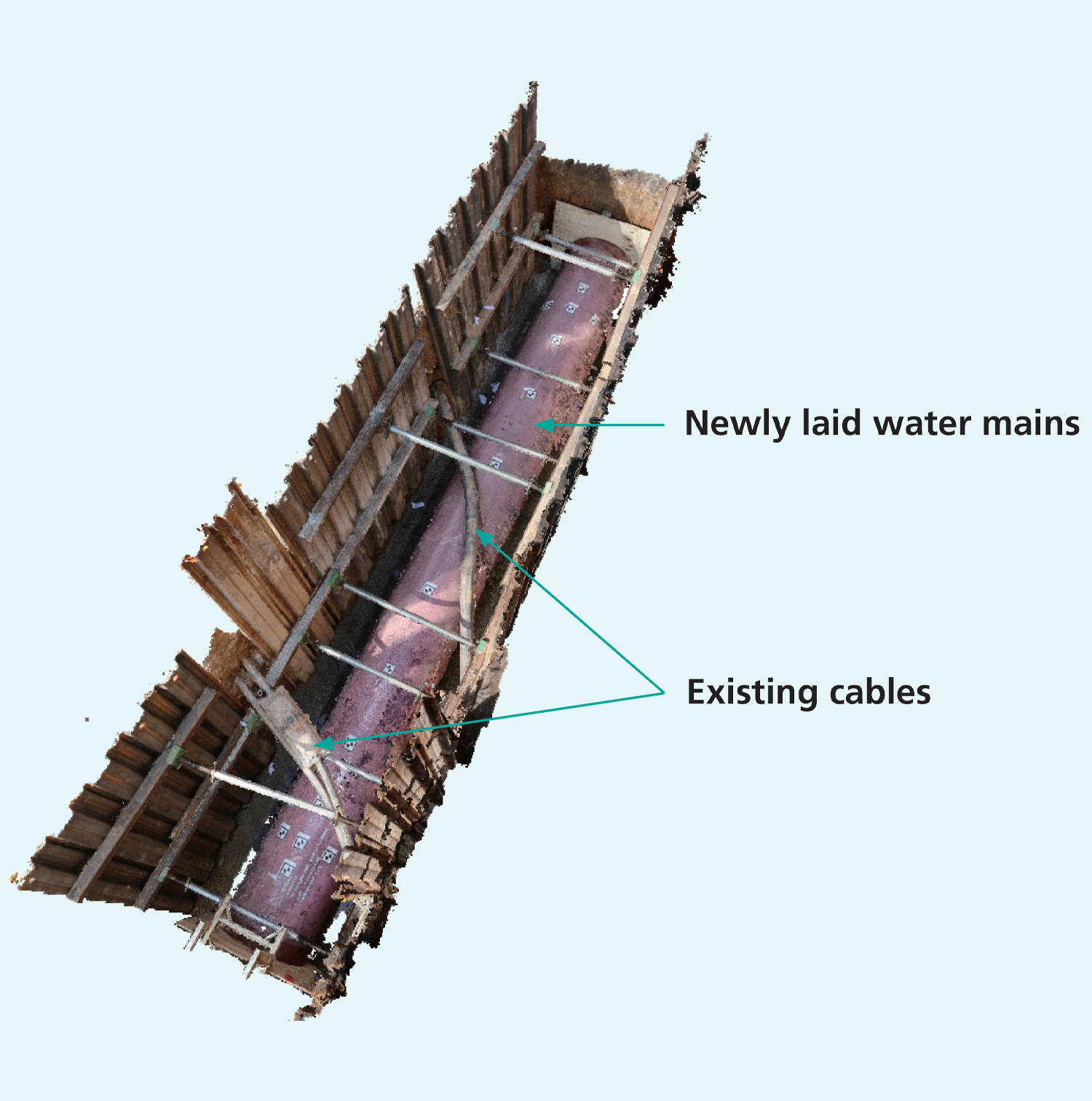

Hong Kong has a dense underground pipe network. Currently, there are about 20 public utilities that frequently carry out road excavation for maintenance works, including for gas piping, fibre optic cables, storm water drainage and electricity cables. The most common issue when constructing water mains networks is the identification of other utilities not shown on a utility’s plans during trench excavations. Therefore, it is often not easy to locate underground water mains alignments for pipe replacement or rehabilitation in developed areas.

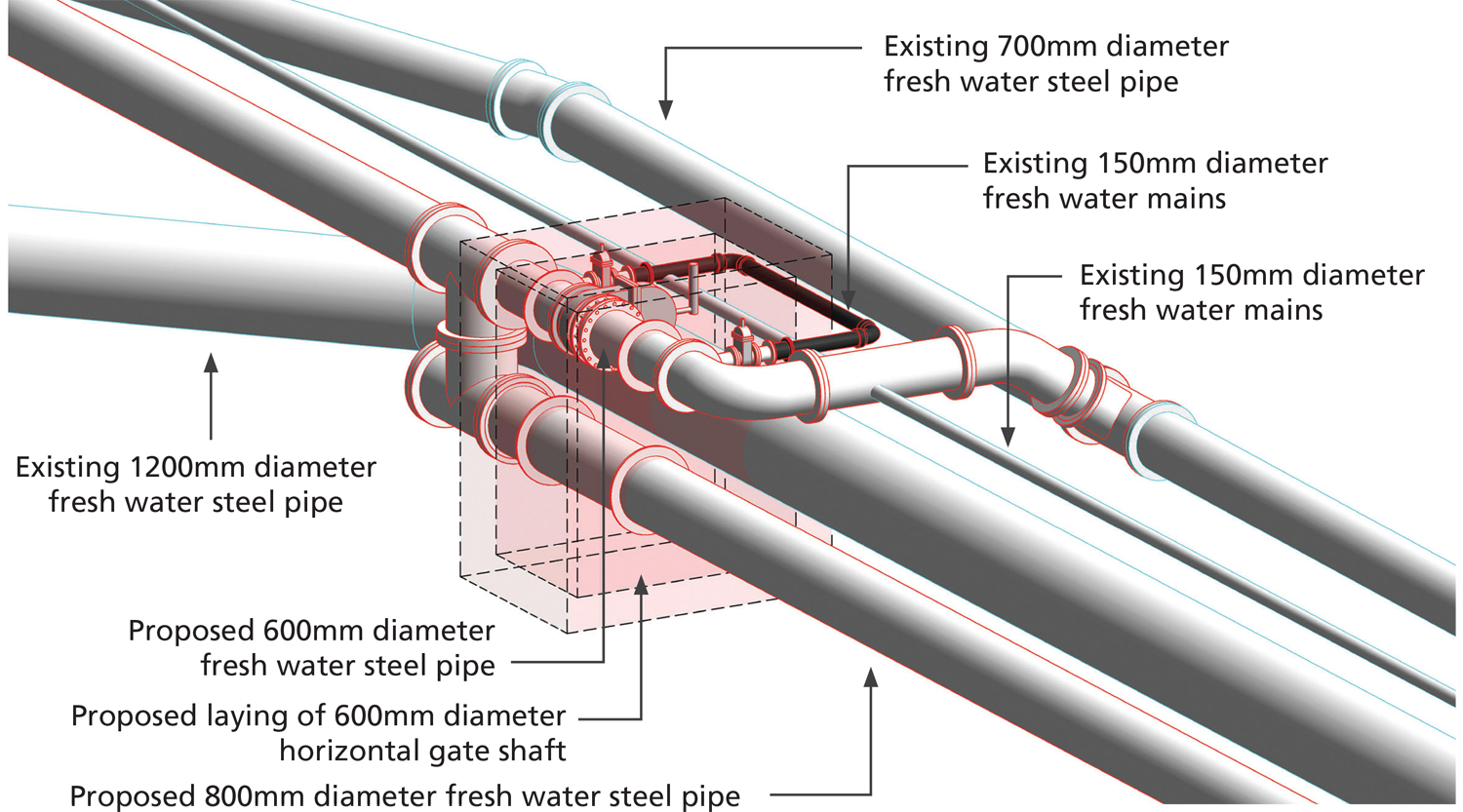

Hong Kong’s water mains are generally laid by open trench excavation, i.e. ground opening, underground water mains laying and subsequent connections. A number of considerations need to be balanced when replacing water mains, particularly the need to avoid conflict with the congested existing underground services as mains are often located deep underground. Another consideration is the impact on water supply to customers and its effect on traffic. At busy road junctions or locations with water mains crossing road sections, the WSD will use "minimum dig" techniques to reduce the impact on traffic.

Building of Water Pipes Information Modelling and Point Cloud Storage

Alignment design of large diameter water mains has always been challenging, as it requires the use of limited available underground space and avoiding conflicting with existing pipe alignments. In the past, water mains were mainly planned in a two-dimensional format, but by using Building Information Modelling (BIM) technology, the WSD can generate a precise three-dimensional elevation, which maximises the visibility of underground spaces. This technology enables the early detection of any potential conflicts between proposed water mains and existing pipes, thus reduces time and cost implication due to delayed detection.

In addition, the WSD is conducting point cloud surveys for all newly installed water mains and underground utility pipes found after trenching. The resulting cloud data will be used to create a BIM model of the water mains. All point cloud data and BIM models will be stored in the WSD's database to provide a more accurate record for designing future water mains. This approach will save time and costs associated with water mains laying and reduce nuisance to the public.